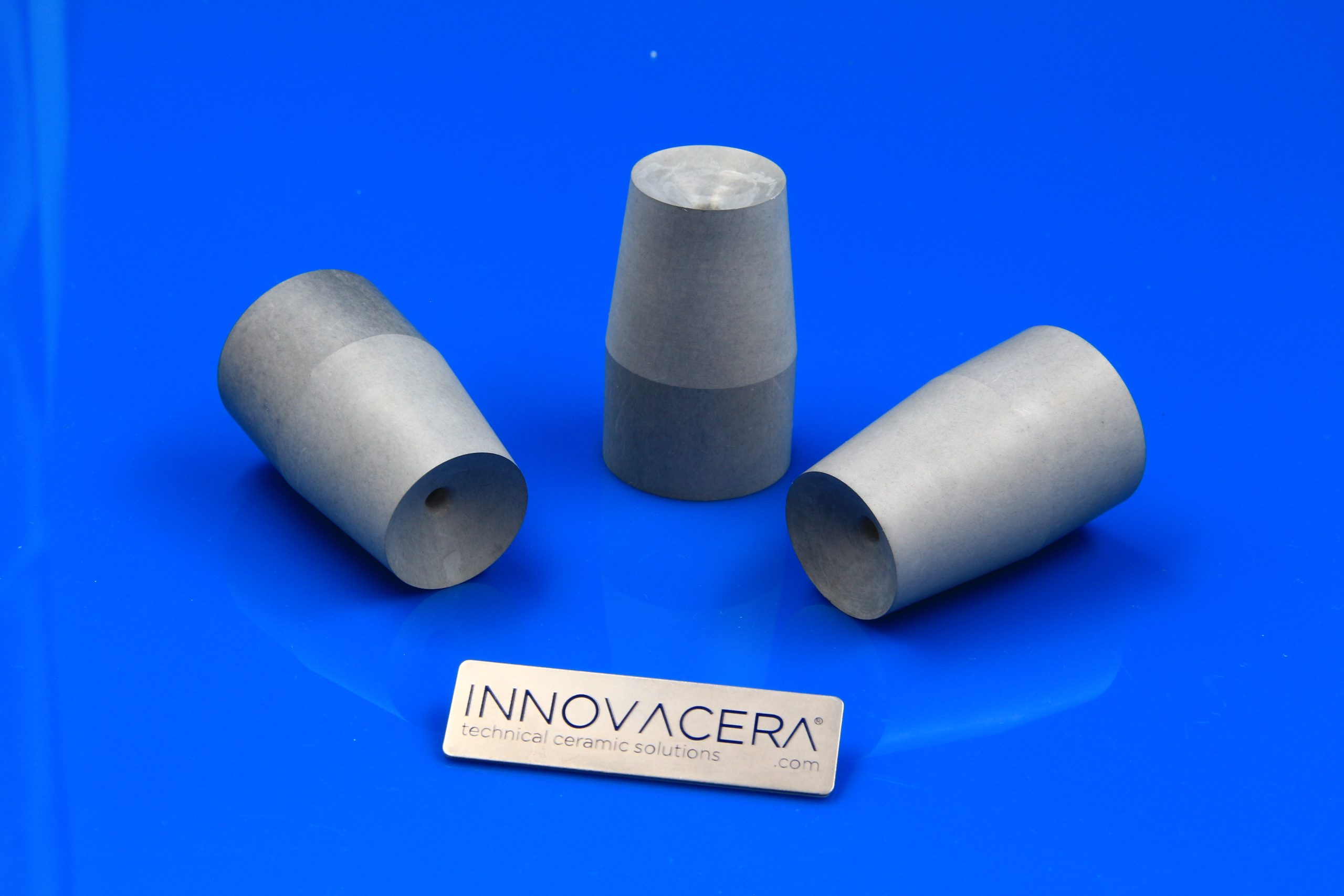

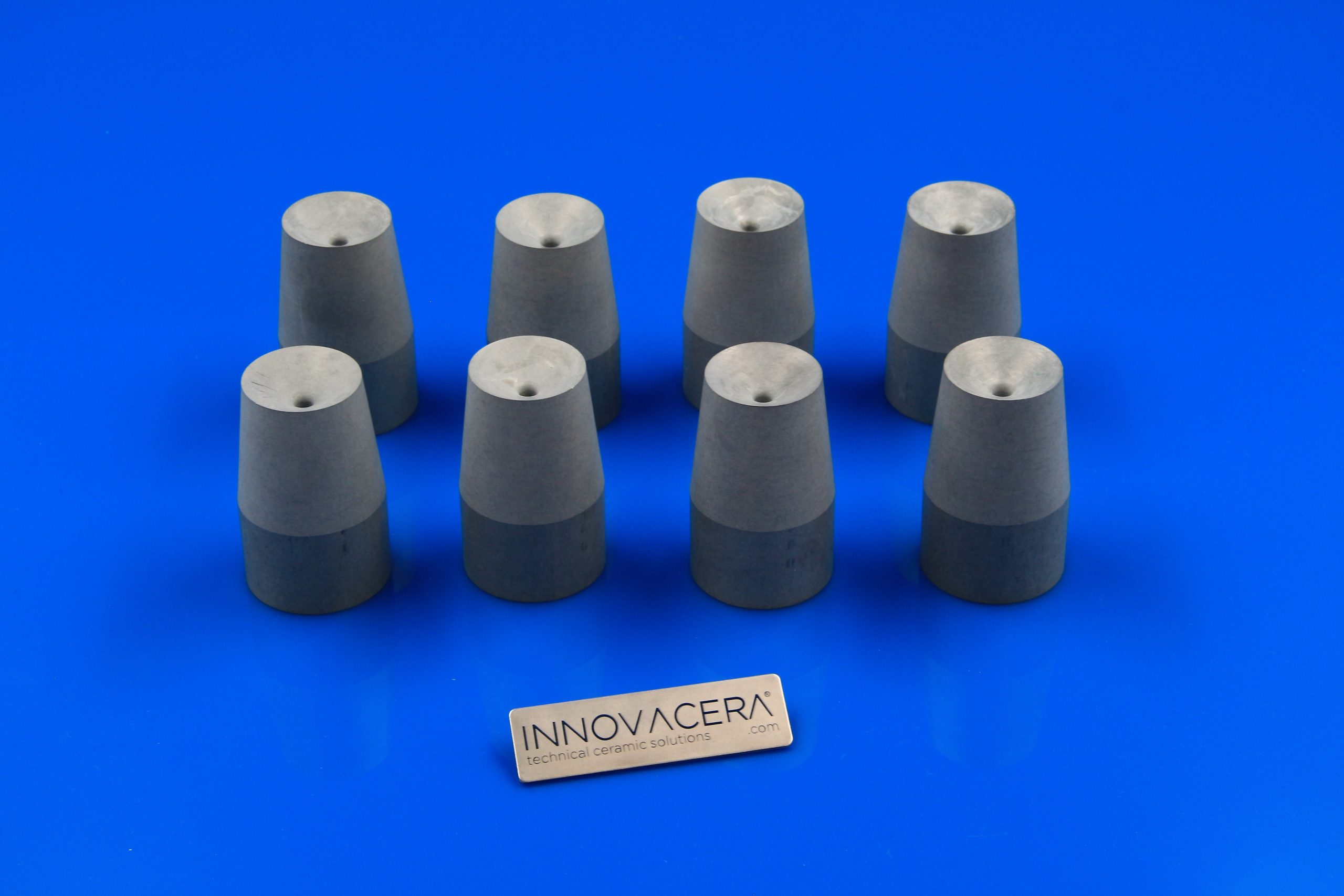

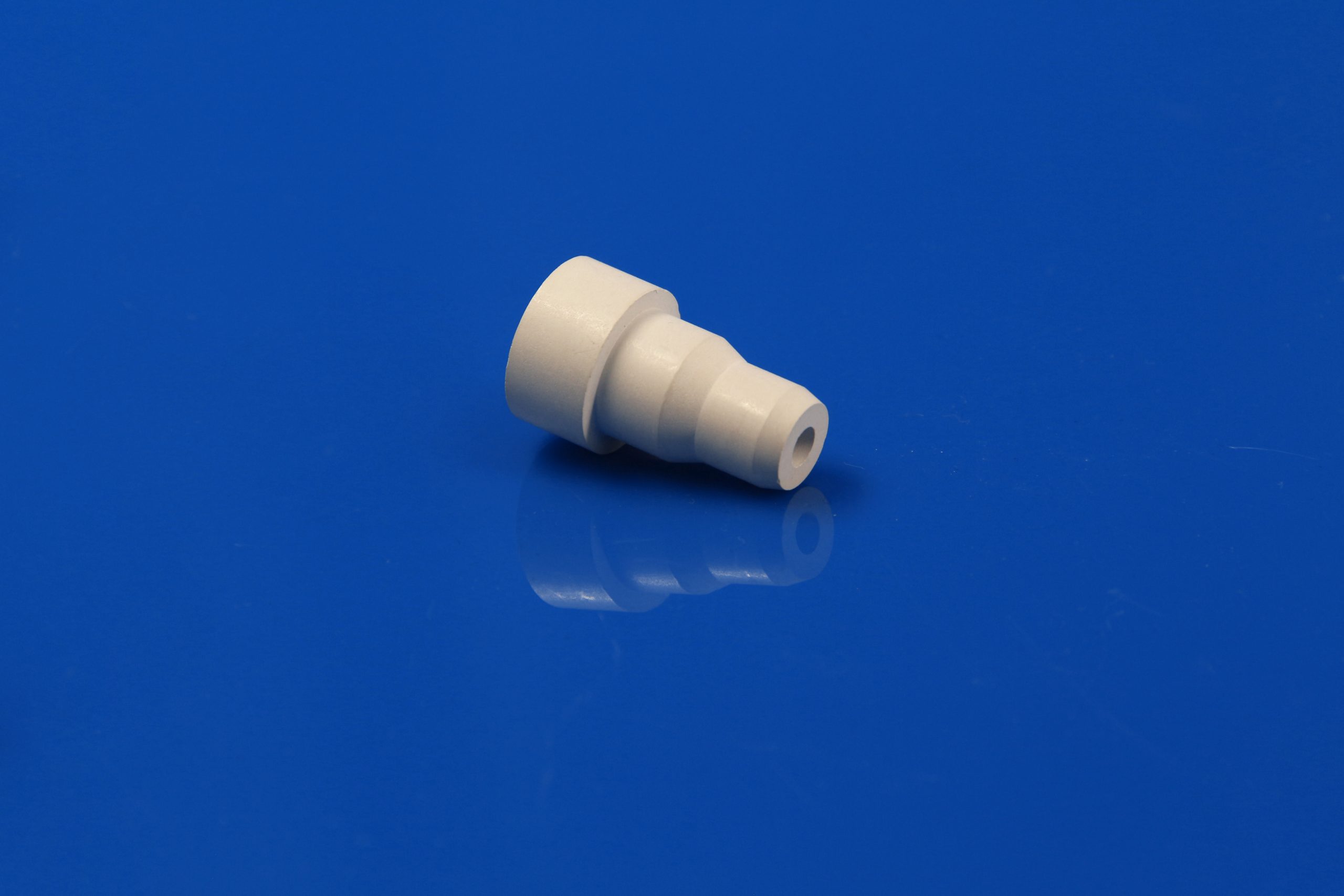

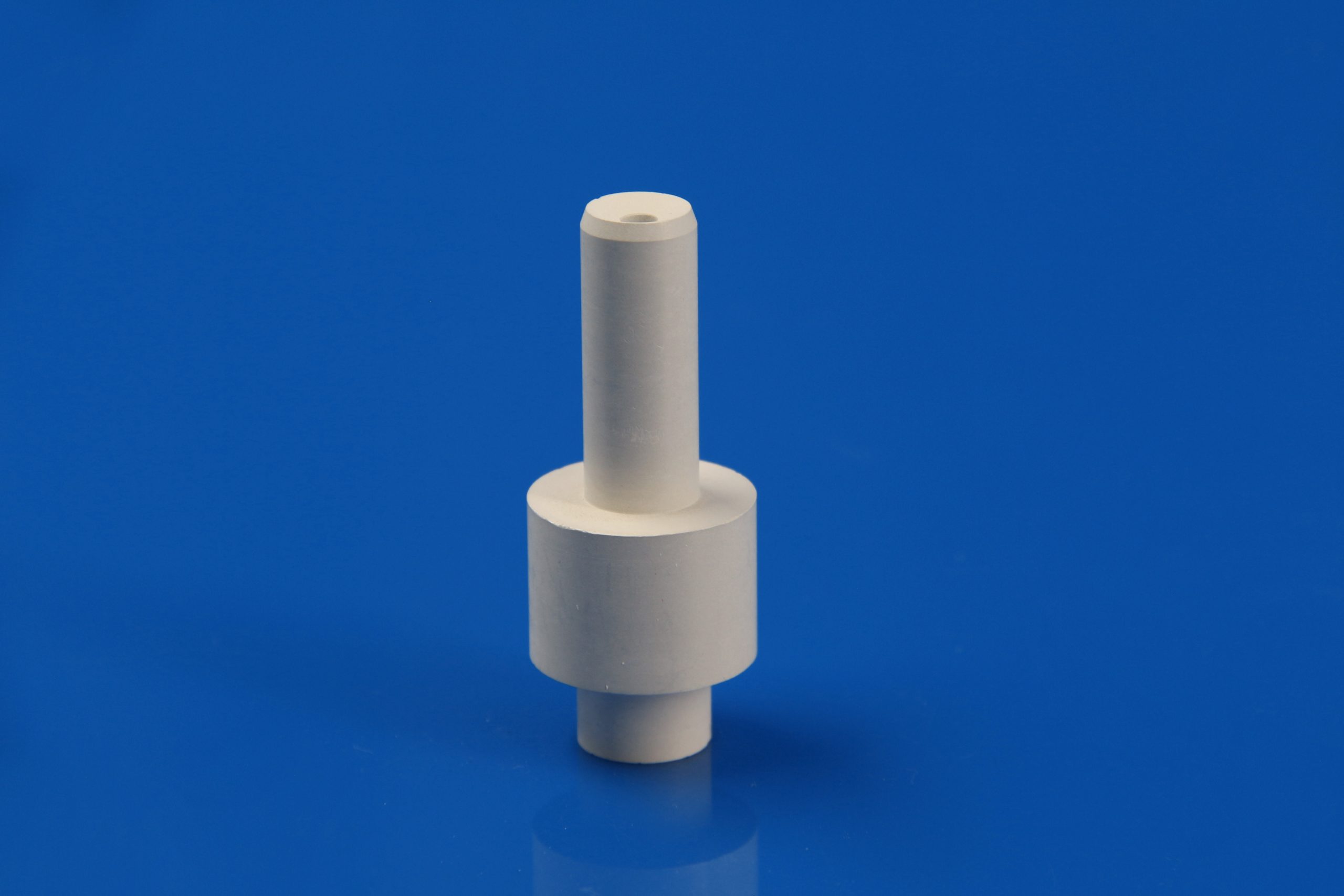

Innovacera BMA Boron Nitride Atomization Nozzles Advantages:

-Achieve tight particle size distribution & high yield: Unlike traditional pressed/sintered zirconia or alumina nozzles, BMA’s low friction coefficient, smooth surface, and precise tolerances eliminate clogging and metal creep. This ensures consistent, stable atomization—even during startup—for specialty powders (Ni, Cu, Al alloys).

-Reduce costs & downtime: Minimize scrap rates, tedious cleaning, and frequent nozzle replacements. BMA nozzles offer outstanding thermal shock resistance, requiring minimal preheating. Easily machined for rapid prototyping and complex shapes.

-Optimize your molten metal processing: Choose Innovacera BMA for predictable performance, extended service life, and maximized efficiency.

Enquiry

Enquiry