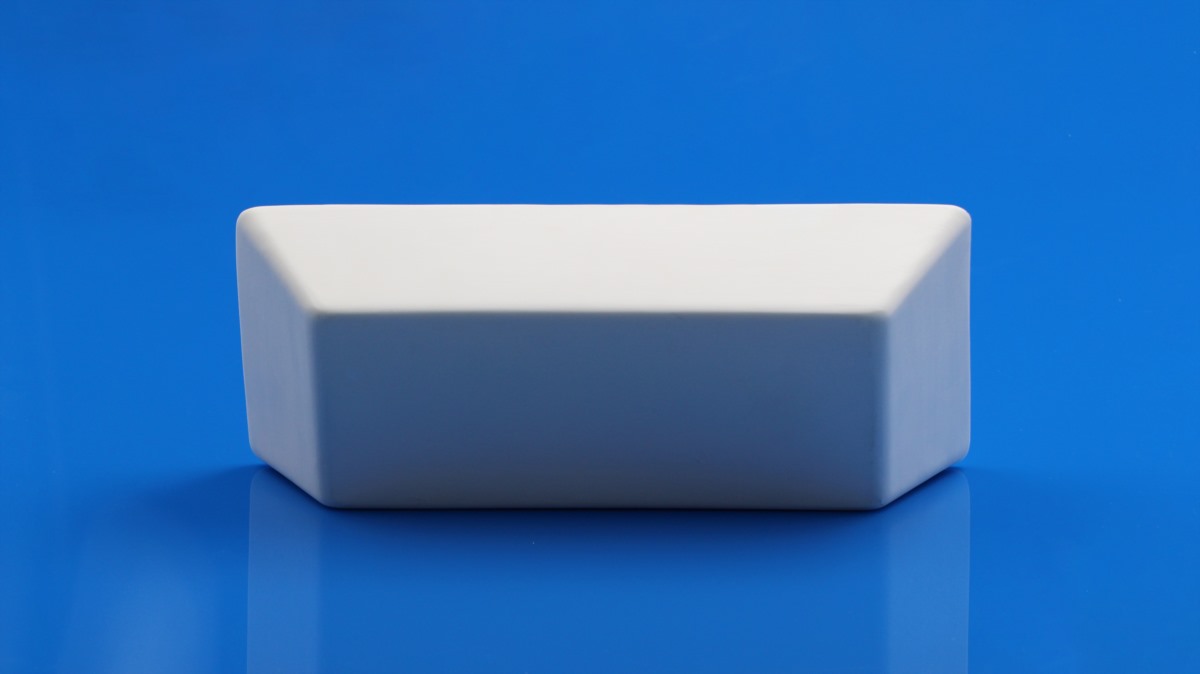

One Primary Use:Water-cooled crucible liner,Application as Crucible Liner for copper crucible,This high-purity alumina component is specifically engineered as a thermal insulation liner for water-cooled crucible systems in molten aluminum operations. Its primary function is to effectively isolate the corrosive from the crucible body, thereby serving the dual critical purposes of minimizing heat loss and providing exceptional resistance against aluminum penetration and erosion.

This set ensures enhanced process stability, energy efficiency, and prolonged crucible service life.

Advantage: It must provide excellent thermal insulation and withstand corrosion from molten aluminum.

Product Specifications

a.Material: 99% Alumina

b.Size: 296*126*58 mm

c.Tolerances: Wall thickness ±8 mm, width & height ±2 mm, length ±4 mm

d.Customization: Yes

e.Mold Required: No

f.MOQ: None (orders can start from 1 unit)

g.Product Model Number: SS0483B059V00

Performance Data

Thermal Properties:

a.Maximum heat resistance of the alumina crucible-up to 1730°C.

b.Heating rate should not exceed 5°C per minute, and the temperature rise should not exceed 300°C per hour.

99 Alumina Ceramic Material Properties-SU0207

| Properties | Unit | Value |

| Main Composition | % | 99 |

| Density | g/cm3 | ≥3.88 |

| Hardness | HRA | 88.00 |

| Flexural Strength | MPa | ≥350 |

| Compressive Strength | MPa | ≥2,500.00 |

| Young Modulus | GPa | 350.00 |

| Max Using Temperature | °C | 1,500.00 |

| Thermal Expansion Coefficient (20-1000°C) | 10-6/°C | 8.20 |

| Thermal Conductivity (20°C) | W/(m.k) | 25.00 |

| Electrical Resistivity (20°C) | Ω·cm | ≥ 1014 |

| Dielectric Strength | KV/mm, DC | 20.00 |

| Dielectric Constant (20°C,1MHz) | εr | 9.40 |

| Dielectric Loss (1MHz) | tanδ × 10-4 | 2.00 |

Enquiry

Enquiry