Due to the nature of the CVD process, PBN parts generally are requested a wall thickness not more than 3mm. PBN is also a good choice for the extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process gives this pyrolytic boron nitride an almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing.

Pyrolytic Boron Nitride Ceramics Applications:

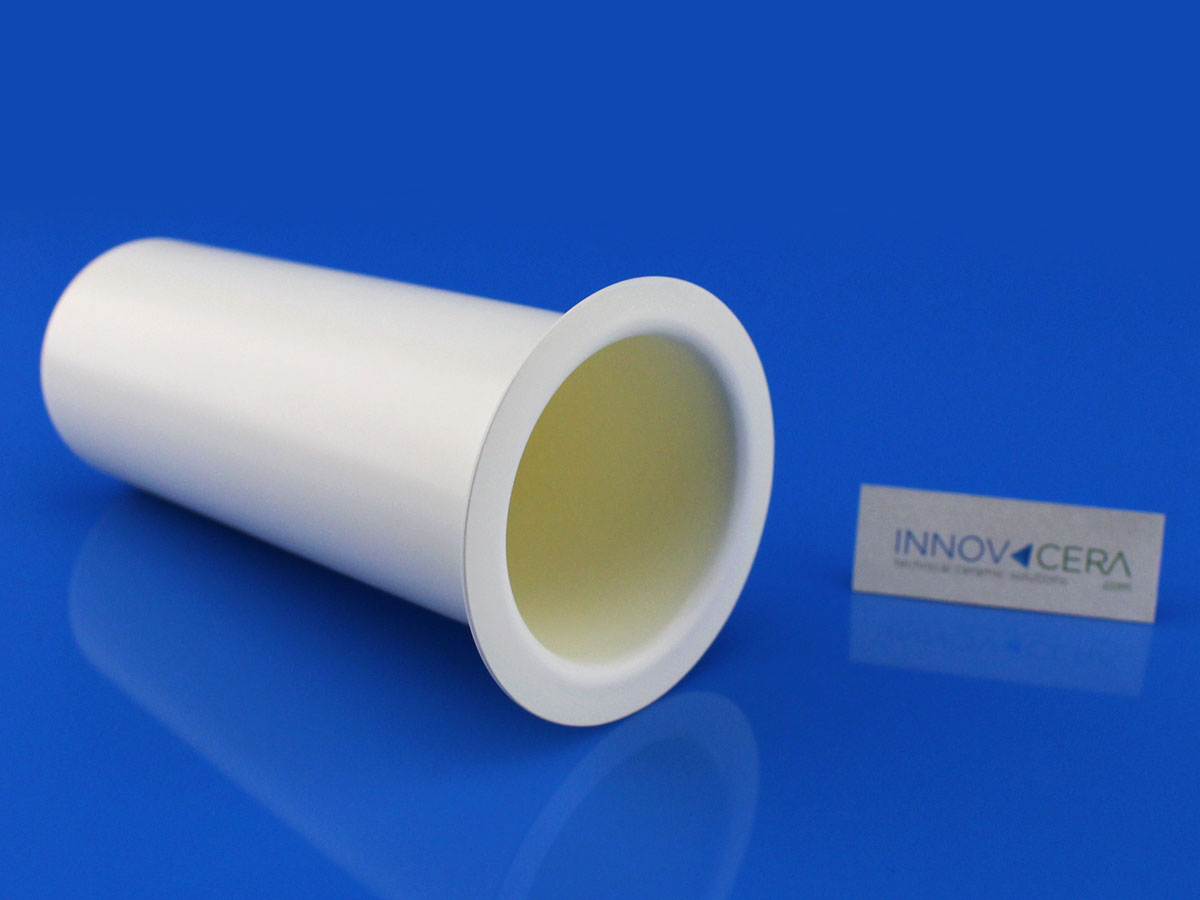

- Crystal growth (VGF, LEC Crucible)

- Molecular Beam Epitaxy(MBE) Crucible

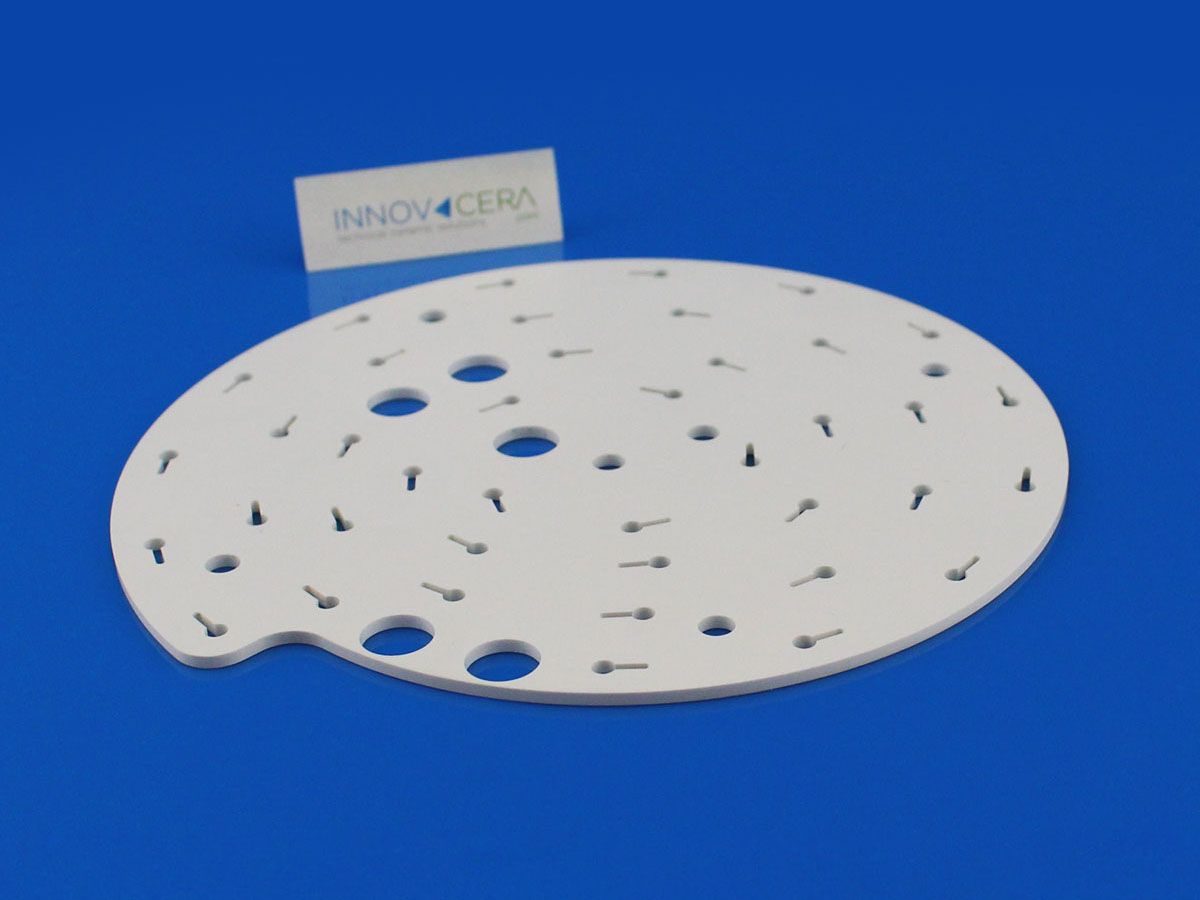

- MOCVD Heater

- PBN Infrared Window

- Traveling Wave Tube (TWT) (PBN Support Rod)

- PBN Coating Graphite

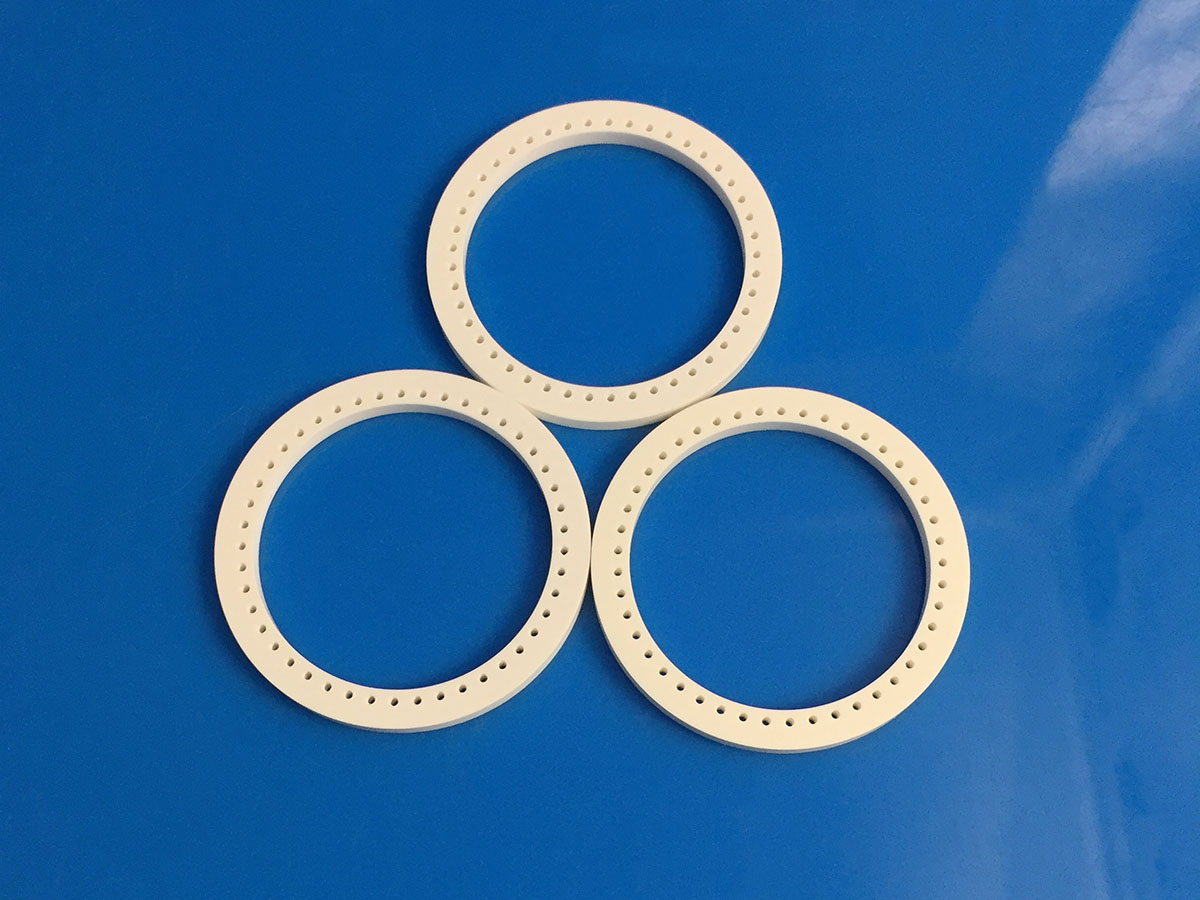

- High temperature, vacuum equipment insulator

Pyrolytic Boron Nitride Ceramics Characteristic:

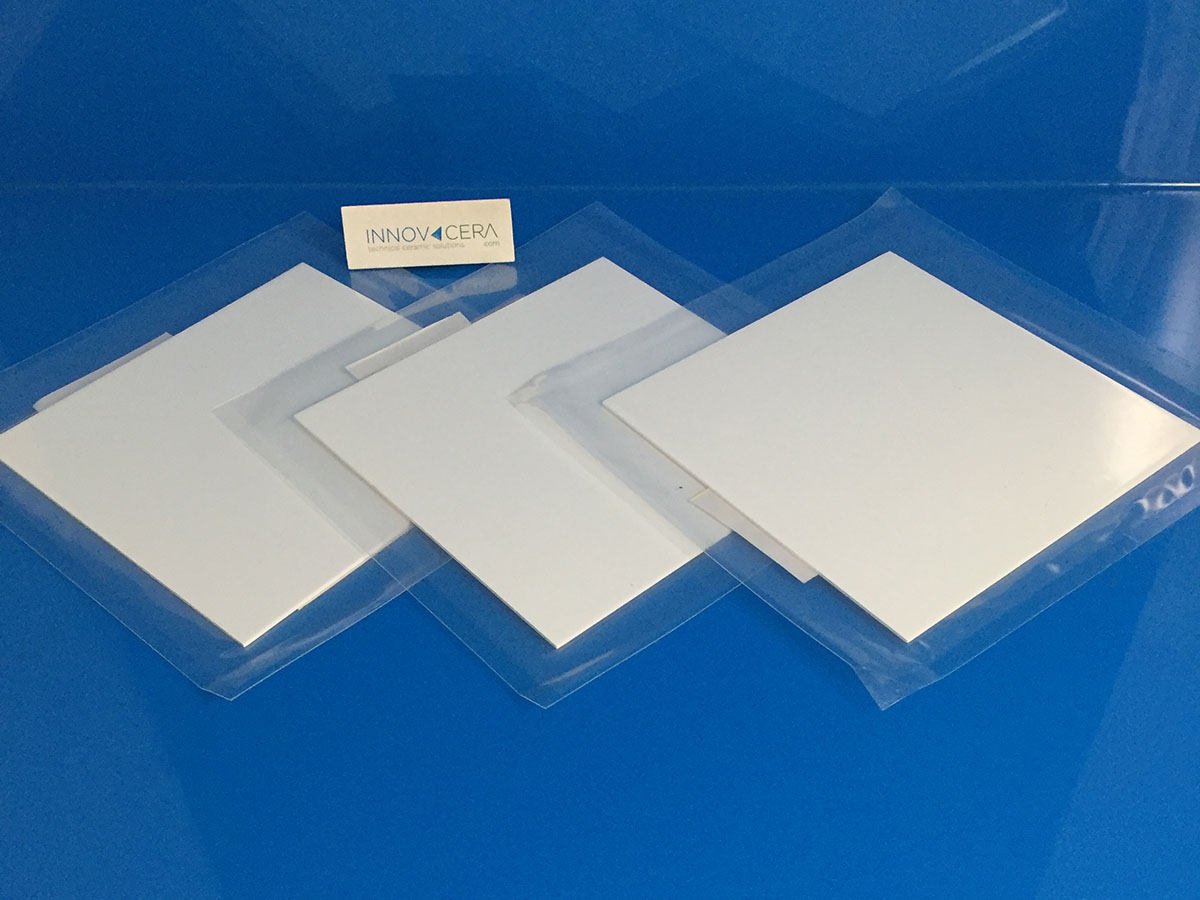

- The color of PBN is ivory and orange-brown, nontoxic, imporosity, easy processing.

- The purity is up to 99.99%, surface densification, good gas barrier properties.

- The strength increases as the temperature rises and peaked at 2200°C.

- Acid, alkali, salt, and organic reagent resistance. Meanwhile, it does not react with the majority of molten metal and semiconductor material.

- Excellent thermal shock resistance, excellent thermal conductivity, low thermal expansion coefficient.

- High resistance, high dielectric strength, low dielectric constant, low dissipation factor, excellent microwave, and infrared ray ability.

- It’s with anisotropy in the mechanics, heat, and electricity.

Pyrolytic Boron Nitride Ceramics Properties:

| Property | Unit | Value | |

| Lattice constant | μm | a: 2.504 x 10^-10 c: 6.692 x 10^-10 | |

| Density | g/cm3 | 2.10-2.15 (PBN Crucible); 2.15-2.19 (PBN Plates) | |

| Micro hardness (Knoop)(ab side) | N/mm2 | 691.88 | |

| Resistivity | Ω*cm | 3.11 x 10^11 | |

| Tensile strength | N/mm2 | 153.86 | |

| Bending strength | ⊥C | N/mm2 | 243.63 |

| ⊥C | N/mm2 | 197.76 | |

| Elastic modulus | N/mm2 | 235690 | |

| Thermal conductivity | W/m*k | “a” direction “c” direction | |

| 200°C | W/m*k | 60 2.60 | |

| 900°C | W/m*k | 43.7 2.8 | |

| Dielectric strength (at room temperature) | KV/mm | 56 | |

Enquiry

Enquiry