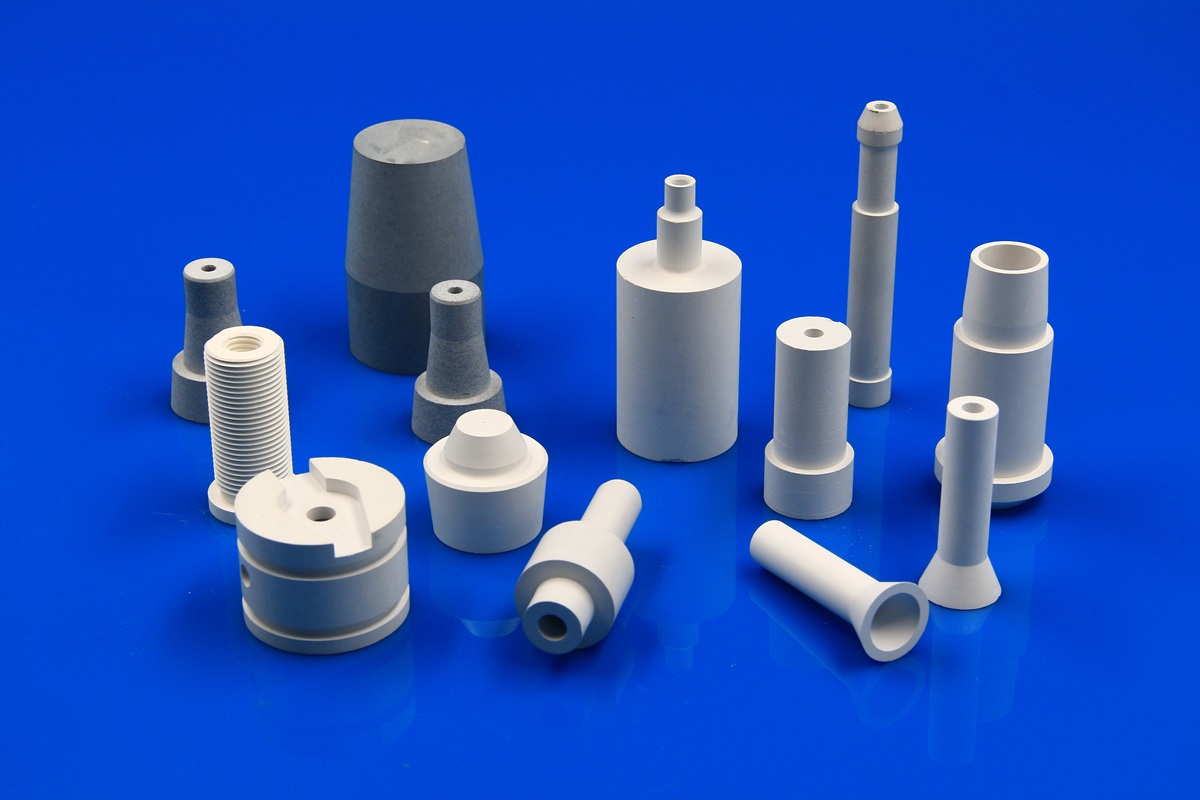

Mainly used in powder metallurgy industry or 3D printing, gas atomization process production of metal powder, such as iron powder, aluminum powder, copper powder, nickel-based alloy powders stainless steel, welding powder, Fe-Si aluminum, Fe-Si nickel, aluminum, iron, boron, etc.

Prime Features of Boron Nitride Gas Atomizing Nozzles

-Max using temperature: 1800°C

-Applicable environment: air, vacuum, or atmosphere protection environment

-Metal corrosion resistance in high temperature

-Non-bonding and non-reaction with metal liquid

-Wear-resistant and erosion-resistant to metal liquids

-High thermal shock resistance

-The formula can be designed according to customer’s using environment.

Material Properties

| Properties | Units | BMA | BSC | BMZ | BSN |

| Main Composition | – | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+SI3N4 |

| Color | – | White Graphite | Greyish-Green | White Graphite | Dark Gray |

| Density | g/cm3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.2-2.3 |

| Three-Point Bending Strength | MPa | 65 | 80 | 90 | 150 |

| Compressive Strength | MPa | 145 | 175 | 220 | 380 |

| Thermal Conductivity | W/m·k | 35 | 45 | 30 | 40 |

| Thermal Expansion Coefficient (20-1000℃) | 10-6/K | 2 | 2.80 | 3.5 | 2.80 |

| Max Using Temperature

In Atmosphere In Inactive Gas In High Vacuum (Long Time) |

(℃) | 900

1750 1750 |

900

1800 1800 |

900

1800 1800 |

900

1800 1800 |

| Room Temperature Electric Resistivity | Ω·cm | >1013 | >1012 | >1012 | >1013 |

| Typical Application | – | Powder Metallurgy | Powder Metallurgy | Metal Casting | Powder Metallurgy |

| High Temperature Electrical Furnace Components | – | √ | √ | √ | |

| Metal Vaporize Crucible | |||||

| The Container of Metal

or Glass Melting |

– | √ | √ | √ | |

| The Casting Mould Components of The Precious Metal and Special Alloy. | – | √ | – | – | |

| High Temperature

Support Part |

– | √ | – | √ | |

| Nozzle and Transport Tube of The Melting Metal | – | √ | √ | √ | √ |

| Nitrides Sintering

(Sagger and Setter Plate) |

– | – | – | – | √ |

Prime Features of Zirconia Gas Atomizing Nozzles

-Max using temperature: 2200°C

-Applicable environment: air, vacuum, or atmosphere protection environment

-Metal corrosion resistance in high temperature

-Wear-resistant and erosion-resistant to metal liquids

-High thermal shock resistance

-The stabilizers and grains combination can be designed according to customer’s using environment.

Technical Indicators

| Indicators | Item | Units | MSZ-H | MSZ-L |

| Main Composition | ZrO2 | % | ≥95 | 95-96 |

| Al2O3 | % | ≤0.2 | ≤0.2 | |

| SiO2 | % | ≤0.4 | ≤0.4 | |

| MgO | % | ≤2.9 | ≤2.9 | |

| Fe2O3 | % | ≤0.1 | ≤0.1 | |

| TiO2 | % | ≤0.1 | ≤0.1 | |

| Physical | Color | – | Yellow | Yellow |

| Density | g/cm3 | ≤5.4 | 5.45-5.60 | |

| Porosity | % | ≤18.5 | ≤8 |

Enquiry

Enquiry