In semiconductor equipment, industrial control systems, and high-reliability electronic systems, the package not only provides electrical connections but also directly affects the long-term stability of the device in high-temperature, vacuum, or otherwise demanding environments. Although traditional plastic-encapsulated SOP packaging is cost-effective and fast to produce, it is susceptible to aging, leakage, or performance degradation under high humidity, high temperature, and long-term operation conditions.

In contrast, ceramic packaging has inherent advantages in terms of air tightness, material stability, and service life. Among them, Ceramic Small Outline Package (CSOP) is a type of ceramic package that combines mature manufacturing techniques with surface mount requirements. It integrates the high stability of ceramic materials with the compact form factor of SOP (Surface Mount Package), and is widely used in electronic systems that have high requirements for reliability and process stability.

01 What is a CSOP ceramic tube shell?

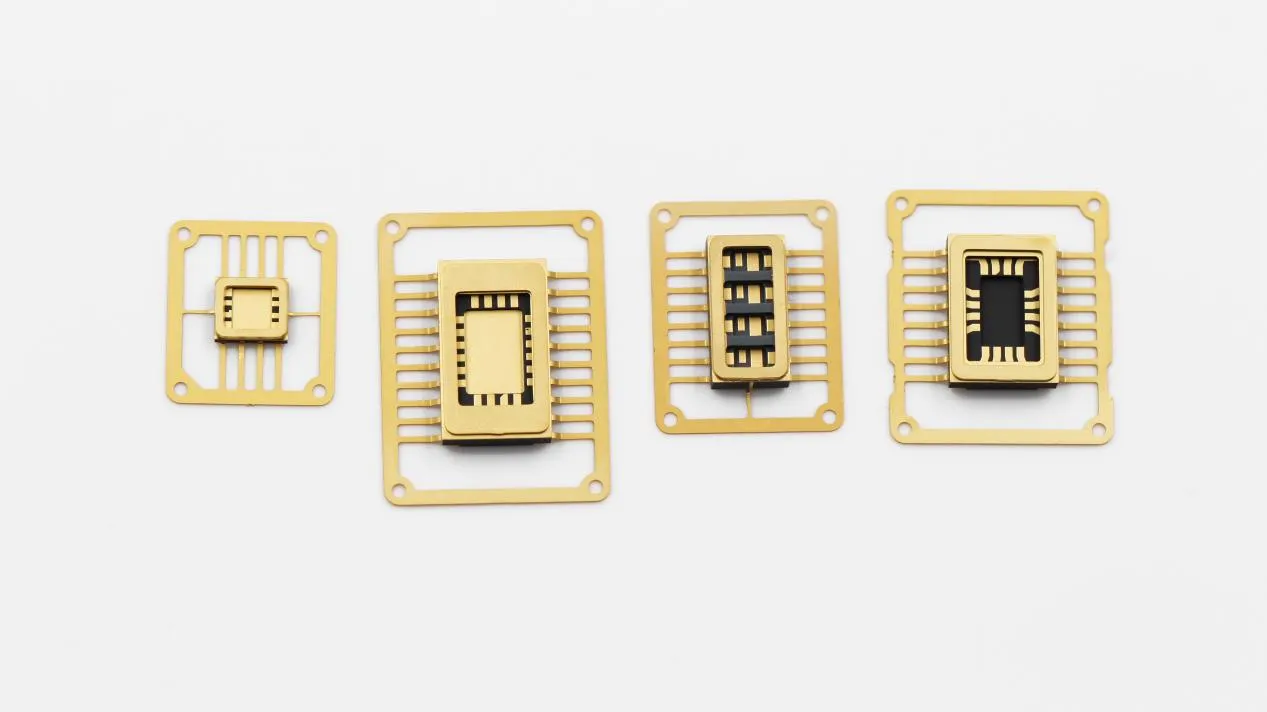

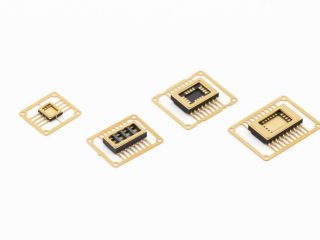

CSOP is a ceramic gas-sealed housing developed based on the Small Outline Package (SOP) structure.

Its typical characteristics include:

– Using alumina or aluminum nitride ceramics as the matrix material.

– Two-sided pins or metallized pads for SMT assembly.

– An internal sealed cavity can be formed, which is used for chip mounting and lead bonding.

– Provides gas-tight sealing by using ceramic caps or metal caps.

While maintaining the familiar form factor and mature manufacturing process of the SOP packaging, the CSOP adopts ceramic materials to enhance its high-temperature stability and long-term reliability. It can protect the performance and lifespan of the chip in harsh environments such as humidity, temperature or vacuum. Meanwhile, its through-hole compatible design also makes the production process more flexible, enabling automated SMT assembly and facilitating system repair and maintenance.

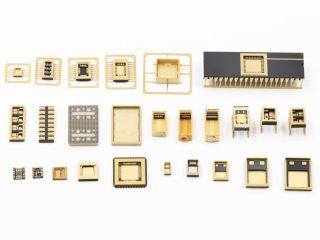

02 The Positioning of CSOP in the Ceramic Tube Shell System

In the entire ceramic tube housing product line, CSOP does not aim for the highest pin density or the smallest package size. Instead, it serves as a basic and reliable solution, providing stable support for semiconductor equipment, industrial control modules, and aerospace electronic systems.

Compared with forms such as CLCC and CQFN that have no pins or are of high-density, CSOP places greater emphasis on the following characteristics:

– Mature structure, with sufficient long-term application verification.

– More friendly to PCB design and soldering processes.

– It has better tolerance under thermal cycling and mechanical stress.

– Easier for detection, repair and system-level maintenance.

Therefore, CSOP is often chosen for systems that emphasize reliable performance and long-term reliability, rather than simply pursuing the limits of package size or pin count.

03 Typical Application Domains

CSOP ceramic tubes are commonly used in the following application scenarios:

– Semiconductor manufacturing and testing equipment: Sensors and control modules for use in high-temperature, vacuum or clean environments, ensuring stable device performance.

– Industrial control and sensing systems: In complex environments such as those with temperature, humidity or vibration, they provide airtight protection and thermal stability, thereby extending the lifespan of the modules.

– Aerospace and high-reliability electronic equipment: Capable of withstanding temperature fluctuations, humidity changes and vibration shocks, ensuring the long-term reliability of critical components.

– Package for analog, power and dedicated function chips: Offers high stability and airtight protection, reduces temperature drift and noise, suitable for industrial, medical and research equipment.

In the aforementioned applications, the stability and long-term reliability of CSOP are usually more crucial than its size or the number of pins.

Relying on Innovacera’s mature ceramic molding and metallization processes, our CSOP package supports a variety of customization options: The size and number of pins can be customized according to customer requirements. The ceramic material can be either alumina or aluminum nitride. The metalization and surface coating schemes are flexible. The cover can be made of ceramic or metal for complete airtight protection.

Enquiry

Enquiry