The boron nitride evaporation boat (BN evaporation boat) is a high-temperature device made of high-purity hexagonal boron nitride ceramics. It is usually in a boat shape or custom-made, and can hold various evaporation materials. During use, it not only serves as a container for holding molten materials but also maintains the cleanliness and stability of the working environment. Unlike ordinary ceramic components, the BN evaporation boat possesses both structural strength and chemical inertness, and can be used stably for a long time under extreme conditions.

The comprehensive advantages of materials and techniques

(1) Core material: High-purity hexagonal boron nitride

Its purity is ensured not to have any impurities precipitate at high temperatures, fundamentally eliminating the pollution caused by the vessel, maintaining extremely high purity of the evaporated material, and ultimately achieving high-purity and high-performance thin film deposition. Therefore, it fully meets the strict requirements for film layer quality in high-precision industries such as semiconductors and optical coating.

Unreplaceable material performance advantages

h-BN is hailed as “white graphite”, possessing a variety of outstanding properties:

•High temperature resistance: Can be used stably in the air up to approximately 900℃, and can withstand temperatures above 2000℃ in vacuum or inert atmospheres.

•Chemical inertness: Does not react with most molten metals, semiconductor materials, glass, or chemical gases.

•Non-adhesive and non-wetting properties: The molten material forms beads on the BN surface, which are easily spilled or completely evaporated, leaving very little residue. The material utilization rate is high, and it is convenient for cleaning and maintenance.

•Thermal shock stability and insulation: Can withstand frequent thermal cycling while maintaining structural integrity; also an excellent high-temperature insulator, suitable for various heating methods.

Compared with graphite or metal evaporation vessels, BN evaporation vessels demonstrate significant overall advantages due to their unique chemical inertness and thermal stability. It not only withstands high temperatures and is resistant to corrosion, eliminating the risks of oxidation and contamination, but also significantly reduces material residue due to its non-wetting and non-adhesive surface. This improves the evaporation efficiency, extends the service life, and ensures the high stability and consistency of the process.

(2) Key Process: Vacuum Hot Press Sintering

This process can uniformly densify BN powder under high temperature and high pressure, thereby forming a microscopic structure with extremely stable physical properties. Its direct advantage lies in:

• Significantly enhance the bending strength and thermal shock resistance

• Extend service life and reduce replacement frequency

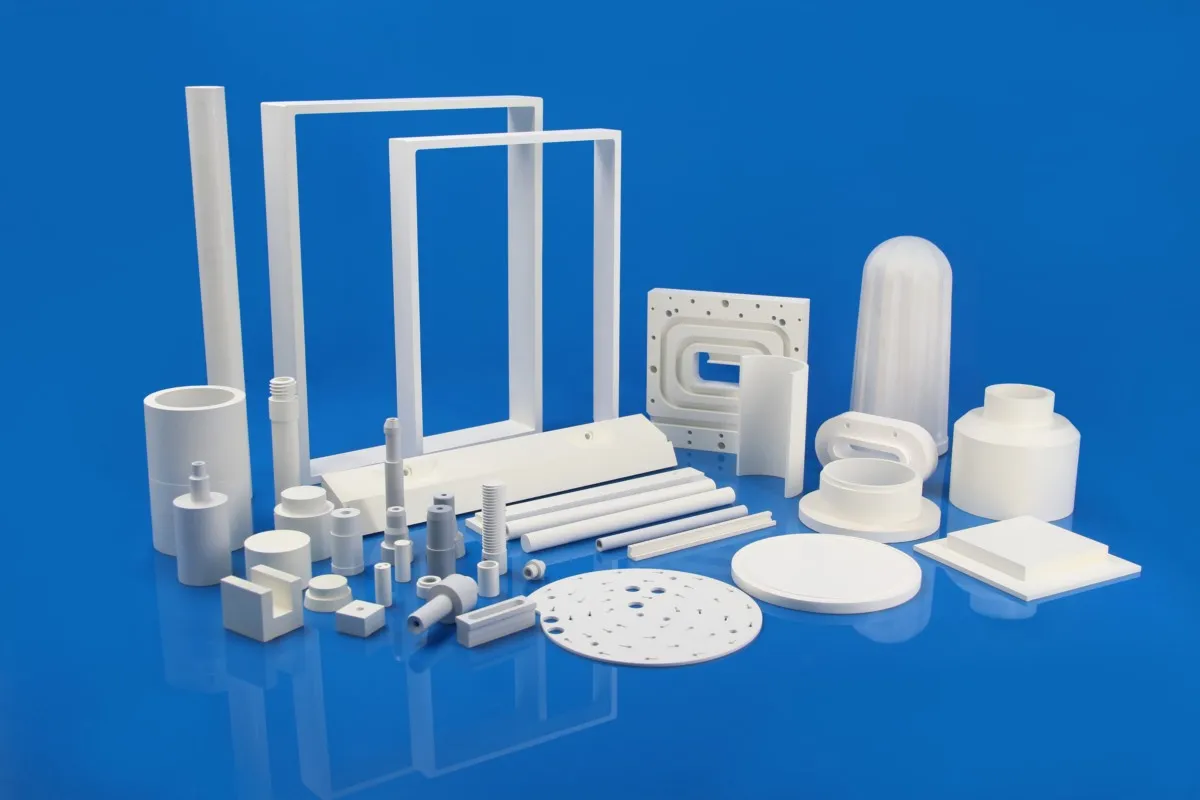

(3) Multi-form application, providing comprehensive solutions

Based on the excellent and universal performance of h-BN, it is not only fabricated into evaporation vessels, but also processed into various forms of high-temperature components, serving a wider range of fields:

• Ceramic rod: Used for stirring high-temperature molten materials.

• Ceramic plates, blocks, and crucibles: Used as high-temperature support platforms, sintering pads, or melting containers.

• Various customized components: such as high-temperature insulating isolation parts, pouring nozzles, protective sleeves, etc.

These products collectively offer a complete and reliable material solution for experiments and industrial environments that require high temperatures, chemical corrosion resistance, high purity, and electrical insulation.

The application scenarios of the BN evaporation boat

The core application of the BN evaporation boat is focused on areas that have extremely strict requirements for material purity, process stability, and equipment durability. These mainly include:

1. Semiconductor and Microelectronics Manufacturing

Key process: Vacuum evaporation deposition for components such as integrated circuits and sensors.

Specific application: evaporating high-purity metal interconnects (such as aluminum and gold), and functional film layers is a critical step in chip manufacturing.

2. Optical and Display Industry

Key process: Precise optical coating and conductive film preparation.

Specific applications: depositing anti-reflective, reflective, and other multi-layer optical films on lenses, lasers, and filters; preparing aluminum electrodes and ITO conductive films for display panels to ensure purity and uniformity of the film layers.

3. High-purity material research and special processing

Key process: Material synthesis and processing under high-temperature and high-purity conditions.

Specific applications:

Melting, evaporation and refining of metals and alloys (such as aluminum, gold, silver, chromium).

Purification and crystallization of high-purity substances under an inert atmosphere.

Used as an inert crucible or support piece for the high-temperature preparation of special glasses and crystals.

4. Surface Engineering and Functional Coatings

Key process: Decorative and functional surface coatings.

Specific application: On the surfaces of tools, consumer goods, etc., deposit protective, decorative, or functional special film layers.

With its numerous outstanding properties, the BN (boron nitride) evaporation boat plays an irreplaceable role in modern vacuum evaporation, thin film deposition, and semiconductor manufacturing processes. For process scenarios that require high reliability, high purity, and long lifespan, the BN evaporation boat is a mature and reliable engineering ceramic solution. Innovacera offers customized services for various specifications of BN evaporation vessels, which can meet the requirements of various high-temperature vacuum processes and provide customers with high-quality technical support and after-sales guarantees.

Enquiry

Enquiry