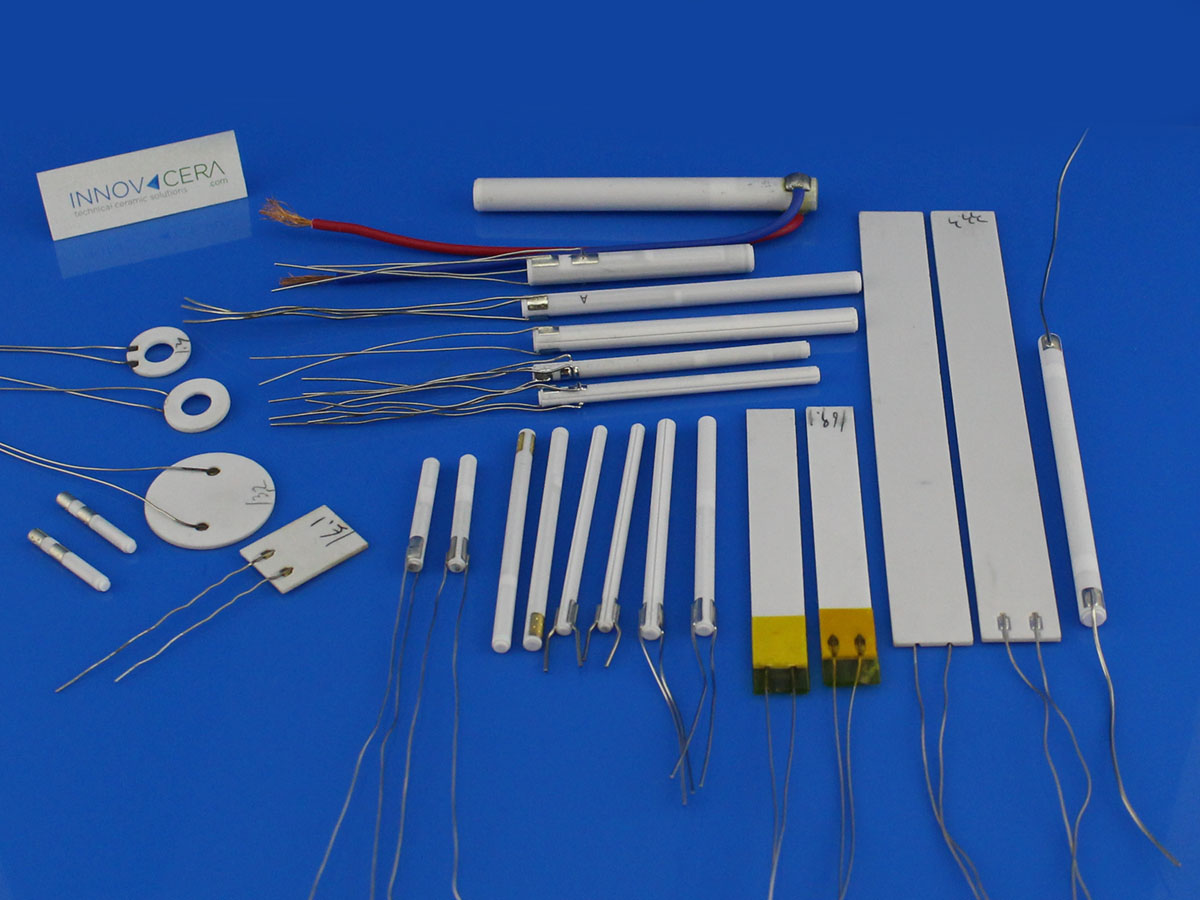

Application of Alumina Ceramic Heaters

-

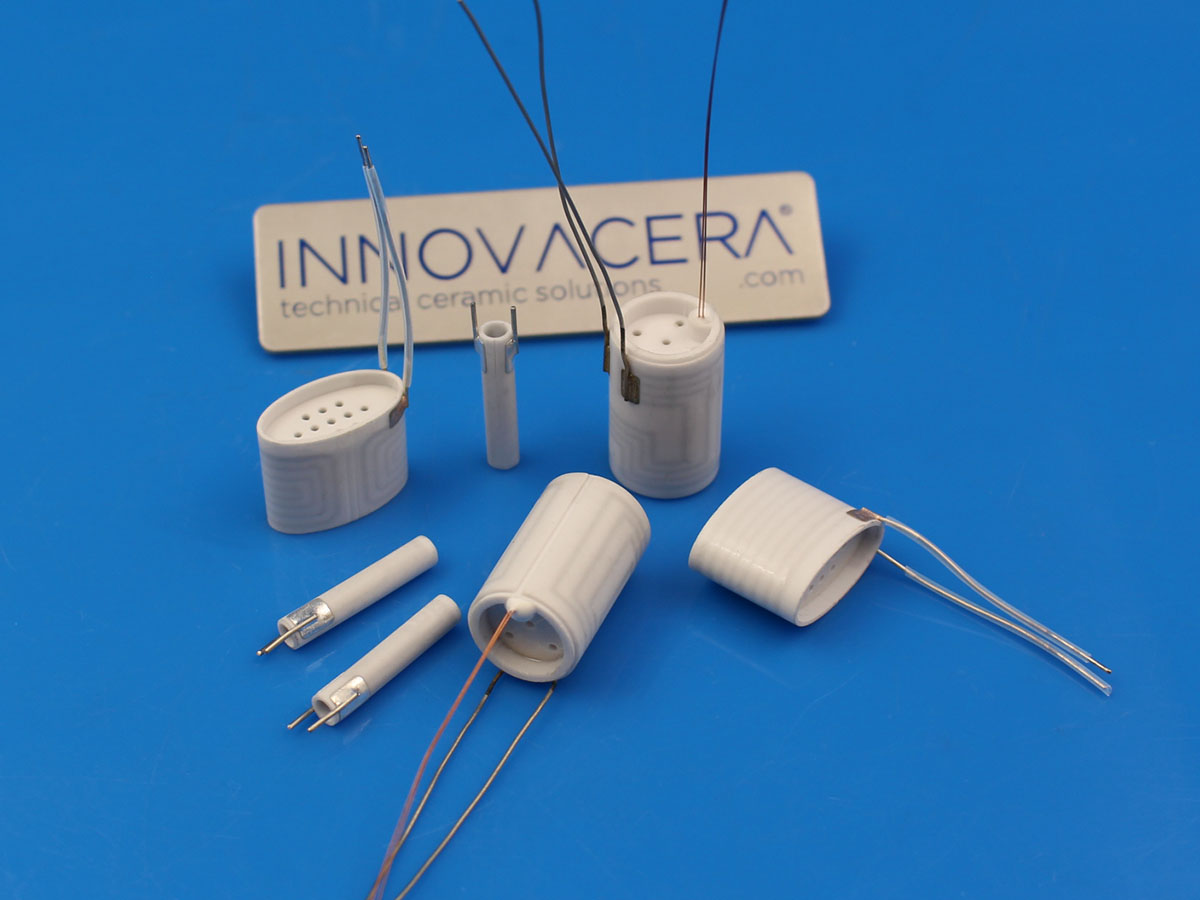

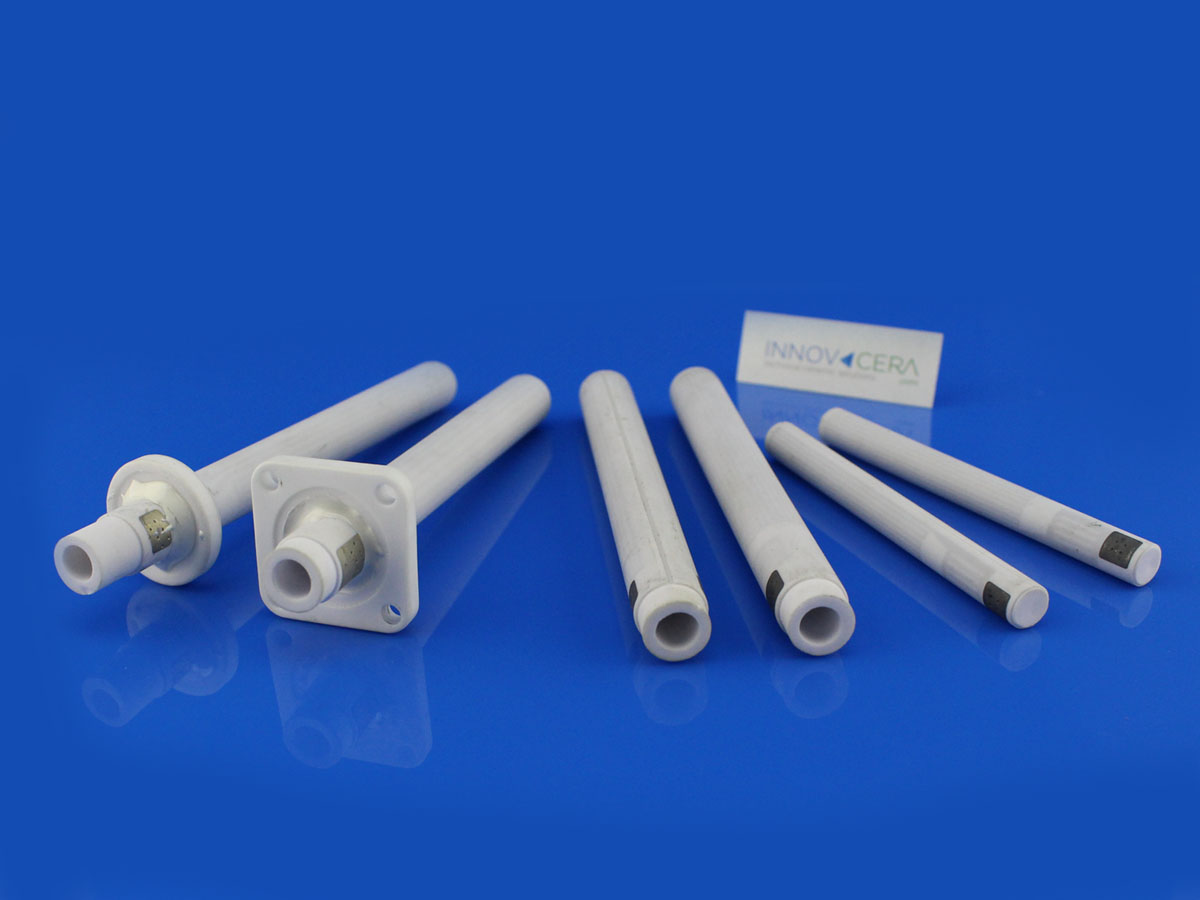

Automotive Components

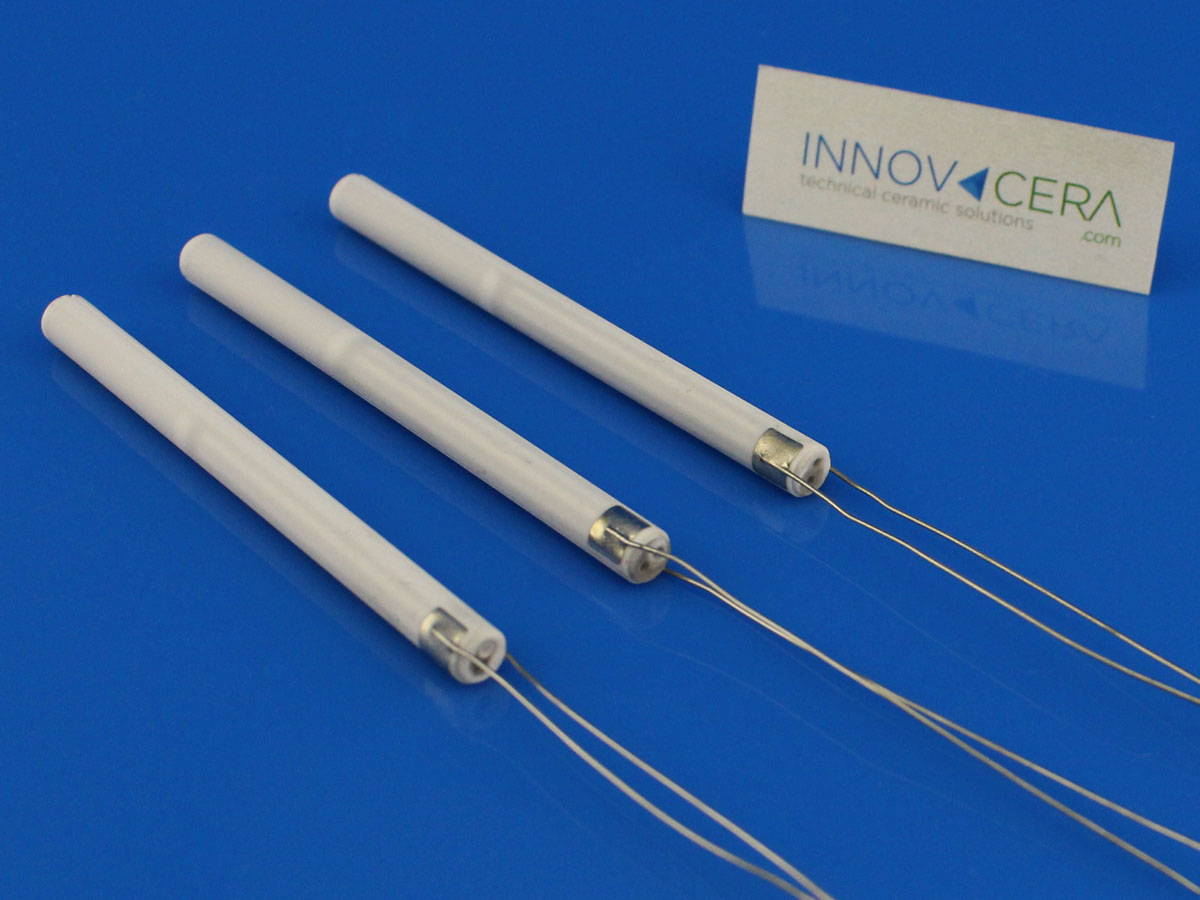

Glow Plug

Igniter for Cabin Heater

Heater for Oxygen Sensor -

Kerosene and Gas Appliances

Igniter

Heater for Vaporizer -

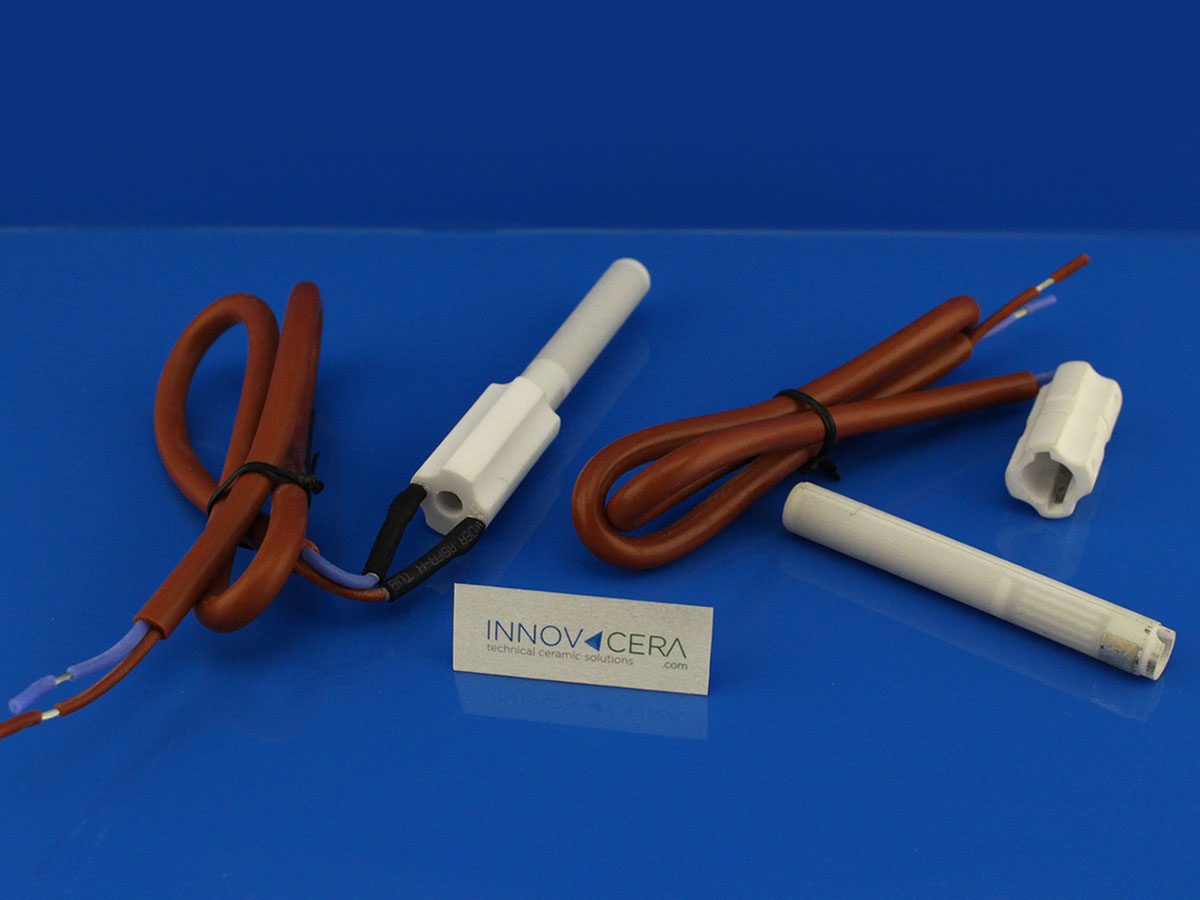

Industrial Heater Applications

Heater for Soldering Iron

Heater for Hair Iron

Bonding Heater

Seal Heater -

Water-Heating Applications

Heater for Toilet Water

Bath Water Heater

Steam Boiler Heater

Liquid Heater for Small Appliances

Advantages of Ceramic Heaters

-

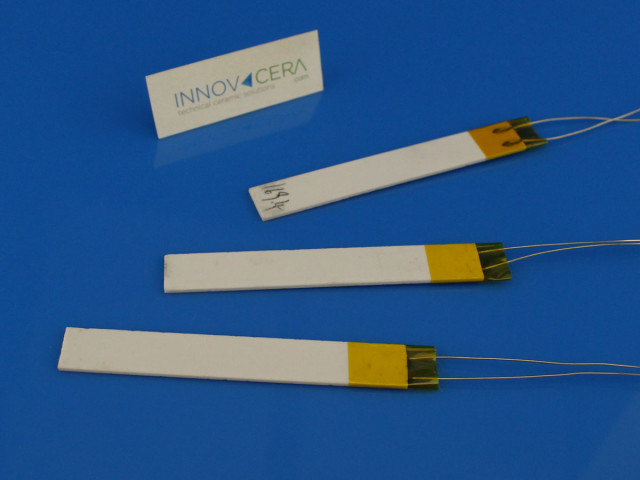

Compact, Lightweight and Energy Efficient

Ceramic heaters feature high watt density and excellent thermal efficiency. Multiple heating elements can be layered into a single unit.

-

Superior Thermal Properties

Ceramic heaters reach high temperatures rapidly and are available with custom-designed heat distribution patterns. The material’s strong insulation properties permit direct contact with a variety of materials, including water, kerosene and metals.

-

High Reliability

Superior dielectric strength, electrical insulation and chemical resistance give Innovacera’s ceramic heaters outstanding reliability. Our oxidation-resistant material ensures a long service life.

-

No Electric Noise

Ceramic heaters produce no electric noise.

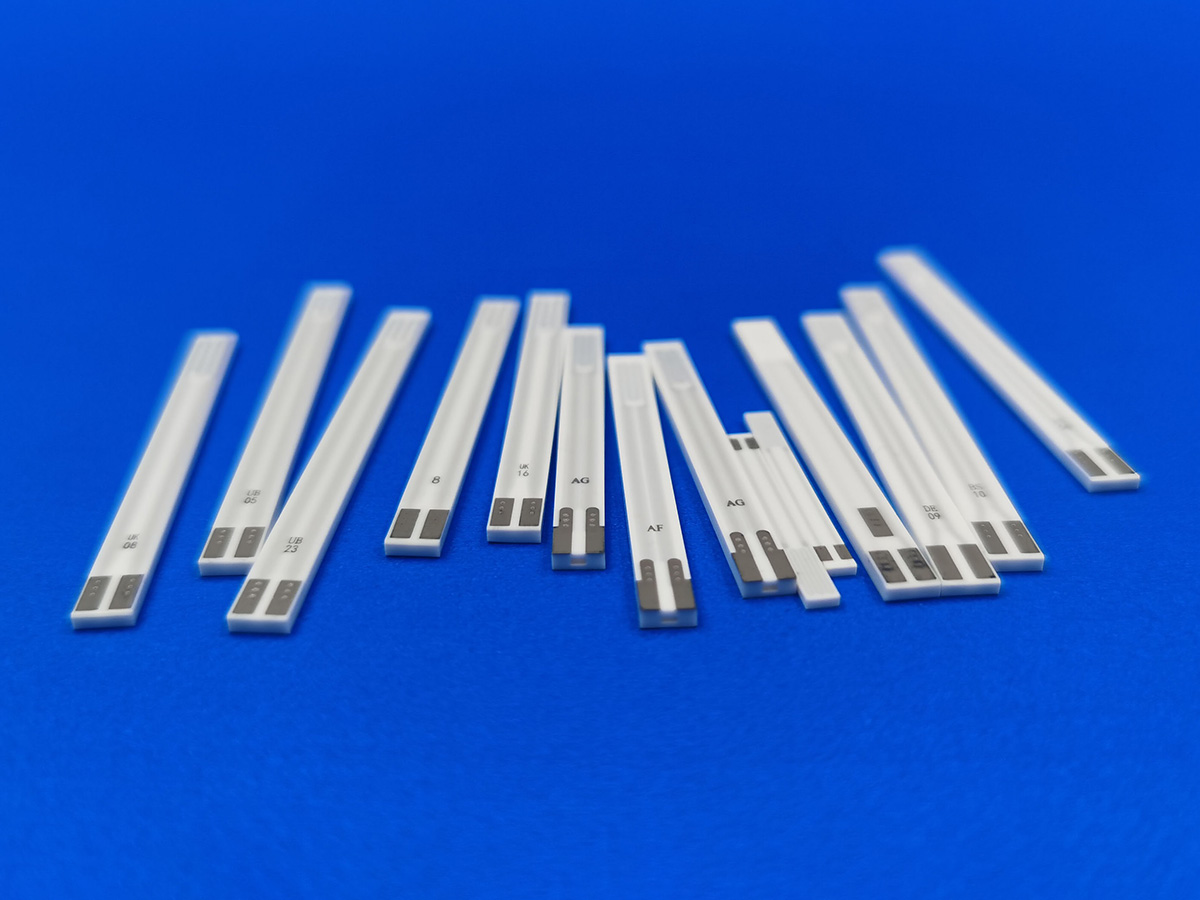

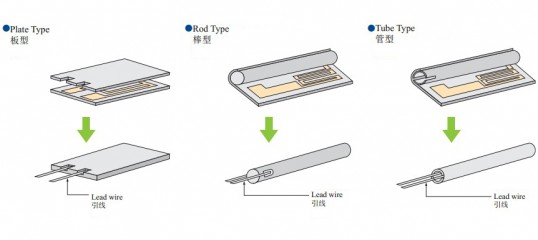

Heater Design Structure

The heating element of the ceramic heater is built into a substrate of alumina or silicon nitride material, then laminated and sintered into one piece — providing insulation and protection from the outside environment.

HTCC (High Temperature Co-Ceramics) Advantages:

- Customized solutions based on a variety of manufacturing processes

- Efficient solutions due to high degree of design support from the beginning of the product development cycle

- Availability of a variety of mechanical, thermal (ANSYS, ABACUS), optical (ZEMAX) and electrical (HFSS, ADS) simulation tools

- Worldwide customer support from local manufacturing facilities with technical competence centers

Characteristics of HTCC:

- Excellent mechanical stability

- Easy integration into metal housings due to matched thermal coefficient of expansion

- High thermal conductivity

- Use of non-noble metal pastes

- Additional plating reveals solderable and wirebondable surfaces

Enquiry

Enquiry