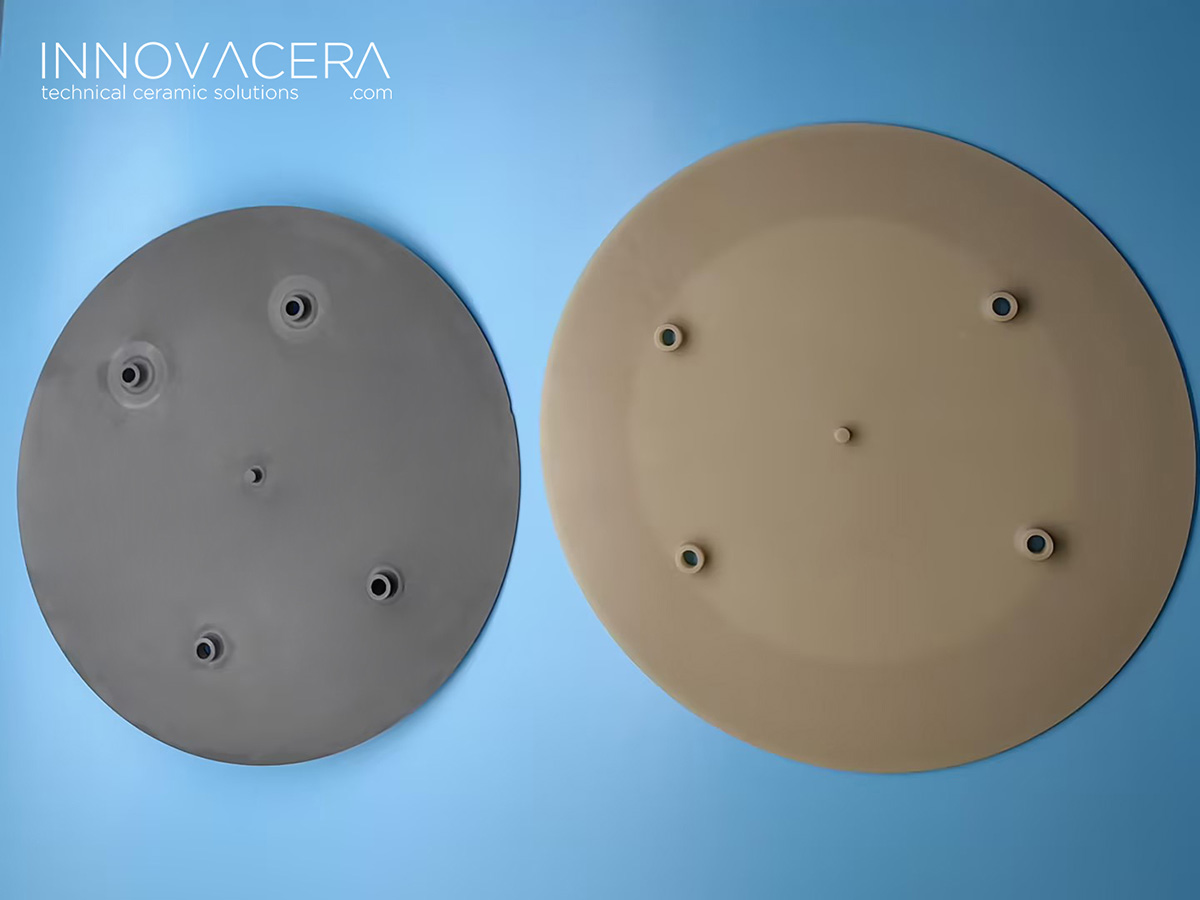

Innovacera Hot pressed ALN ceramic components purity is 99.5% aluminum nitride and its density is about 3.3g/cm3. The thermal conductivity is 140-170 W/(m·k). The forming way of hot-pressed aluminum nitride ceramics is vacuum hot pressing sintering.

After high temperature and high pressure, hot pressed ALN ceramic part mechanical strength and hardness are better than the tap-casting molding process and cold isostatic press method.

Innovacera can provide the maximum size of hot-pressed aluminum nitride ceramic part is Length 500 x width 500 x height < 350 mm and Outer diameter 500 x height < 500 mm

Hot- Pressed aluminum nitride ceramics material properties:

| ITEM | UNIT | Testing Value |

| Hardness | Kgf/mm2 | 1070 |

| Density | G/cm3 | 3.3 |

| Fracture Toughness | Mpa.mg | 2.4 |

| Thermal Conductivity | W/m.k | 140 |

| Flexural Strength | Mpa | 440 |

| Characteristic Strength | Mpa | 450 |

| Coefficient Of Thermal Expansion | X10-6/°C | 5 |

| Dielectric Constant @1MHZ | 9 | |

| Loss Tangent@1MHZ | 0.00029 |

Hot- Pressed aluminum nitride ceramic components features:

- Excellent thermal conductivity

- High electrical insulation

- High dielectric strength

- Resist high temperature and corrosion

- Thermal expansion coefficient similar to Si, GaN, and GaAs semiconductors

- Suit for rigorous or abrasive environments

- Can’t be eroded by all kinds of molten metals and molten hydrochloric acid.

Hot- Pressed aluminum nitride ceramic part application:

- Semiconductor heaters

- Magnetic resonance imaging equipment

- Etching machine

- Integrated circuit part

- Structural packaging materials

- High-power heat dissipation insulating substrates

- Microwave window materials

- Compound semiconductor single crystal growth crucible

Innovacera can provide Hot Pressed Aluminum Nitride (HPALN) as customized size and welcome to send your inquiry for us.

Enquiry

Enquiry