As optical communication, LiDAR, and high-precision optoelectronic detection systems evolve toward higher power and greater integration density, they place higher demands on the performance of optoelectronic packaging materials. The increase in device power brings challenges in heat dissipation and high-temperature stability, while the improvement in integration density raises the risks of internal stray light interference and electrostatic discharge (ESD), directly affecting system reliability and signal-to-noise ratio. Traditional white alumina has limitations in optical control, and conventional ESD protection solutions often fail to be perfectly compatible with high gas-tightness and high thermal conductivity packaging systems.

Based on the high mechanical strength, thermal conductivity, and excellent insulation properties of black alumina ceramics, the material achieves a multi-functional integration of optical control, thermal management, and on-chip electrostatic discharge (ESD) protection.

1. Anti-static capability: Material-level ESD protection

Black alumina ceramics achieve this controlled resistivity by precisely doping transition metal ions (such as manganese, titanium, and cobalt) at the boundaries of the alumina grains, thereby forming a microscopic conductive network within the material. As a result, the volume resistivity of the material can be controlled within the range of 10⁶ – 10¹¹ Ω·cm.

This design enables the electrostatic charges to be released at a controlled and gradual rate, preventing damage to the laser or photodetector chips due to instantaneous discharge, while also not affecting the signal integrity. Compared with applying anti-static coatings or conductive fillers on the surface, the intrinsic conductive properties of black alumina ceramics

2. Optical Control and Thermal Management: The Comprehensive Advantages of Black Ceramics

Black alumina ceramics achieve high absorption rates for visible light and near-infrared light through ion doping, which can increase the absorption rate of internal stray light in the package to over 95%. This effectively reduces optical crosstalk and noise, providing a stable optical environment for high-speed optical communication modules and precise photodetectors.

Meanwhile, it inherits the high mechanical strength and high thermal conductivity (approximately 24–28 W/(m·K)) of white alumina ceramics. It efficiently dissipates heat from the device, maintaining dimensional stability and performance under high-power, high-temperature conditions, ensuring long-term reliable operation.

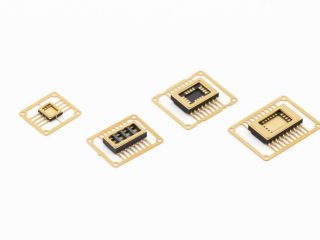

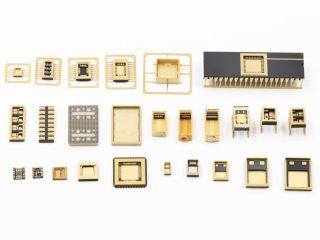

3. Multi-functional Integrated Application Cases

(1)High-Power Laser Module Packaging

• Black alumina ceramic can be used as a tube shell or heat sink, efficiently conducting the heat from the chip.

• The black ceramic body absorbs reflected light, reducing optical interference.

• Its ESD control properties protect the chips during mounting and wire bonding.

(2)Avalanche Photodiode (APD) Packaging

APD is highly sensitive to static electricity. Black alumina ceramic, when used as a tube base or window plate, can provide physical support, optical isolation, thermal management and static shielding, significantly enhancing the component’s surge resistance and operational lifetime.

(3)Microwave Optoelectronic Integrated Modules

• The module integrates a laser, a driving circuit and a radio frequency transmission line. The electromagnetic environment is complex.

• The black alumina ceramic substrate combines microwave transmission performance, electrostatic discharge prevention function and optical signal isolation, achieving the integration of a multi-functional substrate.

The multi-functional integration characteristics of black alumina ceramics signify the evolution of photonic packaging materials from passive protection to active functional design. It has been optimized through materials science, integrating optical control, thermal management and anti-static functions, providing a system-level reliability solution for high-power and high-integration optoelectronic devices.

For photonic systems that aim for high performance and ultra-high reliability, choosing black alumina ceramics is not just selecting a packaging material—it represents a system-level high-reliability strategy. Innovacera provides customized solutions for ceramic packages using black alumina ceramics—contact sales@innovacera.com

to learn more.

Enquiry

Enquiry