As setter plates, alumina, boron nitride, and aluminum nitride ceramics offer decisive advantages over conventional setters made from materials like graphite or tungsten. This enables energy and cost-efficient processing of high-precision sintering components.

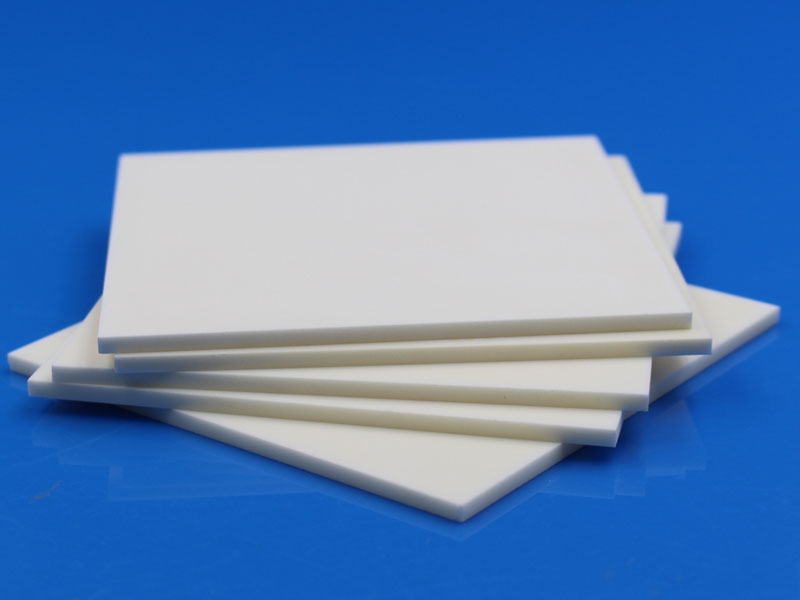

Ceramic sintering tray and setter plates assist optimally in arraying and fixing molded parts in a sintering furnace to prevent brown part deformations during the firing process.

Properties of Ceramic Setter Plate

dust-free and particle-free surface

homogeneous pore size distribution

good mechanical strength with the high porosity

easy machinable, big customized dimensions of the setter possible

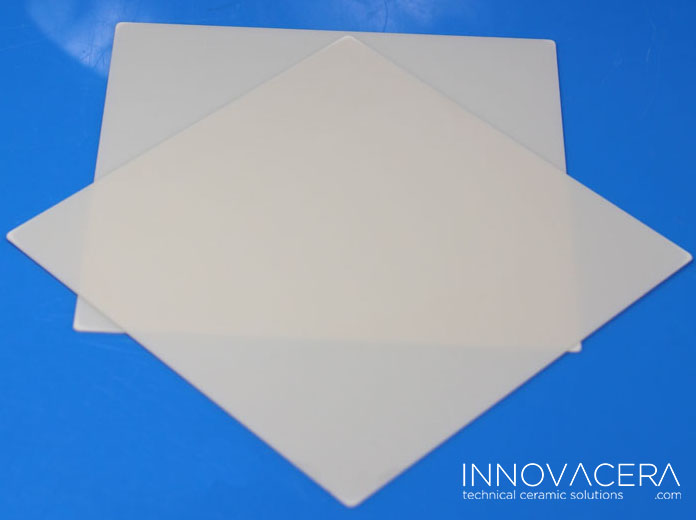

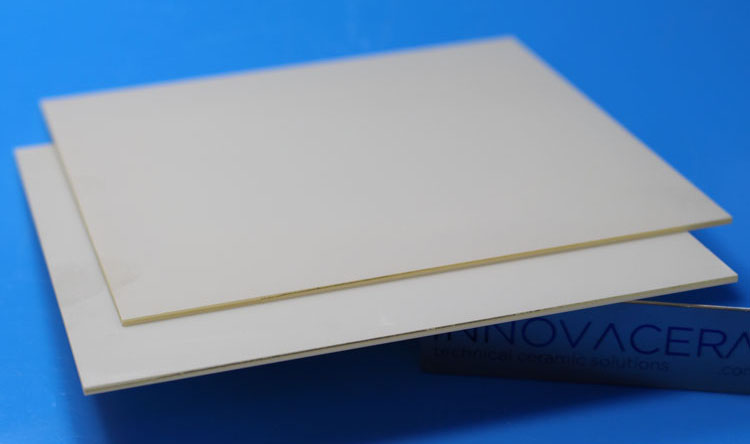

very good planarity and surface quality

homogenous shrinking through unimpeded shrinkage

absorption of the binder into the pores during the debonding process

Aluminum Oxide(Al2O3) ceramic setter plate

Lower cost and it is the most popular ceramic setter plate for Metal Injection Molding, with a max service temperature of up to 1600°C(in air).

Boron Nitride(HBN) ceramic setter plate

Soft like graphite called “white graphite”, medium cost, long service lifetime, and used as a setter plate for sintering high temperatures up to 2100°C(Insert Gas)

Aluminum Nitride (AlN) ceramic setter plate

AlN ceramics is the basis for low lateral temperature differences and results in homogeneous thermal distribution within the sintering components.

| Properties | A-997

Aluminum Oxide |

HBN

Boron Nitride |

AN-170

Aluminum Nitride |

| Color | Ivory | White | Dark Gray |

| Porosity Vol | 0~10% | 25% | 0 |

| Main Content | 99.7% | 99.7% | 95% |

| Bulk Density (g/cm3) | 3.9 | 1.6 | 3.3 |

| Bending Strength (MPa) | 320-340 | 18 | 382.7 |

| Coefficient Linear Thermal Expansion (X10-6/℃) | 7.6 | 1.5 | 2.805 |

| Max Using Temperature (℃) | 1600 | 2100 | 1850 |

The setter plate’s maximum dimensions, such as 350 x 350 mm, enable a high packing density. These setter plates can be stacked with integrated cavities on request thereby ensuring fast, effective sintering furnace charging. This makes optimal use of furnace volume and energy expenditure, which results in a fully energetically optimized sintering process.

Enquiry

Enquiry