In the world of soldering, the tools we use are crucial to achieving precise and efficient results. One key component that contributes significantly to the performance of soldering irons is the heating element. Modern soldering irons often use advanced heating technologies like MCH (Metal Ceramic Heaters.) to ensure quick heat-up times, temperature stability, and energy efficiency. Let’s explore what MCH heaters are and how they enhance soldering iron tools.

What is an MCH Heater?

MCH heaters are a type of ceramic heating element used in various applications, including soldering irons. It refers to a ceramic heating element in which a meta tungsten or molybdenum manganese paste is printed on a ceramic casting body and laminated by hot pressing and then co-fired at 1600°C, in a hydrogen atmosphere to co-sinter ceramic and metal. This ceramic composition allows MCH heaters to exhibit exceptional thermal properties and durability.

The key advantage of MCH heaters lies in their rapid response to changes in electrical input, enabling precise control over the temperature of the soldering iron tip. Unlike traditional heating elements such as copper or nickel-based coils, MCH heaters distribute heat more uniformly and efficiently, resulting in improved thermal conductivity and energy conservation.

Benefits of MCH Heaters for Soldering Irons

Fast Heat-Up Time: MCH heaters heat up quickly due to their low thermal mass, reducing the wait time before you can start soldering.

Temperature Stability: These heaters offer excellent temperature control and stability, maintaining consistent heat levels even during prolonged use.

Energy Efficiency: MCH heaters are highly efficient in converting electrical energy into heat, minimizing energy wastage, and reducing operational costs.

Uniform Heating: The uniform heat distribution across the ceramic surface ensures that the soldering tip reaches and maintains the desired temperature evenly.

Compact Design: MCH heaters are compact and lightweight, contributing to the overall ergonomic design of modern soldering irons.

How MCH Heaters Work in Soldering Iron Tools

In a soldering iron equipped with an MCH heater, electrical current flows through the ceramic heating element. The ceramic material rapidly heats up and transfers this heat to the soldering tip, typically made of copper or another conductive material. The MCH heater’s efficient heat transfer mechanism ensures that the soldering tip reaches the desired temperature swiftly and maintains it consistently.

The temperature of the MCH heater can be controlled using a thermostat or electronic control system integrated into the soldering iron. This allows users to set precise temperature levels suitable for different soldering tasks, from delicate electronics work to heavy-duty soldering jobs.

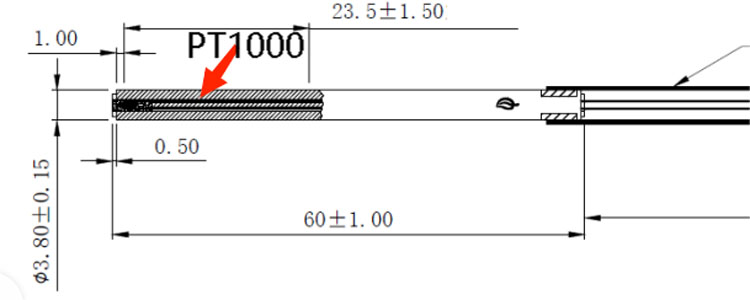

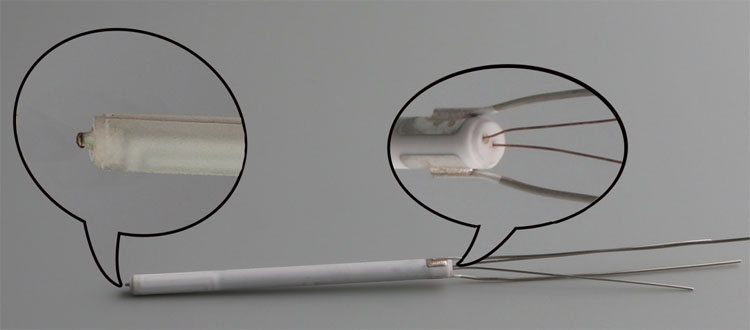

A PT1000 temperature sensor could also be integrated into the MCH heater to help test the temperature and make the design more compact. See below the drawing and picture of the heater.

Conclusion

MCH heaters have revolutionized the performance of soldering irons by offering rapid heating, precise temperature control, and energy efficiency. These advanced heating elements enable soldering professionals and hobbyists to work more accurately and effectively. As technology continues to evolve, we can expect further enhancements in soldering tools driven by innovations in heating technologies like MCH.

If you have any questions about the MCH heater, welcome to contact us at sales@innovacera.com.

お問い合わせ

お問い合わせ