Ceramic-to-Metal Sealing Materials:

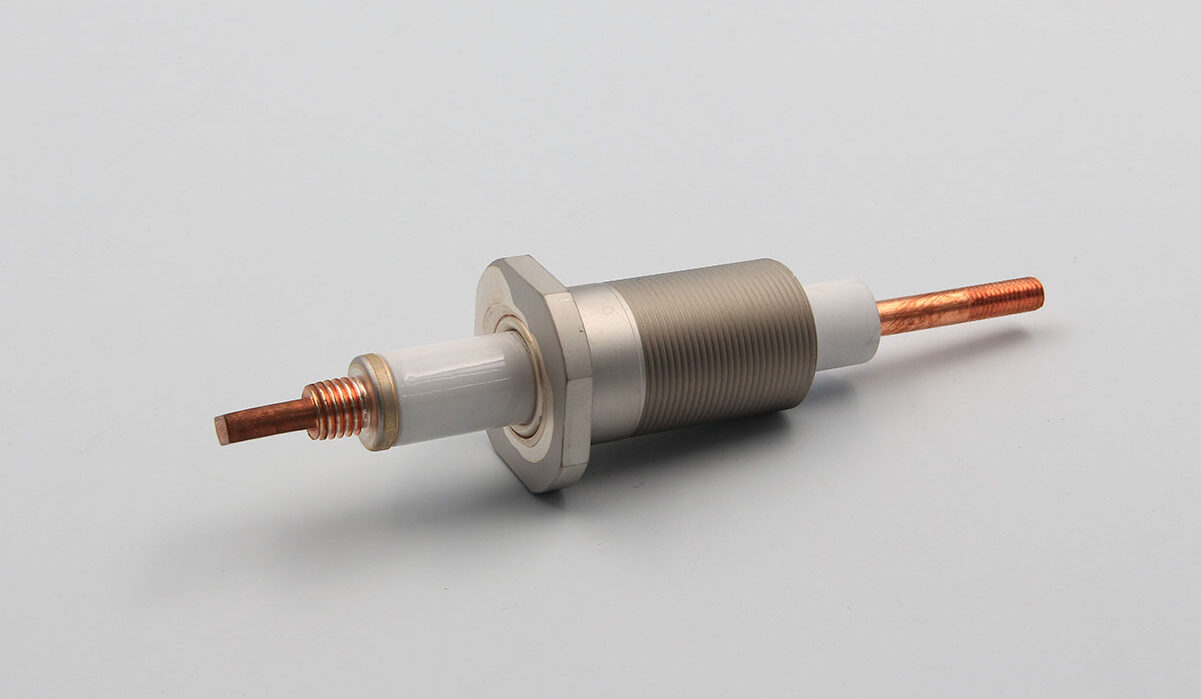

| Housing Material | Insulator | Conductor |

| NiFe Alloys & NiFeCO (Kovar) |

94%-99% Al2O3 | Kovar ; Copper Cored Kovar |

| 300 & 400 Series SST | AlN | 52 Alloy |

| Cu and Cu Alloys | BeO | Inconel |

| Inconel | Stainless Steels | |

| 42, 46, 49 Alloys |

Hermetic Seal Properties:

- Hermeticity: up to 1×10-9 atm cc/sec He

- Working Temperature > 500°C depending on materials and geometry

- Insulation Resistance: Typically exceeds 1 GΩ @ 100 VDC

Ceramic-to-Metal Sealing Features:

- High Abrasion Resistance

- High Mechanical Strength

- Pressures over 10,000 PSI

- High Temperature Usage

- Low Dielectric Loss

- Mass Spectrometer Leak Tested

- High Chemical Stability

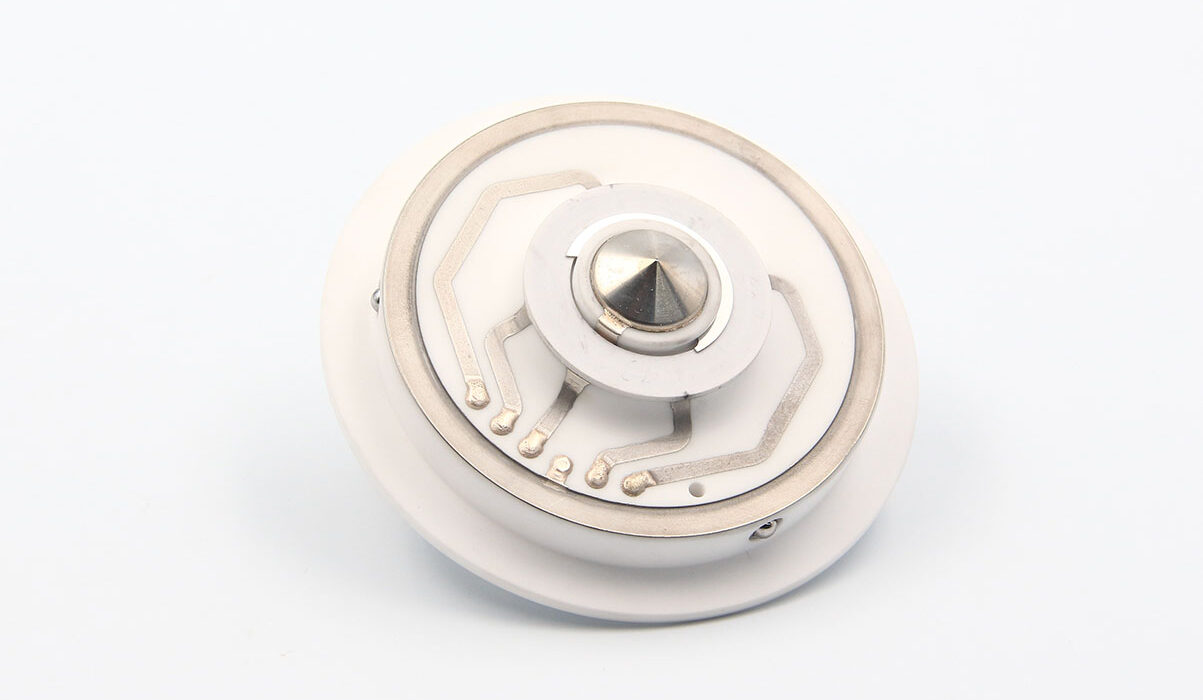

Ceramic-to-Metal Welding Process:

- Cleaning

- Pasting

- Metallizing

- Nickel Plating

- Mounting

- Brazing

- Inspection&Packing

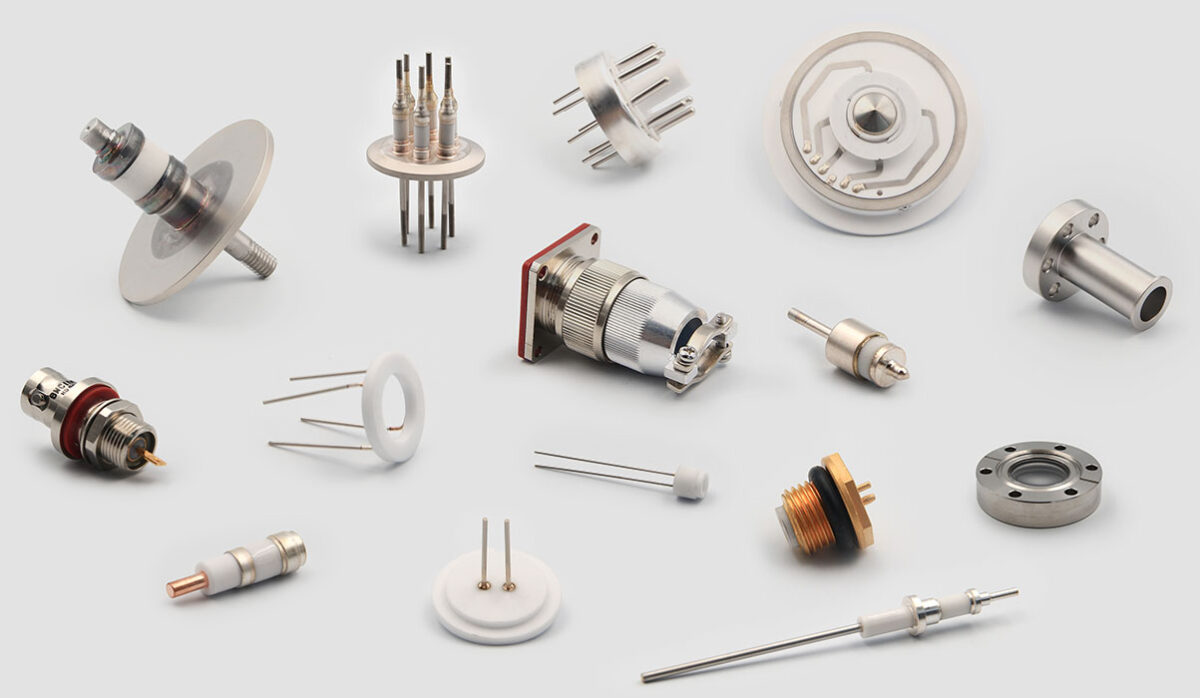

Ceramic-to-Metal Sealing Applications:

- Relay Insulators

- Capacitor

- Magnetrons

- Travelling Wave Tube

- X-ray Tube Components

- Electrosurgical Instrumentation

- Implantable Packages and Feedthroughs

- Gas Detectors

- Microscopes (TEM, SEM)

- High Voltage Feedthroughs

- High-temperature Feedthroughs

- RF Feedthroughs

- Optoelectronics and Power Tube

- Laser Tubes

- Thyristors

- Diodes

- And etc

Enquiry

Enquiry