Material of Boron Nitride Ceramics

- Pyrolytic Boron Nitride: 99.99% Boron Nitride*

- UHB: >99.7% Boron Nitride

- HB: >99% Boron Nitride

- BC: >97.5% Boron Nitride

- BAN: Boron Nitride + Aluminum Nitride

- BMZ: Boron Nitride + Zirconium Oxide

- BMA: Boron Nitride + Zirconium Oxide + Aluminum Oxide

- BSC: Boron Nitride + Silicon Carbide

- BMS: Boron Nitride +Silicon Oxide+Aluminum Oxide

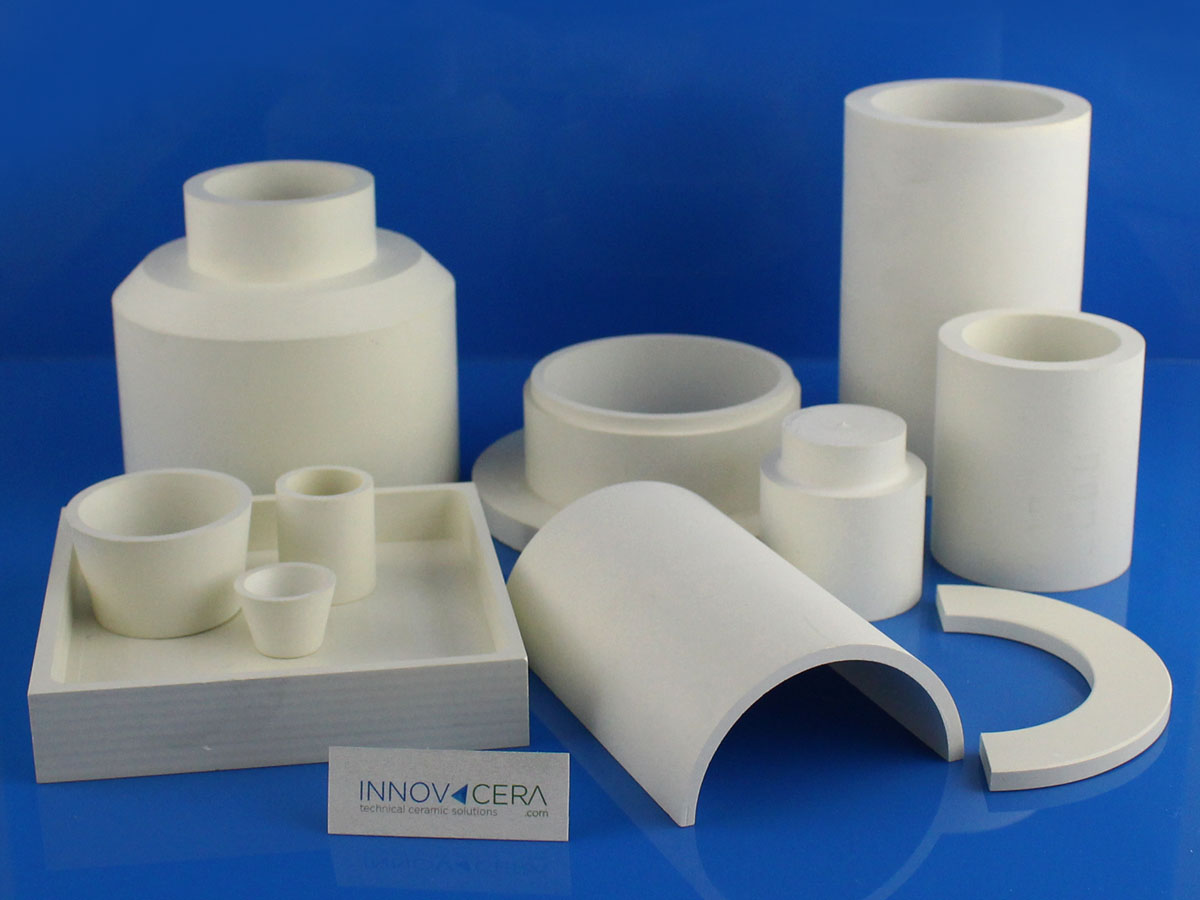

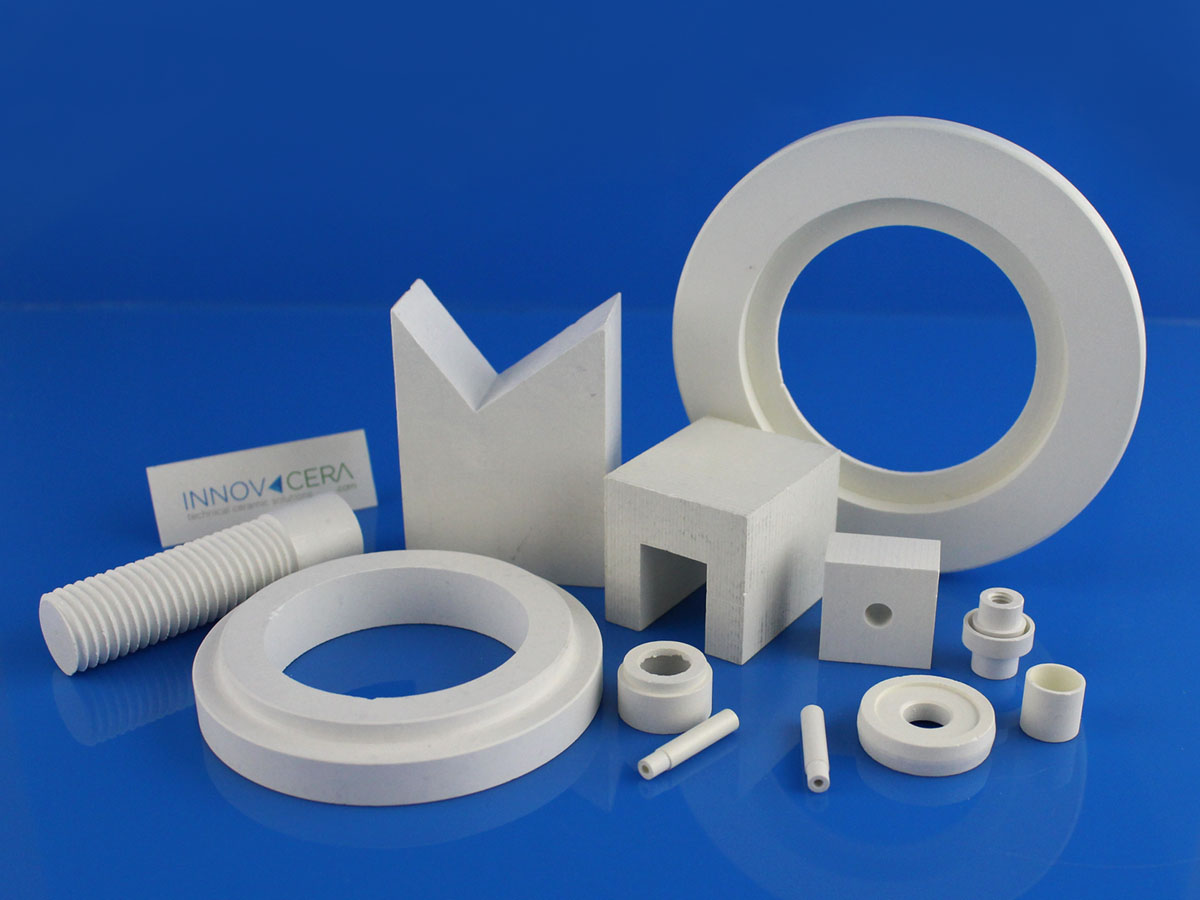

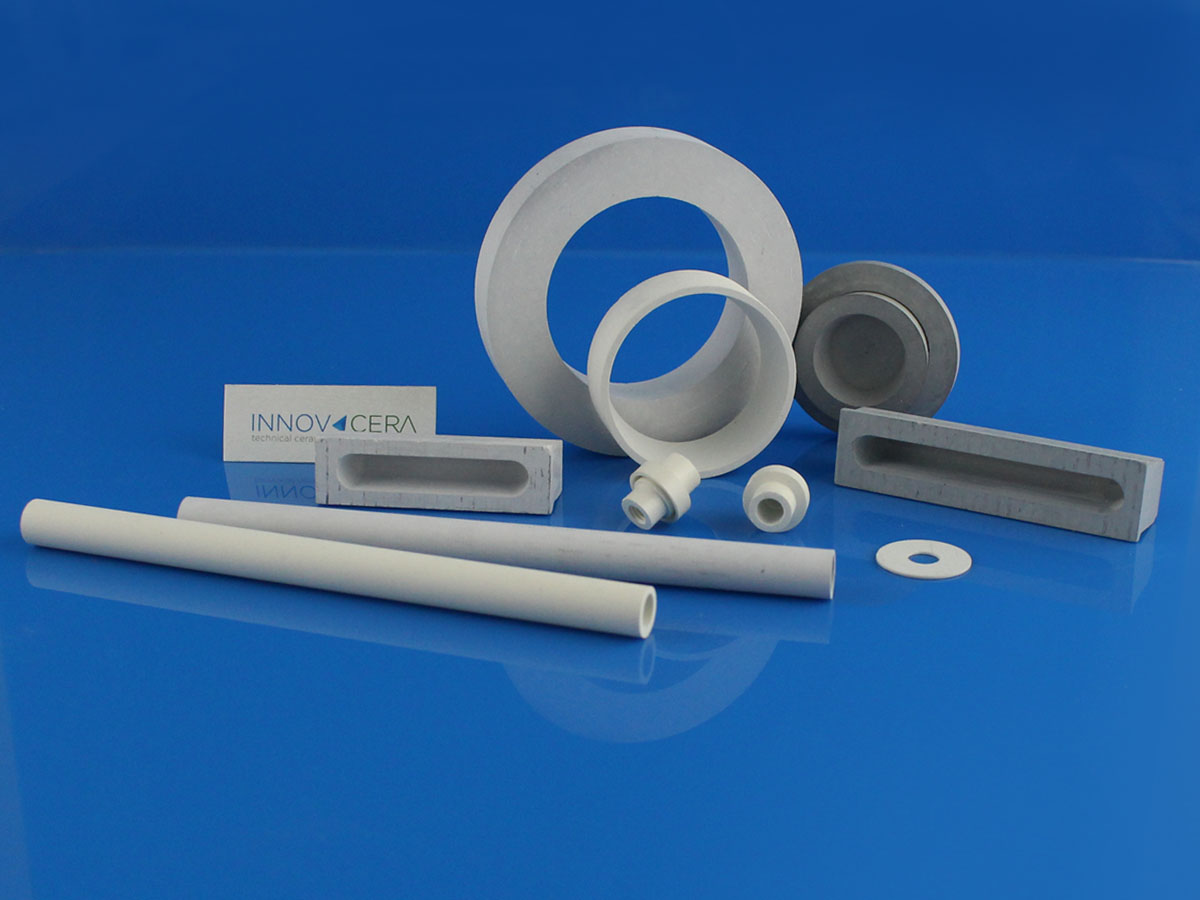

Processing of Boron Nitride Ceramics

- Hot Pressed Sintering

- Chemical Vapor Deposition

Applications of Boron Nitrides Ceramics

-

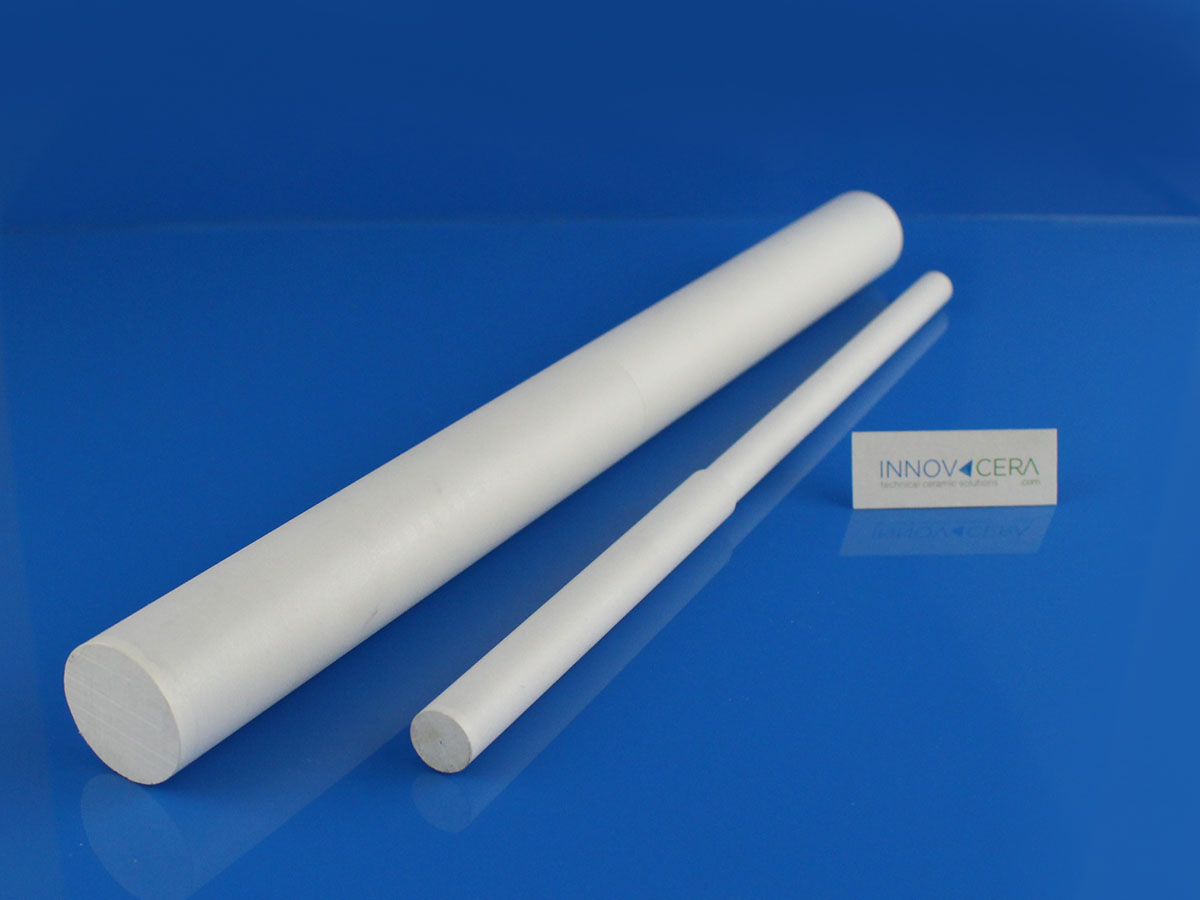

Thermal Management

Excellent electrical insulation and thermal conductivity make BN very useful as a heat sink in high-power electronic applications. Its properties compare favorably with beryllium oxide, aluminum oxide, and other electronic packaging materials, and are easier machinable to desired shapes and sizes.

-

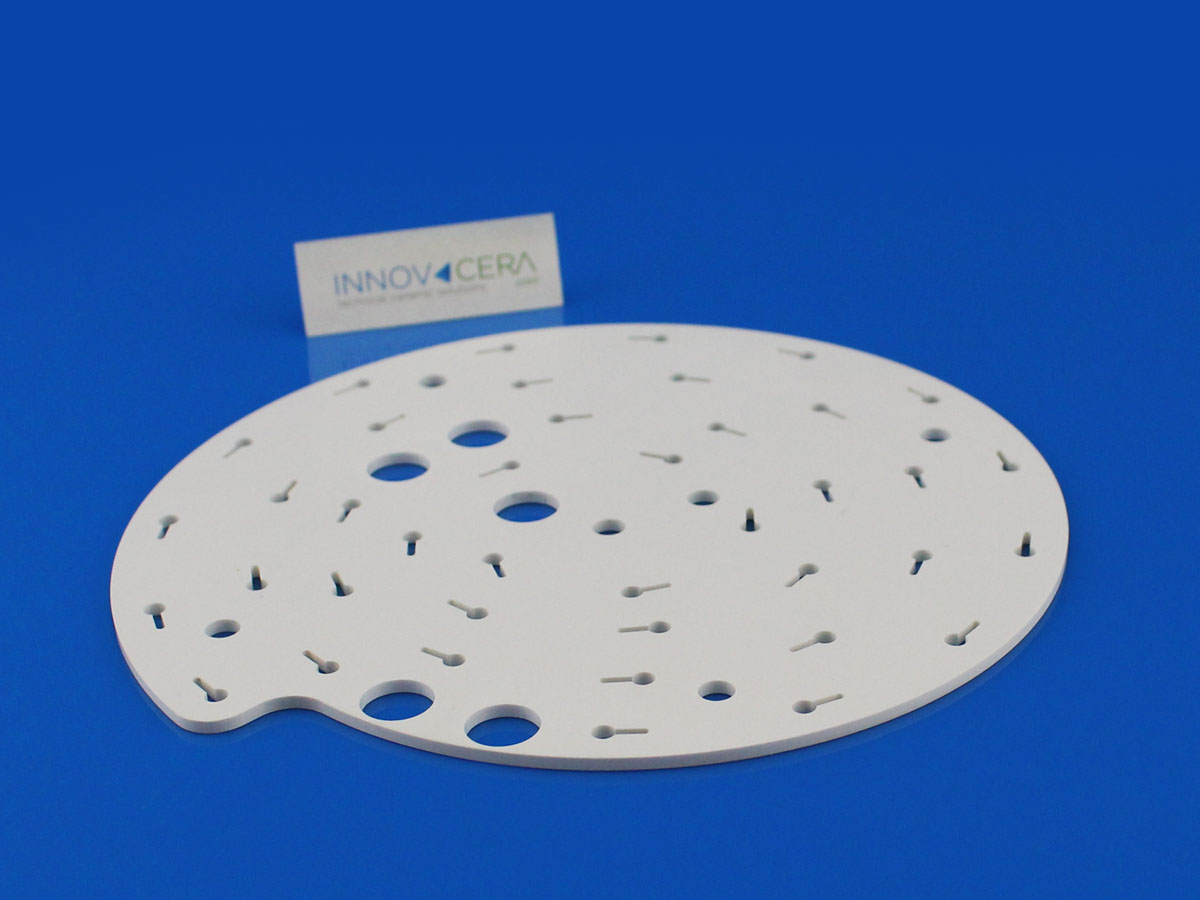

High Temperature Environments

Temperature stability and excellent resistance to thermal shock make BN the ideal material in the toughest high-temperature environments such as equipment for plasma arc welding, diffusion source wafers, and semiconductor crystal growth equipment & processing.

-

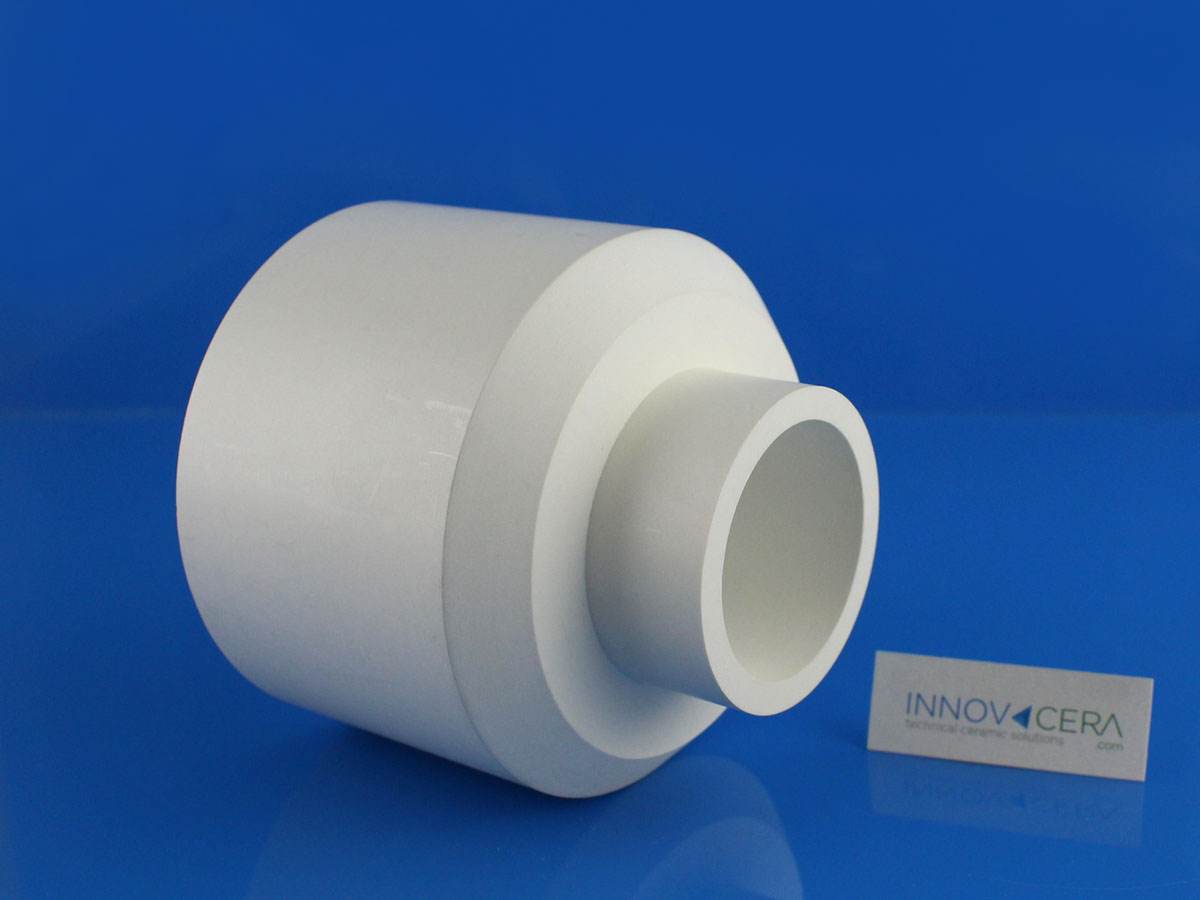

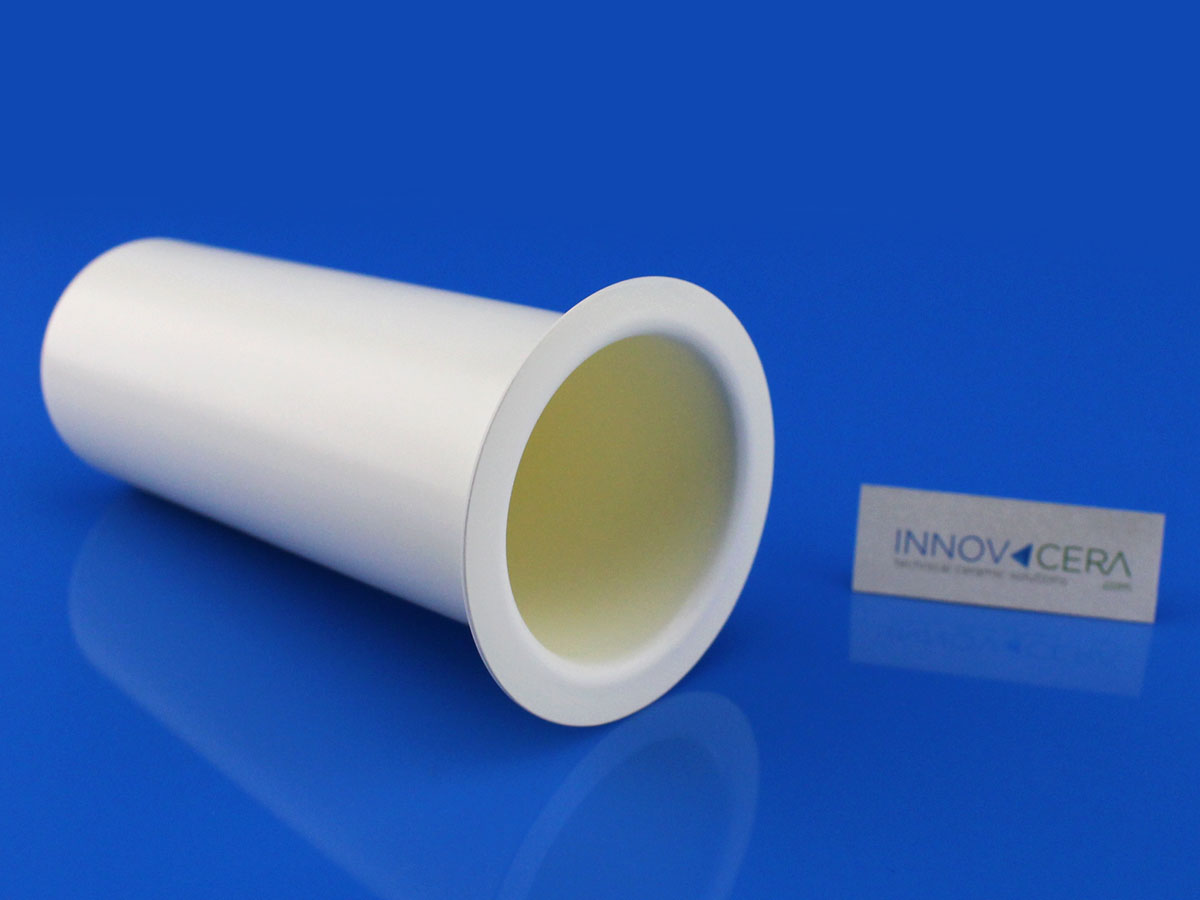

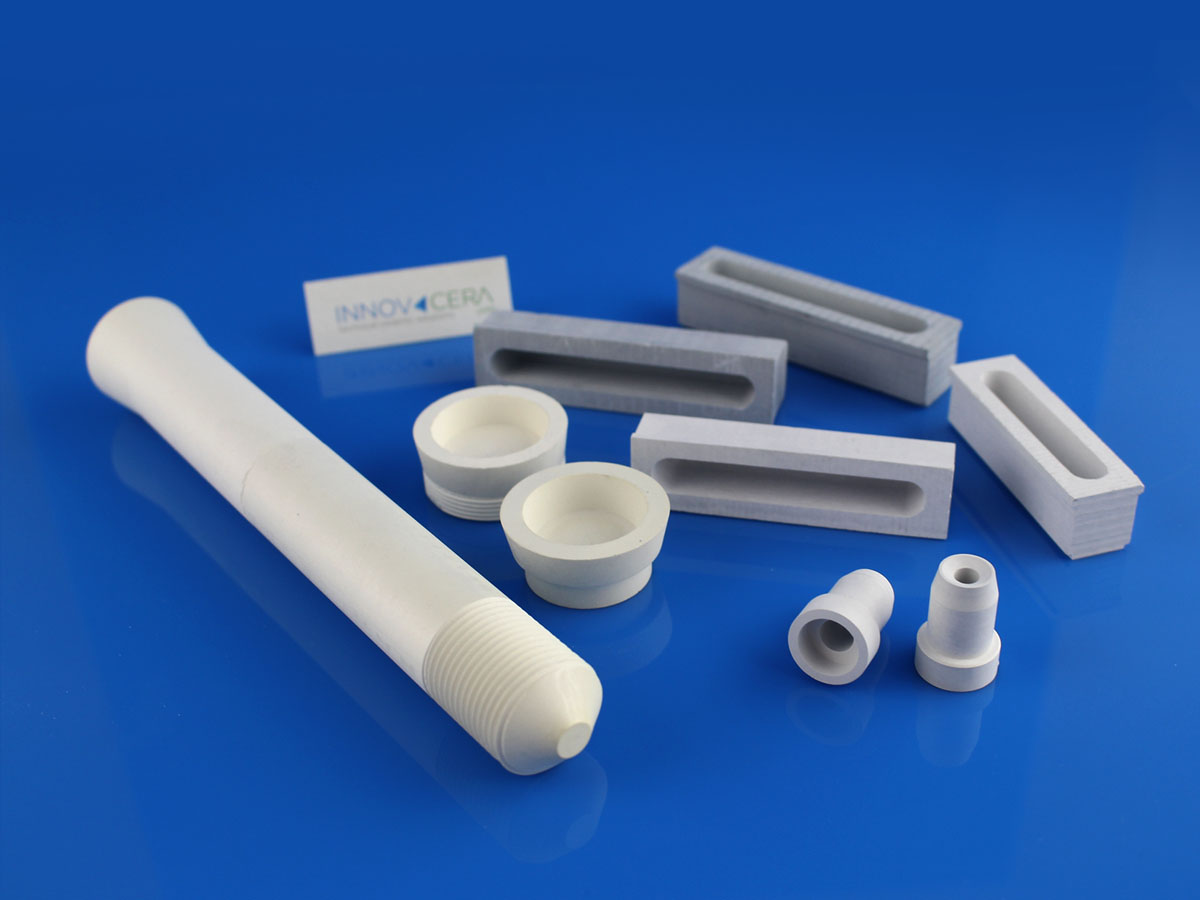

Molten Metal Handling

BN is inorganic, inert, nonreactive with halide salts and reagents, and is not wet by most molten metals and slags. These characteristics, combined with low thermal expansion, make it ideal for interface materials used in various molten metal processes.

Comparison of Boron Nitride Ceramics

| Properties | Units | BMA | BSC | BMZ | BAN |

| Main Composition | – | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+ALN |

| Color | – | White Graphite |

Greyish Green |

White Graphite |

Greyish Green |

| Density | g/cm3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 |

| Three-Point Bending Strength |

MPa | 65 | 80 | 90 | 90 |

| Compressive Strength | MPa | 145 | 175 | 220 | 220 |

| Thermal Conductivity | W/m·k | 35 | 45 | 30 | 85 |

| Thermal Expansion Coefficient (20-1000℃) |

10-6/K | 2 | 2.8 | 3.5 | 2.8 |

| Max Using Temperature In Atmosphere In Inactive Gas In High Vacuum (Long Time) |

(℃) | 900 1750 1750 |

900 1800 1800 |

900 1800 1800 |

900 1750 1750 |

| Room Temperature Electric Resistivity |

Ω·cm | >1013 | >1012 | >1012 | >1013 |

| Typical Application | – | Powder Metallurgy |

Powder Metallurgy |

Metal Casting |

Powder Metallurgy |

| High Temperature Electrical Furnace Components |

– | √ | √ | √ | √ |

| Metal Vaporize Crucible | √ | ||||

| The Container of Metal or Glass Melting |

– | √ | √ | √ | √ |

| The Casting Mould Components of The Precious Metal and Special Alloy. |

– | √ | – | – | √ |

| High Temperature Support Part |

– | √ | – | √ | √ |

| Nozzle and Transport Tube of The Melting Metal |

– | √ | √ | √ | √ |

| Nitrides Sintering (Sagger and Setter Plate) |

– | – | – | – | – |

Remark: The value is just for review, different using conditions will have a little difference.

ENQUIRY

ENQUIRY