In today’s era of rapid development in deep space exploration and satellite technology, efficient and reliable propulsion systems are the key to extending the lifespan of spacecraft and expanding the boundaries of missions. The Hall Effect Thruster (HET), as an advanced electric propulsion technology, has become the mainstay of modern satellite orbit maintenance and deep space missions due to its advantages of high specific impulse and long service life. However, its core component – the plasma chamber – has long been subjected to severe challenges such as high temperatures, high-energy ion sputtering, and strong electric fields, which directly limit the performance and reliability of the propulsion system.

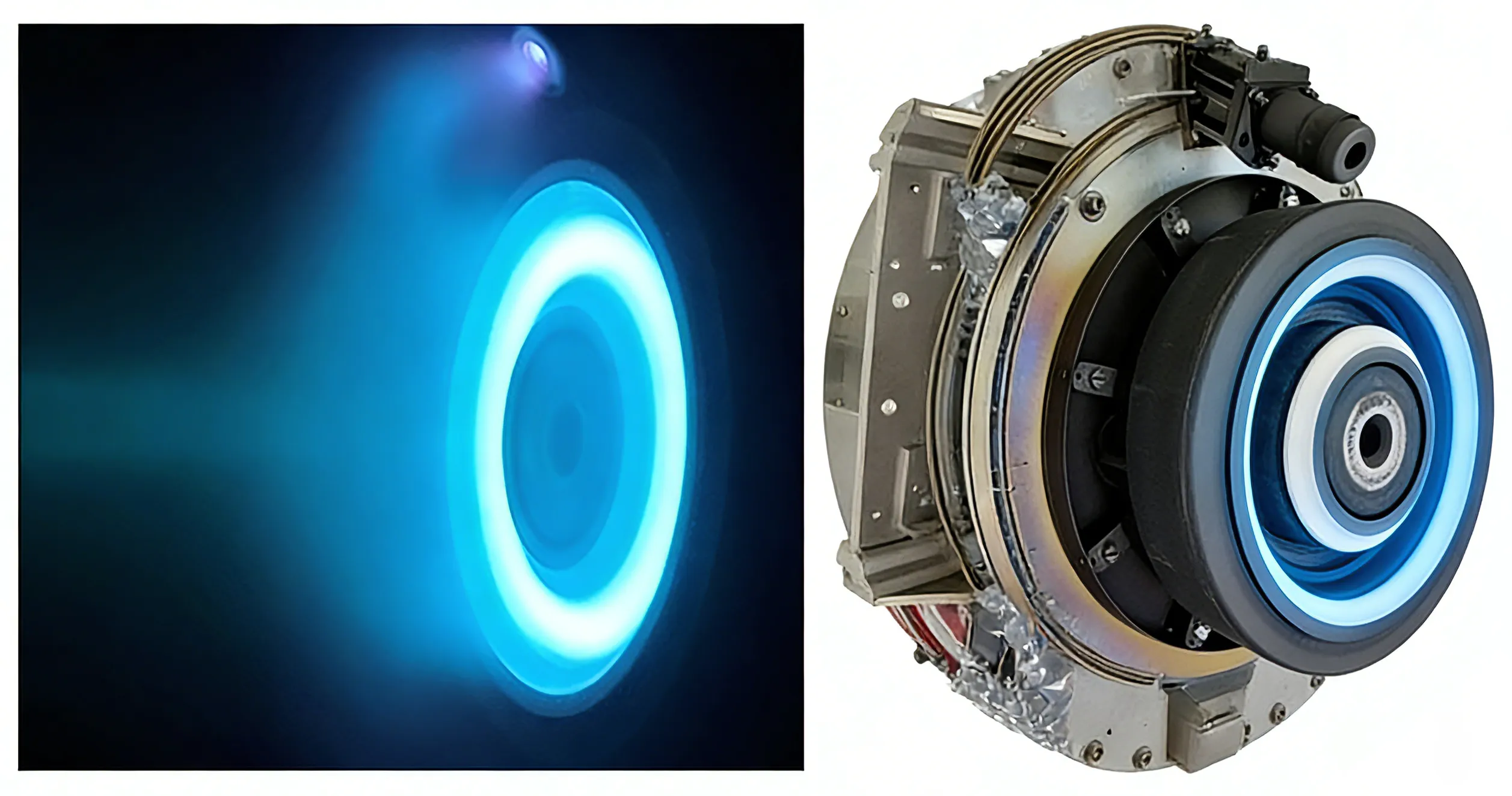

In this context, Innovacera has officially launched a hexagonal boron nitride (h-BN) plasma chamber component specifically designed for high-performance Hall effect thrusters. This component is made of advanced ceramic materials and employs precise manufacturing techniques, aiming to significantly enhance the operational efficiency, stability and service life of the thruster in extreme environments.

Breaking Through Material Limits: Why Choose Hexagonal Boron Nitride (h-BN)

The plasma chamber is the “heart” of the Hall thruster. It not only needs to confine and stabilize the plasma discharge and guide the ion flow to be ejected efficiently, but also must directly withstand the high-temperature heat load and high-speed ion bombardment from the plasma. Traditional materials can affect mission safety during long-term operation due to erosion, thermal stress, or degradation of electrical performance.

Hexagonal boron nitride (h-BN), a high-performance ceramic with a layered structure similar to that of graphite, possesses extremely high thermal stability, electrical insulation properties, and chemical corrosion resistance. It can bring revolutionary material advantages to Hall thrusters:

•High Temperature Resistance: Capable of enduring working conditions exceeding 1000℃ for an extended period, preventing structural failure due to uneven thermal expansion.

•Electrical insulation: Effectively prevents high-voltage breakdown and abnormal discharge, ensuring the stability of the acceleration electric field and the accuracy of thrust control.

•Resistance to ion erosion: Its surface is smooth and highly chemically inert, which can significantly delay the wear of the chamber wall and thus becomes a key factor in extending the lifespan of the propeller.

•Low secondary electron emission: This helps to reduce plasma disturbances and ensures stable and reliable thrust output.

Advantages of Innovative Design and Integration

The plasma chamber component of Innovacera is centered on high-purity h-BN material and is formed through advanced sintering technology and precise mechanical processing.

The product has the following features:

•Fine polishing of the inner surface of the chamber: Ensures uniform and smooth plasma flow, optimizing the efficiency of the thruster.

•Modular and customized design: The interface has been optimized, with strong compatibility. It can provide flexible sizes and complex geometries for quick customization based on the specific model and mission requirements of the customer’s thruster.

•Complete component solution: Offers pre-assembled high-integration cavity components that are ready for immediate use, simplifying the assembly process for customers and enhancing system reliability.

Empowering the next-generation propulsion system

The h-BN plasma chamber component launched this time is not only an upgrade in materials but also a comprehensive engineering innovation aimed at addressing the deep-seated needs of the electric propulsion system. This component effectively enhances the tolerance of the core components of the Hall effect thruster to extreme environments, meeting the strict requirements for high-performance and long-life thrusters. It can be widely applied to advanced space missions such as geosynchronous orbit satellites, large low-orbit constellations, and deep-space probes.

As a supplier of high-performance advanced material solutions, Innovacera has been dedicated to overcoming the challenges of high-end manufacturing through cutting-edge material science breakthroughs. The company’s products cover semiconductor, aerospace, medical equipment, and new energy fields, providing customized high-performance material support for industry customers. For more information about Innovacera products, please contact sales@innovacera.com.

Enquiry

Enquiry