It’s widely used in the fields of research, semiconductors, vacuum electronics and analytical instruments and is suitable for systems that require high signal integrity and high vacuum compatibility.

KF40 indicates that it adopts the ISO-KF40 flange standard (with an outer diameter of approximately 55 mm), and can be quickly installed at high vacuum pipelines or cavity interfaces, balancing both sealing reliability and installation convenience.

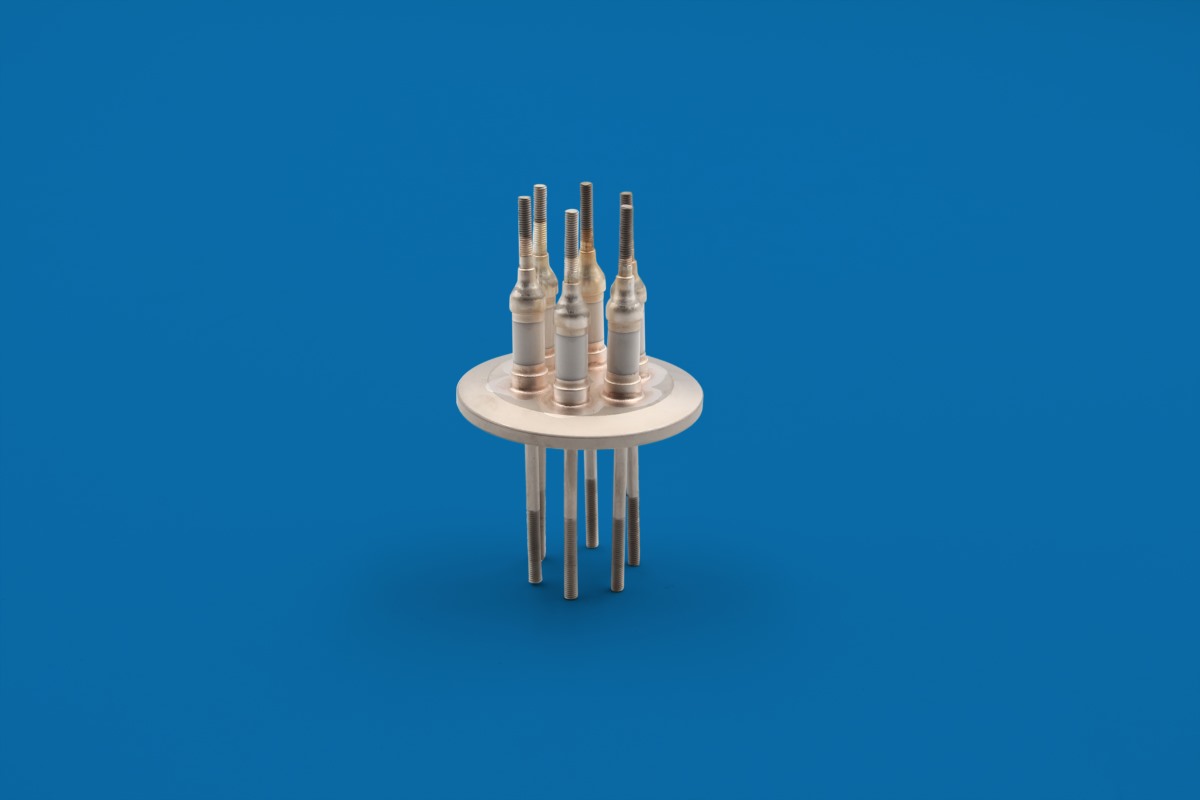

Main structure and configuration options

According to different application requirements, the BNC KF40 feeder transceiver offers various configuration options in the following key parameters.

1.Number of conductors / contacts

– Single-channel (1–2 contacts)

Suitable for single-channel signal or standard coaxial signal transmission

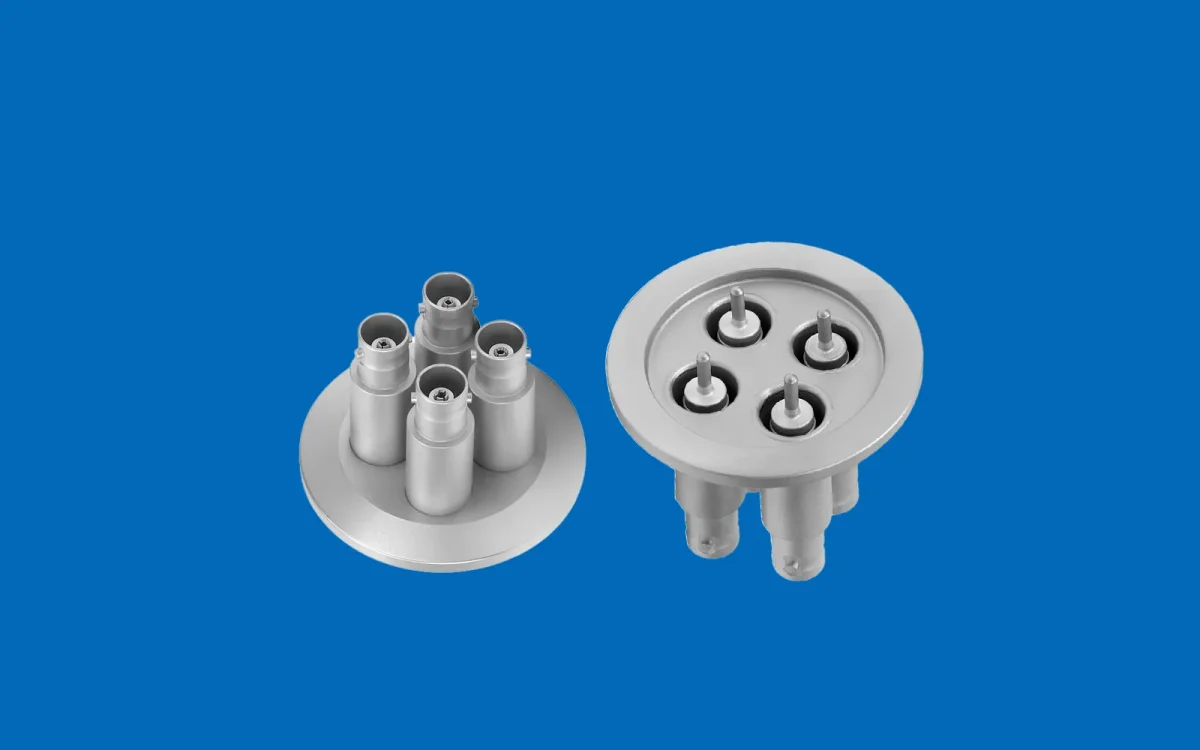

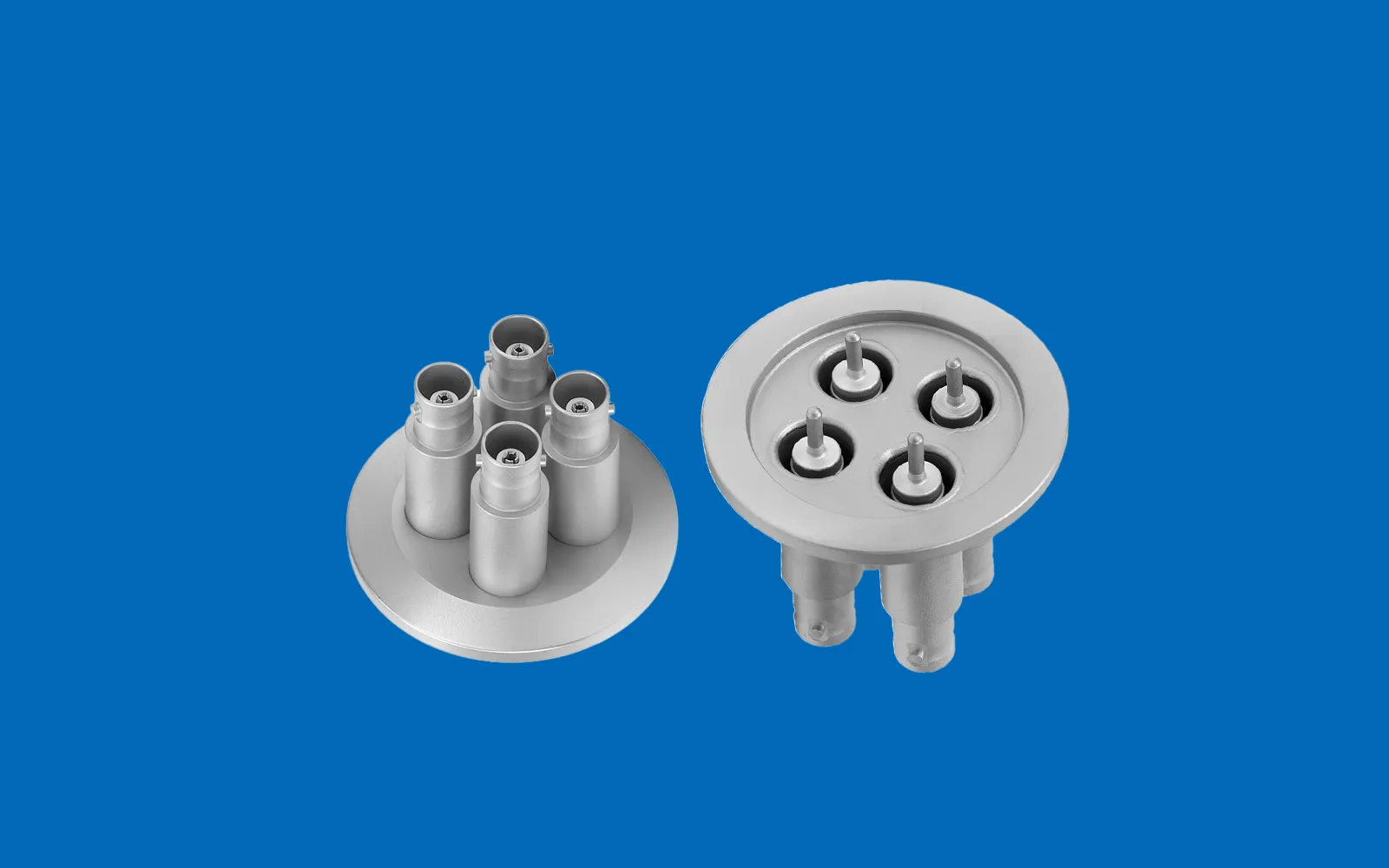

– Multiple channels (such as 4 × BNC)

Integrating multiple independent signal interfaces on a single KF40 flange, suitable for multi-signal synchronous transmission and applications with high requirements for system integration.

2.Impedance Matching Method

– 50 Ω impedance-matched type

Designed specifically for RF and high-frequency signals, it effectively reduces reflections and signal distortion, ensuring signal integrity.

– Non-impedance-matching type

Suitable for transmission of DC signals or low-frequency signals, such as control signals, power introduction, etc.

3.Shielding and Grounding Methods

– Grounding Shielded Type

The coaxial shielding layer is directly electrically connected to and grounded to the flange, which is the most common configuration and can effectively suppress electromagnetic interference.

– Floating Ground Shielding Type

The shielding layer is electrically isolated from the flange, and is suitable for special circuit designs that involve potential differences in ground or are sensitive to grounding.

4.Interface Position Form

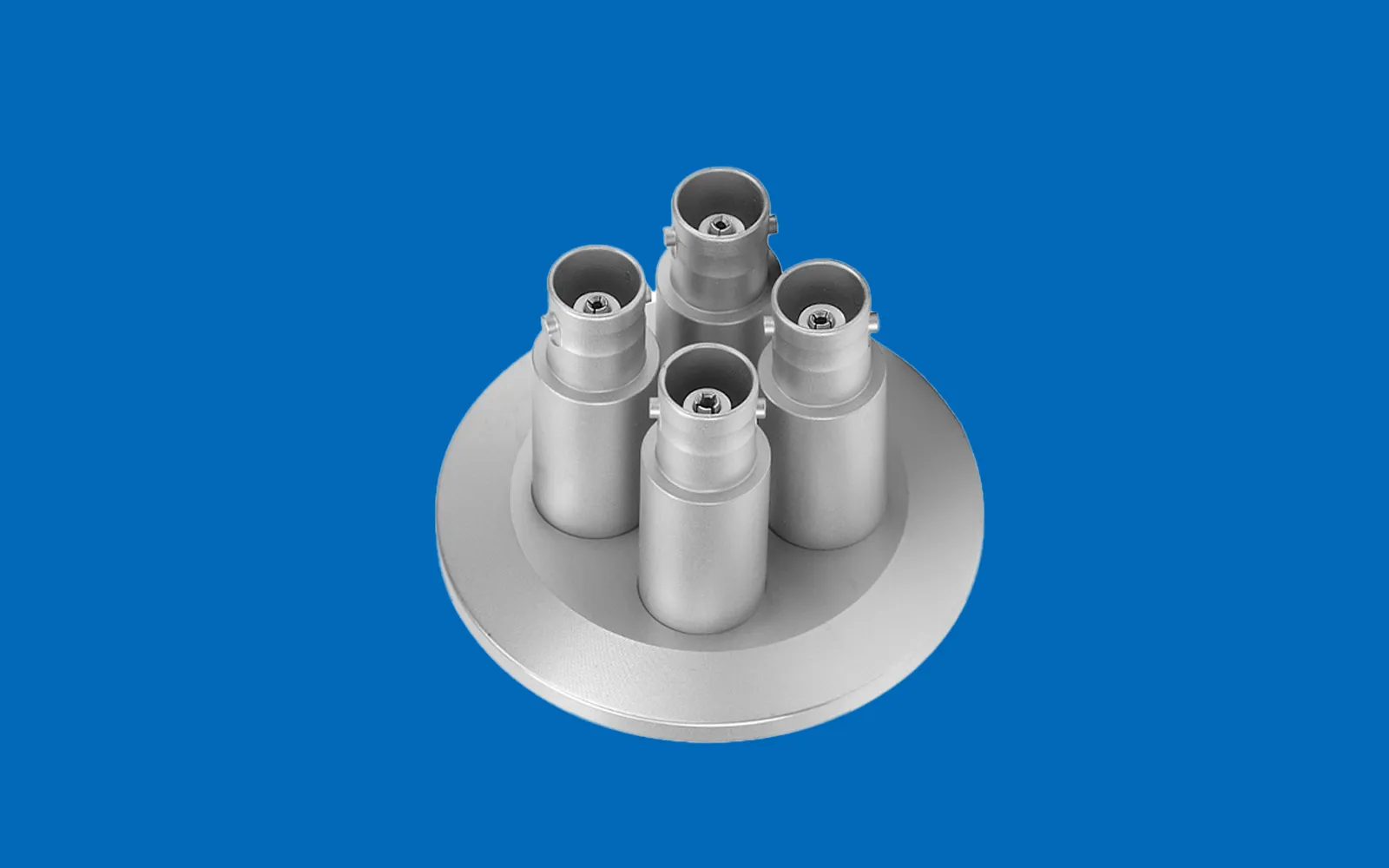

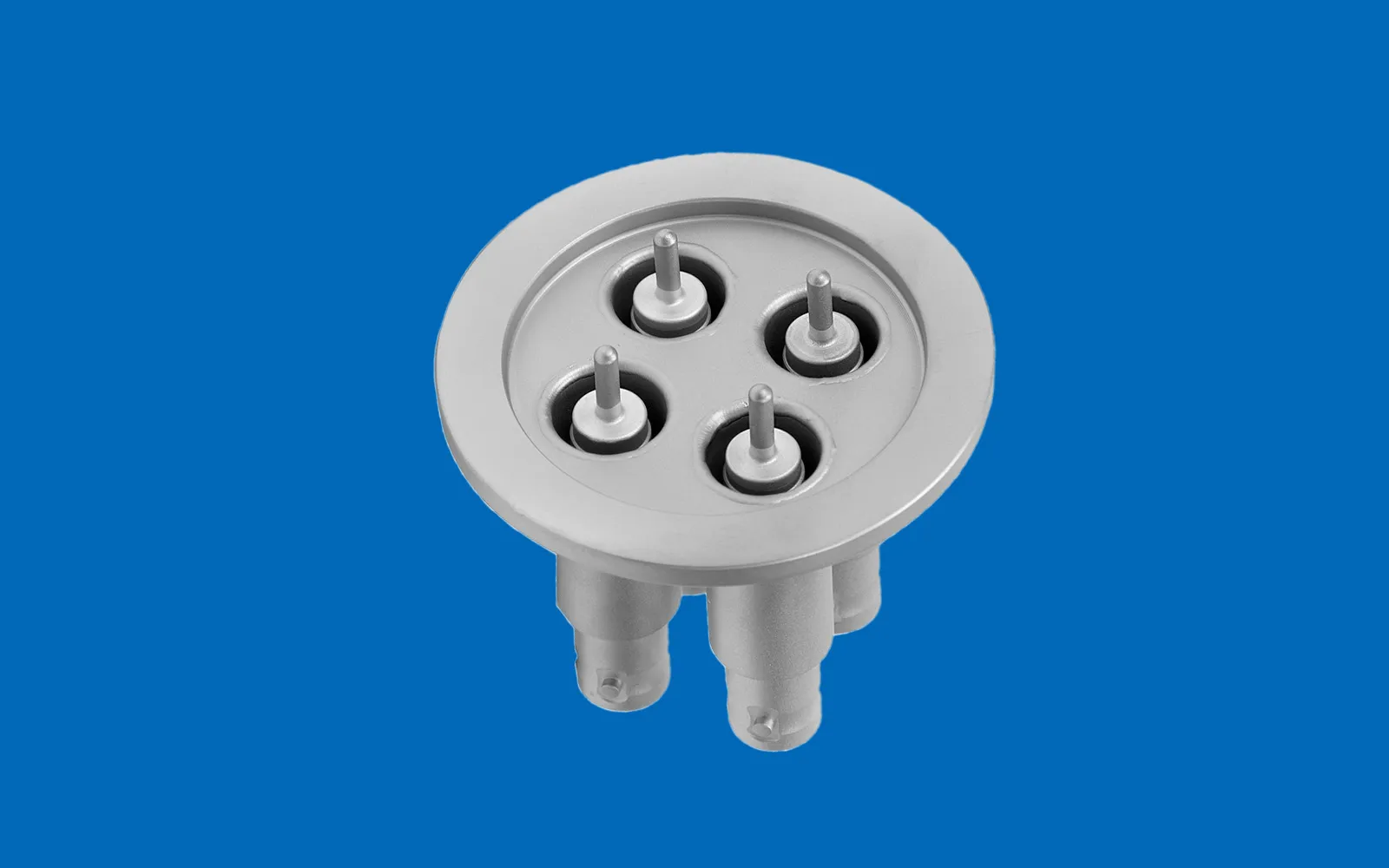

– Single-side Outlet (Air Side BNC)

The air side features a standard BNC interface, while the vacuum side is composed of pins or soldering terminals, facilitating flexible wiring within the cavity.

– Dual outlet (both the air side and the vacuum side use BNC connectors)

Both the inner and outer sides feature BNC interfaces, making installation and replacement much faster and suitable for modular system design.

Technical Parameters

– Rated Voltage:≤ 500 V DC

– Rated Current:Single contact approximately 3 A

– Leakage Rate:≤ 1 × 10⁻⁹ mbar·L/s

– Maximum Baking Temperature:150 °C (can be increased according to design)

– Flange Standard:ISO-KF40

Materials and Techniques

– Flange / Body: 304 / 304L stainless steel

– Insulator: High-purity alumina ceramic

– Sealing Method: Metal-ceramic vacuum brazing

Application

– High vacuum and ultra-high vacuum systems

– Radio frequency and signal introduction modules

– Semiconductor processing equipment

– Analytical instruments such as mass spectrometers and electron microscopes

– Vacuum experiments and research devices

Enquiry

Enquiry