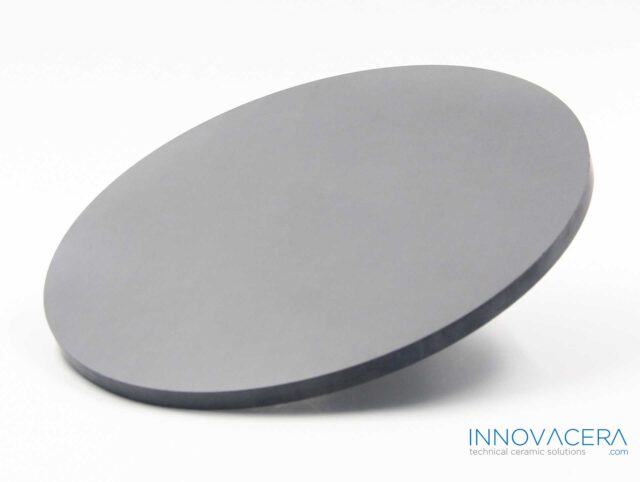

Technical ceramics are favored in a wide range of electronics and engineering applications for their chemical and mechanical properties. Compared to metals, they are stronger in compression, especially at higher temperatures. Ceramics have a good thermal stability (i.e. a low coefficient of thermal expansion) and good thermal and electrical resistance. They are also hard, and have excellent dimensional stability.

As a result, the list of applications for technical ceramics is long and varied, including, for example: aerospace engine blades, rings and valve components, industrial pump bearings, cutting tools and die parts, medical instruments, and wide uses in the electronics industry as a substrate and in specialized vacuum components.

Ceramic-Metal Bonding

For many applications it is often necessary to join ceramic to metal to create the finished part.

Ceramic-metal bonding is one of the biggest challenges that has faced manufacturers and users over the years because of the inherent differences in the thermal expansion coefficients of the two types of materials. Various methods are available, including mechanical fasteners, friction welding, and adhesive bonding, but by far the most widely used and effective method for creating a leaktight, robust joint between ceramic and metal is by brazing. This starts with the chemical bonding metallization of the ceramic to create a wettable surface on which braze alloy will flow between the two components during the brazing process.

Ceramic-metal bonding is one of the biggest challenges that has faced manufacturers and users over the years because of the inherent differences in the thermal expansion coefficients of the two types of materials. Various methods are available, including mechanical fasteners, friction welding, and adhesive bonding, but by far the most widely used and effective method for creating a leaktight, robust joint between ceramic and metal is by brazing. This starts with the chemical bonding metallization of the ceramic to create a wettable surface on which braze alloy will flow between the two components during the brazing process.

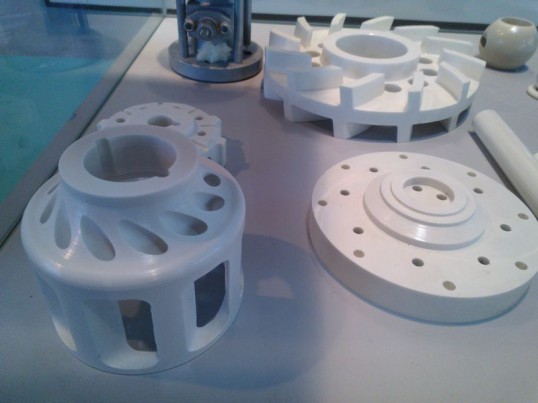

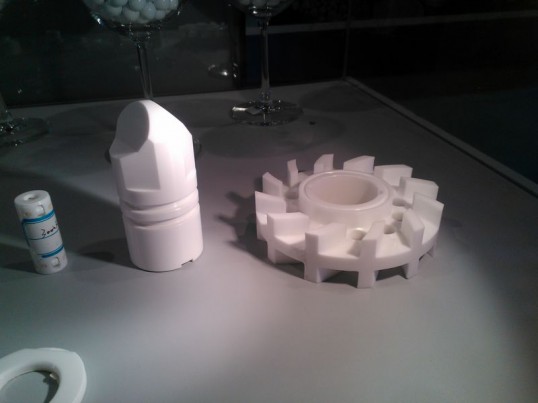

Morgan Advanced Ceramics is a worldwide designer and manufacturer of metallized ceramic components, producing custom parts for applications ranging from very small volume production runs of high-value components for special projects to high-volume manufacture of precision designs. Here are two examples.

Example 1: A Unique Engineering Challenge

ISIS, a world-class spallation neutron source based at the CCLRC Rutherford Appleton Laboratory, Oxfordshire, UK commissioned a series of highly specialized metallized ceramic components from Morgan Advanced Ceramics as part of a major expansion project to build a Second Target Station (TS-2).

The components are a fundamental part of instrumentation, monitoring the intensity of the extracted proton beam (EPB). Ceramic vacuum tubes used in the first target station were sealed with Indium wire, but experience proved that these became unreliable if disturbed. Metallized ceramic offered a solution that provides a 100% reliable vacuum seal within the very tight tolerances of the design

There were two key challenges: first, to come up with a design and a manufacturing process that would produce a robust, high integrity vacuum seal (leak rate 10-8mbar l/s) across a large component (200 mm diameter); second, to solve the problem of the differences in thermal coefficient between the alumina ceramics of the tube and its mild steel flanges. A very tight specification was set for the physical dimensions and cleanliness of the components because of the nature of the project.

The ISIS assembly is 158 mm long with two nickel-plated mild steel flanges 240 mm in diameter, insulated from each other by a preformed diamond ground alumina ceramic insulator. To ensure hermetic integrity of the assembly, the ceramic is brazed in a hydrogen/nitrogen furnace at 850°C to two flanges made of nickel iron cobalt steel, chosen because it provides the best thermal expansion match to the ceramic. This process is achieved by applying a moly-manganese coating, which is sintered at 1,400°C, then electroplating a layer of nickel. The ceramic/metal-brazed subassembly is then welded to the mild steel flanges with a stainless steel interface and machined to the final dimensions.

The ISIS assembly is 158 mm long with two nickel-plated mild steel flanges 240 mm in diameter, insulated from each other by a preformed diamond ground alumina ceramic insulator. To ensure hermetic integrity of the assembly, the ceramic is brazed in a hydrogen/nitrogen furnace at 850°C to two flanges made of nickel iron cobalt steel, chosen because it provides the best thermal expansion match to the ceramic. This process is achieved by applying a moly-manganese coating, which is sintered at 1,400°C, then electroplating a layer of nickel. The ceramic/metal-brazed subassembly is then welded to the mild steel flanges with a stainless steel interface and machined to the final dimensions.

The order from ISIS was for 13 components, supplied by the end of 2006. As is usually the case with this sort of project, neither time nor budget was available to produce a prototype to refine the process, so the experience and expertise of the specialist team were relied on to get it right first time. Problems were solved as they arose and all the components were delivered.

Example 2: Precision and Consistency

For another customer, Morgan Advanced Ceramics manufacturers metallized ceramic components forvacuum electronic devices used in continuous wave and pulsed radar systems, such as those for fighter aircraft.

Here the challenge is to push the performance envelope of the materials to meet the industry’s demand for higher frequencies. This means smaller components with the same physical properties as their larger cousins, and calls for very high precision engineering and close quality control to ensure consistency throughout production.

For example, the smallest part made in this way is a cylinder with an internal diameter of just 0.2 in. The internal surface is metallized to a very tight thickness tolerance, within 0.007-0.0012 in. The metallization process used is based on molybdenum-manganese (MoMn) refractory ink systems developed in-house by Morgan Advanced Ceramics and is matched to specific high purity alumina ceramic bodies to ensure consistent high strength bonds. The glass phases in the MoMn metallization bond with the glass phases in the ceramic to form the bond. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Conclusion

Advanced ceramics are meeting the needs for higher performance critical components in a wide variety of applications. Through a detailed understanding of ceramic-metal bonding techniques, such as the metallization process, designers and manufacturers are better able to devise these key components.

Ceramic-metal bonding is one of the biggest challenges that has faced manufacturers and users over the years because of the inherent differences in the thermal expansion coefficients of the two types of materials. Various methods are available, including mechanical fasteners, friction welding, and adhesive bonding, but by far the most widely used and effective method for creating a leaktight, robust joint between ceramic and metal is by brazing. This starts with the chemical bonding metallization of the ceramic to create a wettable surface on which braze alloy will flow between the two components during the brazing process.

Ceramic-metal bonding is one of the biggest challenges that has faced manufacturers and users over the years because of the inherent differences in the thermal expansion coefficients of the two types of materials. Various methods are available, including mechanical fasteners, friction welding, and adhesive bonding, but by far the most widely used and effective method for creating a leaktight, robust joint between ceramic and metal is by brazing. This starts with the chemical bonding metallization of the ceramic to create a wettable surface on which braze alloy will flow between the two components during the brazing process. The ISIS assembly is 158 mm long with two nickel-plated mild steel flanges 240 mm in diameter, insulated from each other by a preformed diamond ground alumina ceramic insulator. To ensure hermetic integrity of the assembly, the ceramic is brazed in a hydrogen/nitrogen furnace at 850

The ISIS assembly is 158 mm long with two nickel-plated mild steel flanges 240 mm in diameter, insulated from each other by a preformed diamond ground alumina ceramic insulator. To ensure hermetic integrity of the assembly, the ceramic is brazed in a hydrogen/nitrogen furnace at 850

お問い合わせ

お問い合わせ