![]()

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials.

When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground.

Applications for silicon nitride include:

- Foundries

- Electronics

- Oil & Gas

- Automotive

- Aerospace

High precision silicon nitride ceramic balls, roller for bearing, pump valve:

High precision silicon nitride ceramic balls, roller for bearing, pump valve

INNOVACERA silicon nitride is processed by gas pressure sintering, which results in a fully dense and nonporous microstructure of interlocking needle-shaped grains. This, combined with the natural toughness of silicon nitride, provides outstanding contact fatigue resistance and mechanical reliability.

Thermocouple Protection Sheaths

Thermocouple Protection Sheaths

INNOVACERA manufactures a range of silicon nitride ceramic and advanced ceramic thermocouple protection sheaths for use in the aluminium and molten metal handling industries. They are an advanced ceramic tube offering outstanding performance for temperature control in aluminium foundries and smelters and are extremely cost effective compared to competitive materials, such as cast iron, silicon carbide and alumina.

Silicon Nitride Ceramic Weld Location Pins

Silicon Nitride Ceramic Weld Location Pins

Ceramic welding pins made of silicon nitride significantly increase service life and enable high levels of precision and greater accuracy over extended periods in projection welding. Metal welding pins often need to be replaced several times a day due to wear and adhering slag, whereas centring pins made of silicon nitride ceramic only need to be replaced about once a month.

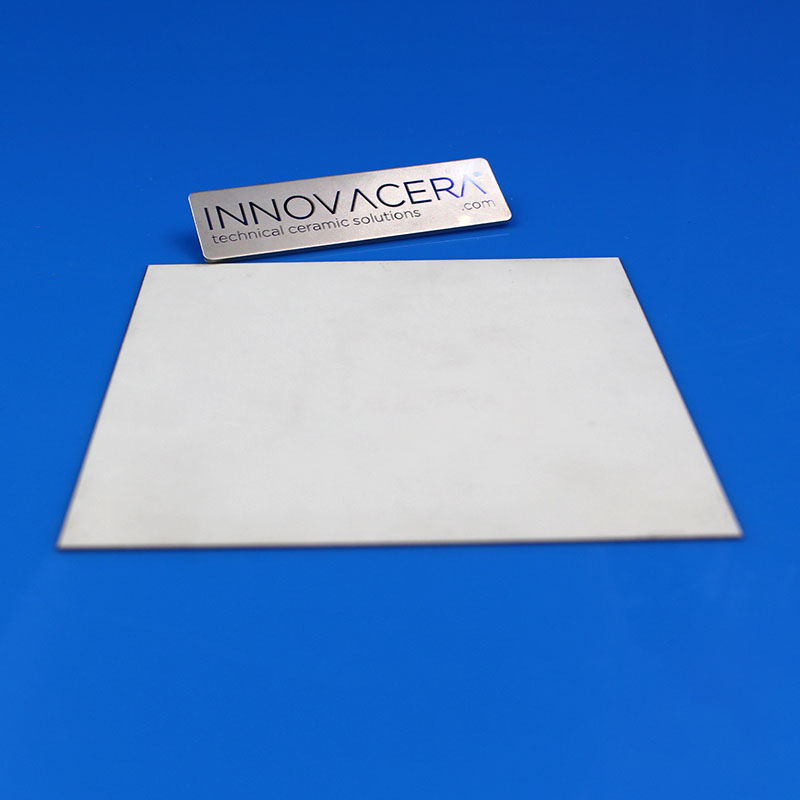

Silicon Nitride Ceramic Substrate for Electronics

Silicon Nitride Ceramic Substrate

INNOVACERA Silicon Nitride substrates, with a thermal conductivity rating of 90 Watts/meter Kelvin, at first glance, appear inferior to Aluminum Nitride grades from the standpoint of heat dissipation. However, Silicon Nitride substrates, due to their far superior mechanical properties, can provide thermal resistance levels comparable to Aluminum Nitride.

Silicon nitride ceramic electric heating element

Silicon Nitride Heater

INNOVACERA’s silicon nitride heating elements are normally rectangular in shape. These heaters have a lot of operation zone up to 1000 degree C and a cold zone in the contact area. The encapsulated terminal can prevent short circuit caused by conductive contamination. They can be operated with or without a controller. Silicon nitride heater has several times the durability that silicon carbide products.

Enquiry

Enquiry