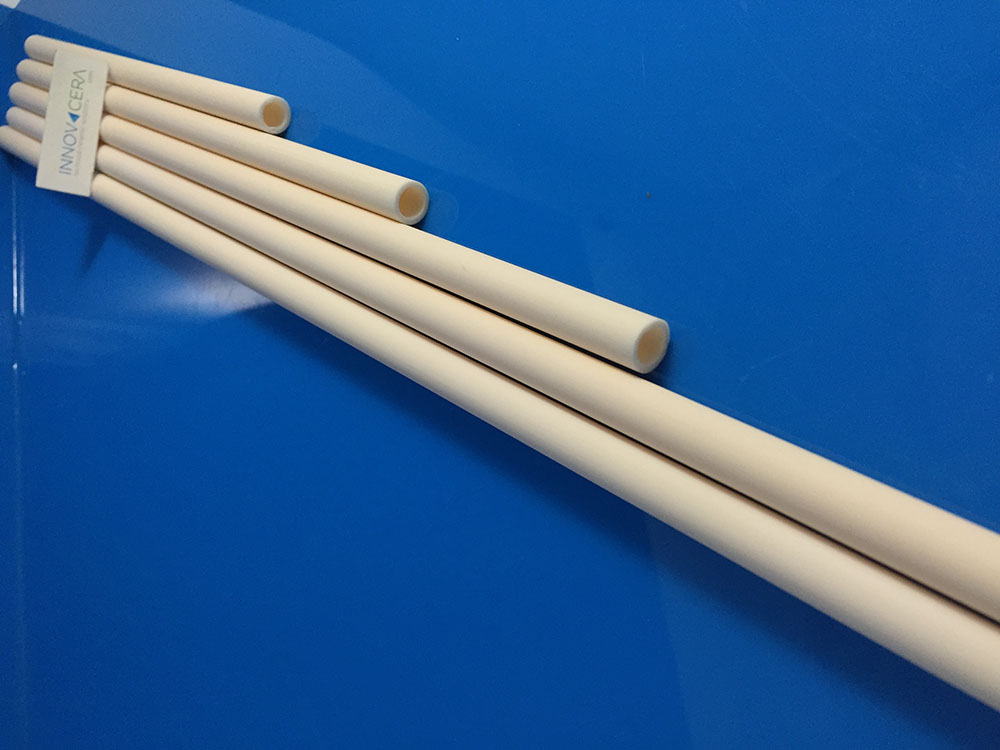

Materials:

By operating temperature, due to variable alumina, it is further divided into 99.5 (corundum), 99 (corundum), 95 (corundum), 85 (alumina porcelain), 75 (mullite porcelain), for materials above, the more the alumina, the higher the operating temperature, the maximum aluminum content vertical use at 1710°C,the minimum aluminum use at 1100°C.

Application:

Mainly used for protection of thermometric elements, to isolate them from outside and reduce or prevent them being corroded, oxidized, or damaged during use.

Stock size of protective tube:

Outer diameter 4mm to 30mm, maximum length 1600mm, wall thickness by dimension scale of product 0.5mm to 4mm.

How to use ?

During use, the thermometric element is insulated well put into the protective tube, and then the open end and the couple ends are sealed with high-temperature clay. When in measurement, the sealed end is inserted into the temperature measuring zone, and it is best to prevent shock cooling or heating from damaging the protective tube during use.

Enquiry

Enquiry