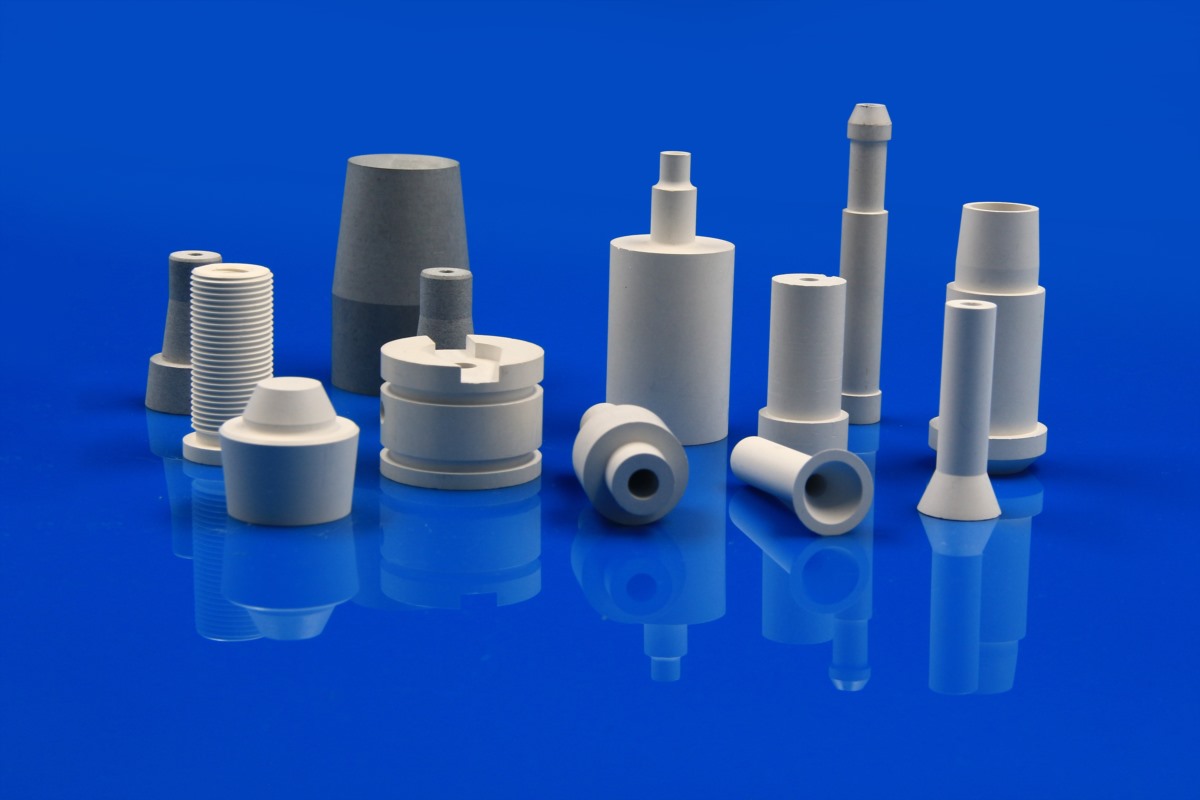

In powder metallurgy (PM) processes, boron nitride and zirconia ceramic nozzles are used depending on the type of metal materials.

Main Features of Ceramic Nozzles

High-temperature resistance: withstands temperatures above 1500 °C from molten metals or plasma flames.

Wear resistance: resists erosion from powder or gas flow for long-term operation.

Chemical inertness: does not react with active metals or gases.

Applications at Different Stages of Powder Metallurgy

| Stage | Process | Functions of Nozzles | Ceramic Nozzles | Typical Metals |

|---|---|---|---|---|

| Powder Preparation | Gas Atomization | High-pressure inert gas (such as nitrogen or argon) impinges on the molten metal stream to form fine powder; ceramic nozzles control flow and particle size. | Boron Nitride and Zirconia | High-purity or reactive metals such as titanium and nickel-based alloys. |

| Water Atomization | Ceramic nozzles provide corrosion resistance and precise flow control. | Zirconia | Used in high-pressure water atomization for preparing low-cost powders such as iron-based powders. | |

| Powder Spraying or Deposition | Thermal Spraying | During coating or preform preparation (e.g., plasma spraying or HVOF), ceramic nozzles spray metal powders onto substrates to form dense coatings. | Boron Nitride and Zirconia | Applicable to all metal powders. |

| Powder Transportation and Treatment | Fluidized Bed or Pneumatic Transportation | Ceramic nozzles are used to control gas flow, evenly disperse or convey powders, and prevent agglomeration or clogging. | Boron Nitride and Zirconia | Tungsten, molybdenum, iron, cobalt, nickel, aluminum, titanium, tantalum, and other active metal powders. |

| Treatment After Sintering | Cooling or Atmosphere Control | Ceramic nozzles spray inert gases (e.g., hydrogen, nitrogen) or cooling media to control furnace atmospheres and accelerate part cooling to prevent oxidation. | Boron Nitride and Zirconia | High-performance metal powders such as high-speed steel, titanium alloys, and amorphous/metallic glass powders. |

| 3D Printing (e.g., Binder Jetting) | – | Ceramic nozzles are used to accurately spray binders or metal slurries. | Boron Nitride and Zirconia | Powder metallurgy additive manufacturing applications. |

| Degreasing or Cleaning | – | Ceramic nozzles are used to remove temporary binders or residual powder from compacts. | Zirconia | Titanium and its alloys, nickel-based superalloys, aluminum alloys, cobalt-chromium alloys, refractory metals (tungsten, tantalum, molybdenum), precious metals (gold, silver, platinum), and high-entropy alloys. |

Table 1: Boron Nitride Ceramic Nozzle Properties

| Properties | Units | BMA | BSC | BMZ | BSN |

|---|---|---|---|---|---|

| Main Composition | – | BN + Zr + Al | BN + SiC | BN + ZrO₂ | BN + Si₃N₄ |

| Color | – | White Graphite | Greyish-Green | White Graphite | Dark Gray |

| Density | g/cm³ | 2.25–2.35 | 2.4–2.5 | 2.8–2.9 | 2.2–2.3 |

| Three-Point Bending Strength | MPa | 65 | 80 | 90 | 150 |

| Compressive Strength | MPa | 145 | 175 | 220 | 380 |

| Thermal Conductivity | W/m·K | 35 | 45 | 30 | 40 |

| Thermal Expansion Coefficient (20–1000 °C) | 10⁻⁶/K | 2.0 | 2.8 | 3.5 | 2.8 |

| Max Using Temperature (Atmosphere / Inactive Gas / High Vacuum) | °C | 900 / 1750 / 1750 | 900 / 1800 / 1800 | 900 / 1800 / 1800 | 900 / 1800 / 1800 |

| Room Temperature Electric Resistivity | Ω·cm | >10¹³ | >10¹² | >10¹² | >10¹³ |

| Typical Applications | – | Powder metallurgy, metal casting, high-temperature furnace components, crucibles, casting molds for precious and special alloys, high-temperature supports, and nozzles or transport tubes for molten metals. | |||

Table 2: Zirconia Ceramic Nozzle Indicators

| Indicators | Item | Units | MSZ-H | MSZ-L | Custom |

|---|---|---|---|---|---|

| Main Composition | ZrO₂ | % | ≥95 | ≥95 | 60–95 |

| Al₂O₃ | % | ≤0.2 | ≤0.2 | 0.2–20 | |

| SiO₂ | % | ≤0.4 | ≤0.4 | 0.2–1 | |

| MgO | % | ≤2.9 | ≤2.9 | MgO | |

| Fe₂O₃ | % | ≤0.1 | ≤0.1 | 0.1–0.3 | |

| TiO₂ | % | ≤0.1 | ≤0.1 | 0.1–1.0 | |

| Physical Properties | Color | – | Yellow | Yellow | Yellow / White |

| Density | g/cm³ | ≤5.2 | 5.4–5.6 | 4.6–5.6 | |

| Porosity | % | ≤18.5 | ≤8 | 1–18.5 | |

| The stabilizers, grain composition, and porosity can be customized according to specific operating environments. | |||||

Enquiry

Enquiry