Aluminum Nitride (AlN) Ceramics exhibit exceptional characteristics as below:

- Good mechanical properties,

- Higher flexural strength than Al2O3 and BeO ceramics,

- High temperature and corrosion resistance.

- High thermal conductivity combined with good electrical insulation characteristics.

- Exceptional stability when exposed to many molten salts.

- Thermal stability up to at least 1500°C

- Favorable mechanical characteristics extending into the high temperature range.

- Low thermal expansion and resistance to thermal shock.

- Special optical and acoustic characteristics.

Aluminum Nitride Ceramic Physical Properties:

| Properties | Value |

| Color | Dark Gray |

| Main Content | 96%ALN |

| Bulk Density(g/cm3) | 3.335 |

| Water Absorption | 0.00 |

| Flexural Strength(MPa) | 382.70 |

| Dielectric Constant(1MHz) | 8.56 |

| Coefficient Linear Thermal Expansion(/℃,5℃/min, 20-300℃) | 2.805*10-6 |

| Thermal Conductivity(30 degree Celsius) | >=170 |

| Chemical Durability(mg/cm2) | 0.97 |

| Thermal Shocking Resistance | No cracks |

| Volume Resistivity(Ω.cm) (20 degree Celsius) | 1.4*1014 |

| Dielectric Strength(KV/mm) | 18.45 |

| Surface roughness Ra(μm) | 0.3-0.5 |

| Camber(length ‰) | <=2‰ |

Forming Processing:

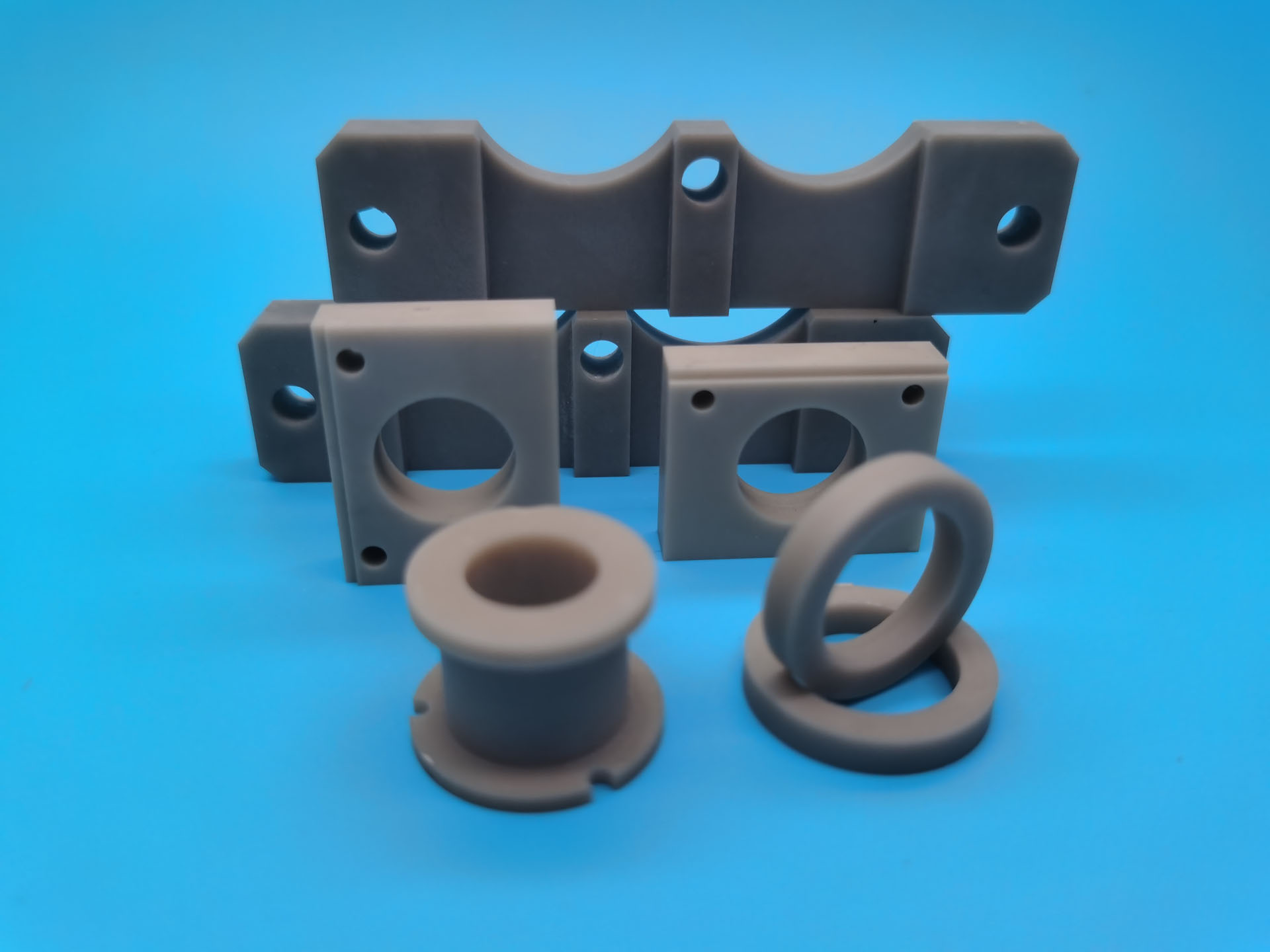

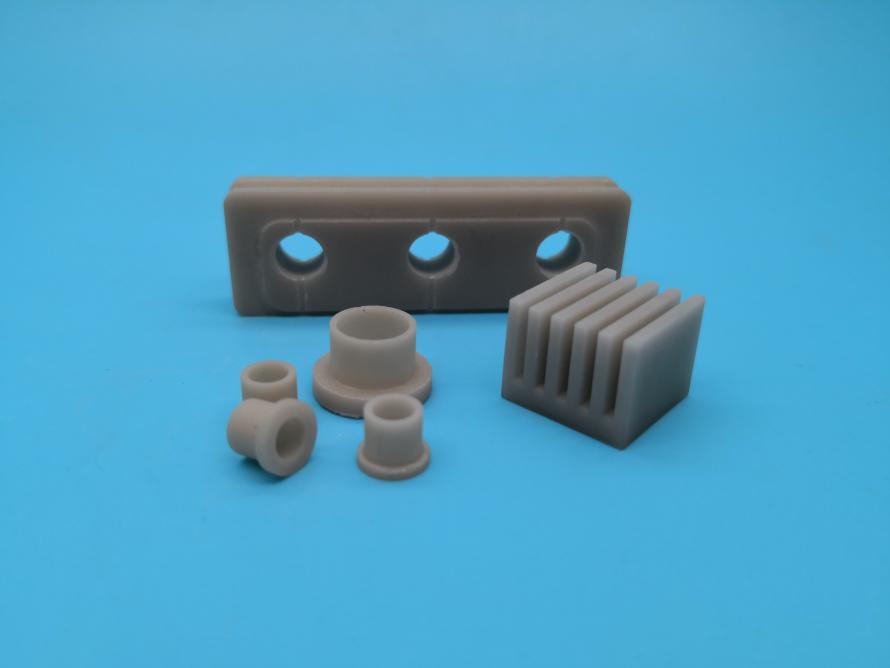

- Ceramic Injection Molding

- Low Pressure Injection Molding

- Cold Isostatic Press

- Dry Press

- Tape Casting

- Precision Machining Processing

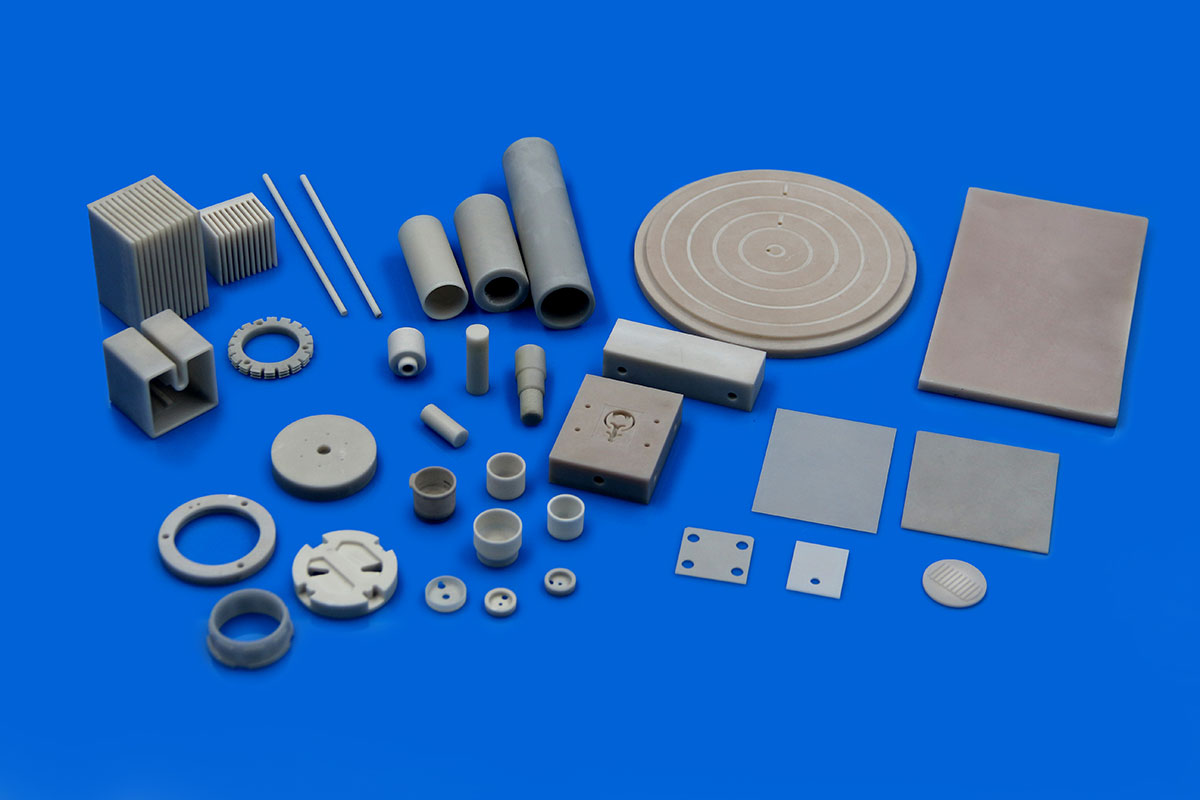

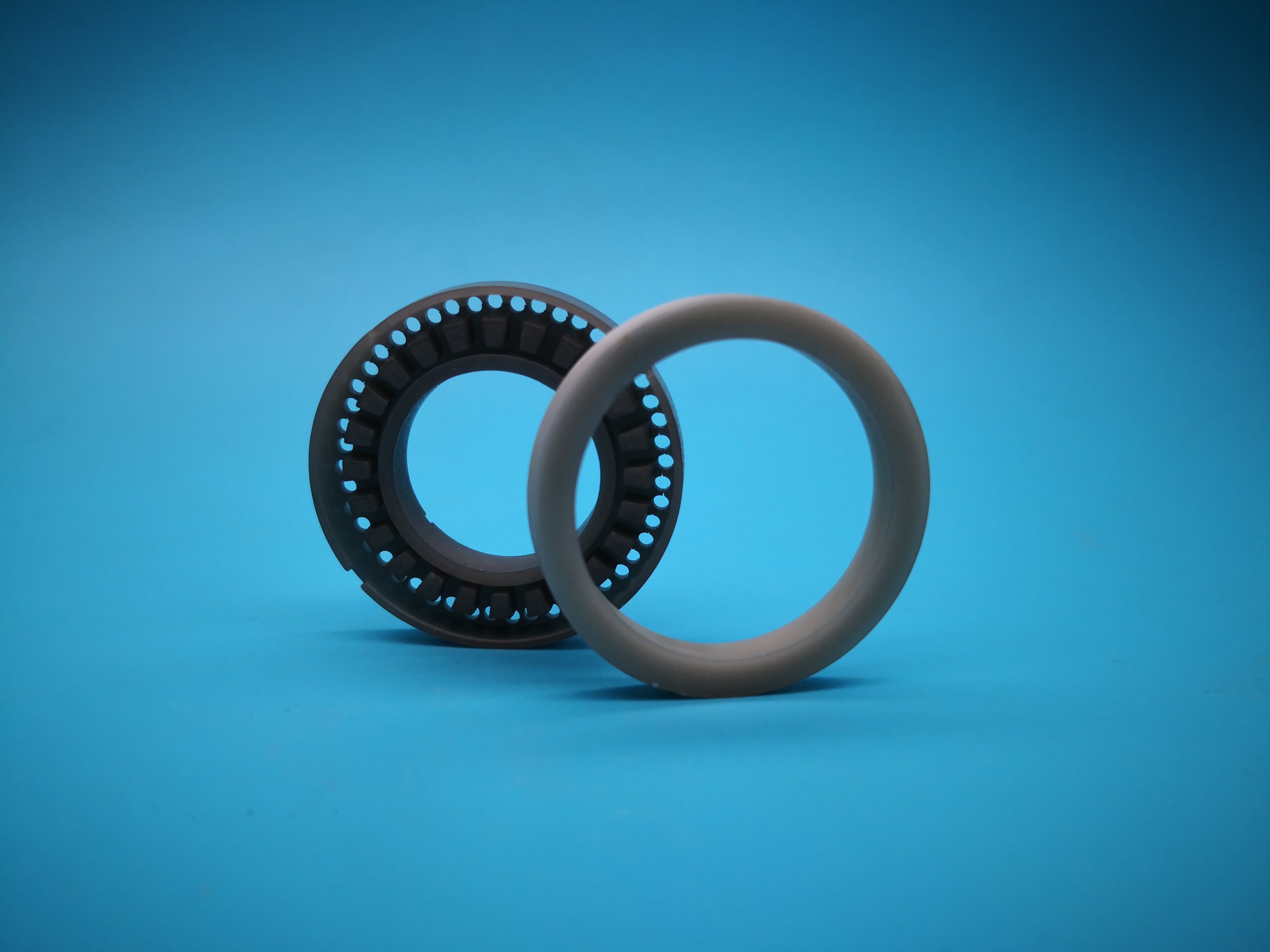

Aluminum Nitride Ceramic Products:

- AlN Ceramic Heat-sinks for high power system

- AlN Crucible, Al evaporating dish and other high-temperature corrosion resistant parts.

- Direct Bond Copper Substrates (DBC)

- AlN Ceramic Rod

- ALN Ceramic Wafer

- ALN Ceramic Substrate

- AlN Ceramic Heater

- Custom Shape

Aluminum Nitride Ceramic Components Application:

- Components for semiconductor equipment

- IC packaging

- Thermal module substrate

- High power transistor module substrate

- High frequency device substrate

- Exothermic insulation board for Thyristor Modules

- Semiconductor laser, fixed substrate for light emitting diode (LED)

- Hybrid integrated module, ignition device module

- Used in the sintering of structural ceramics

- AlN Crucible for Metal Melting & Electronic cigarettes

- Applied to luminous materials

- Applied to the substrate material

Aluminum nitride (AlN) has a maximum direct bandgap width of 6.2eV, which has a higher photoelectric conversion efficiency than an indirect bandgap semiconductor. As an important blue and ultraviolet luminescent material, AlN is used in ULTRAVIOLET/deep ultraviolet light-emitting diodes, ultraviolet laser diodes, and ultraviolet detectors. In addition, AlN can form continuous solid solutions with group III nitride compounds such as GaN and InN, and its three or four element alloys can achieve continuous tunable band gap from visible band to deep ultraviolet band, making it an important high-performance luminescent material.

AlN crystals are ideal substrates for GaN, AlGaN and AlN epitaxial materials. Compared with sapphire or SiC substrates, AlN has higher thermal matching and chemical compatibility with GaN and lower stress between substrate and epitaxial layer. Therefore, AlN crystal as GaN epitaxial substrate can greatly reduce the defect density in the device, improve the performance of the device, and has a good application prospect in the preparation of high temperature, high frequency, high power electronic devices.

In addition, the substrate of AlGaN epitaxial material with AlN crystal as high Al component can effectively reduce the defect density in the nitride epitaxial layer, and greatly improve the performance and service life of nitride semiconductor devices.

Regular Specification of ALN ceramic substrate:

Length &Width: 25.4mm; 50.8mm; 63.5mm; 76.2mm; 101.6mm; 114.3mm; 127mm; 152.4mm.

Thickness: 0.25mm; 0.5mm; 0.63mm;1mm;1.5mm; 2mm.

Enquiry

Enquiry