As global oil and gas resource development continuously advances into deep, ultra-deep wells and complex geological environments, oilfield equipment is facing severe challenges of higher temperatures, higher pressures, and highly corrosive media. In this context, the reliability of key components has become an important foundation for ensuring the safe and stable operation of oil and gas exploration and production, and ceramic-metal welded parts provide reliable support.

1. What are ceramic-to-metal sealing components?

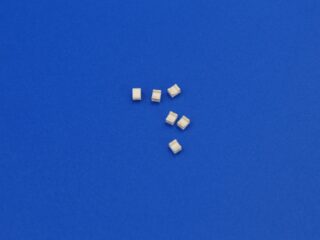

Ceramic-to-metal sealing components are functional structural parts that achieve metallurgical bonding between engineering ceramics and metal materials through the vacuum brazing process. This type of component possesses multiple functions such as electrical insulation, gas-tight sealing and mechanical bearing within the same structure. It is an important component of the electronic packaging and sealing systems in petroleum equipment.

Compared with traditional mechanical seals or adhesive methods, ceramic-metal welded components exhibit higher structural stability and operational reliability in high-temperature, high-pressure and highly corrosive environments.

2. Coordinated the selection design of ceramic and metal materials

In the application of the petroleum industry, ceramic-metal welded components are not merely a simple combination of materials, but are systematically designed based on the requirements of the working conditions.

Common ceramic materials include high-purity alumina (Al2O3) and silicon nitride (Si3N4). Among them, alumina ceramics possess excellent electrical insulation properties and airtightness, and are the most widely used materials in underground electrical connections and sensor packaging; silicon nitride ceramics have gradually been applied in high-end downhole tools and high-temperature structural components due to their high strength and excellent thermal stability.

The metal materials used in conjunction with ceramics are usually Kovar alloy, stainless steel or nickel-based high-temperature alloys. These metals not only possess excellent mechanical strength and pressure resistance, but also have a thermal expansion coefficient that can be matched with that of ceramic materials. This enables the effective reduction of internal stress at the welding interface under high temperatures and thermal cycles, thereby enhancing the long-term reliability of the overall structure.

3. The reliable sealing performance brought about by the vacuum brazing process

In terms of the connection process, the vacuum brazing technique is commonly used to achieve metallurgical bonding between ceramics and metals. This process achieves the metalization of the ceramic surface and the formation of a continuous and dense welding interface between the metal substrate and the metalized layer by introducing a specific solder in a high vacuum environment.

Compared with mechanical crimping or adhesive bonding methods, the welds formed by vacuum brazing have higher gas tightness and high-temperature resistance. They can remain stable in high-temperature, high-pressure and highly corrosive environments for a long time, and are less likely to leak or suffer structural failure. They are particularly suitable for applications in the petroleum industry where safety and reliability are of the utmost importance.

Relying on a mature ceramic material system and welding technology capabilities, Innovacera can provide customized services for ceramic-metal welded components using various ceramic materials. Meet the application needs of different industries for highly reliable sealing and packaging components under complex working conditions, providing reliable support for the safe and stable operation of high-end equipment in high-temperature, high-pressure and harsh environments. Please feel free to contact us at sale@innovacera.com.

Enquiry

Enquiry