Currently, electronic products are evolving rapidly towards high power, high integration, and high reliability. The limitations of traditional organic substrates in terms of heat dissipation bottlenecks, high-temperature tolerance and long-term stability are becoming increasingly prominent, and have become a key challenge for industrial upgrading.

In this context, high-performance ceramic substrates, as the core material of ceramic printed circuit boards (ceramic PCB), have become a strategic choice to overcome these bottlenecks and advance power electronics, RF communication, and advanced packaging.

Innovacera, as a manufacturer specializing in advanced ceramic materials, has always been committed to research and development as well as the precise manufacturing of high-performance ceramic substrates. We provide stable, reliable materials and comprehensive support for ceramic PCBs and other high-reliability electronic applications.

Why Ceramic Substrates Are Key to Ceramic PCBs

The overall performance of ceramic PCBs largely depends on the substrate material they use. Compared to traditional organic substrates such as FR-4(Glass Reinforced Epoxy, G10/FR-4), ceramic substrates have significant advantages in several key performance aspects.

1. Excellent heat dissipation capability

Ceramic materials, particularly alumina (Al2O3) and aluminum nitride (AlN), have excellent thermal conductivity, efficiently dissipating heat during operation, reducing junction temperatures, and improving system stability. This characteristic makes it particularly important in power devices and high-power modules.

2. Stable and reliable electrical performance

The ceramic substrate possesses excellent insulation properties and dielectric stability, and can still operate reliably under high voltage and high-frequency conditions. It is an important foundation for the application of ceramic PCBs in the fields of power electronics and radio frequency.

3. Excellent high-temperature resistance and aging resistance properties

Ceramic materials can operate stably at high temperatures for a long time without aging or deforming. They are suitable for use in highly reliable automotive electronics, industrial control, and new energy systems.

4. Excellent dimensional stability

The ceramic substrate offers low thermal expansion and structural stability, meeting the demands of high-precision circuits and high-reliability packaging. It serves as an ideal substrate material for high-end ceramic PCBs.

The crucial role of ceramic substrates in ceramic PCBs

From a structural perspective, ceramic PCBs are essentially circuit systems constructed with ceramic substrates as the core carrier.

The performance of the substrate directly determines the heat dissipation capacity, electrical performance and service life of the entire circuit board.

At present, ceramic substrates have been widely applied in the following ceramic PCBs and related structures:

·DBC (Direct Bonded Copper) substrate

·AMB (Active Metal Brazing) substrate

·thick film / thin film ceramic circuit

·high power LED module

·IGBT and power module packaging

It can be said that high-performance ceramic substrates are the key foundation for achieving highly reliable ceramic PCBs.

Innovacera Ceramic Substrate Solution

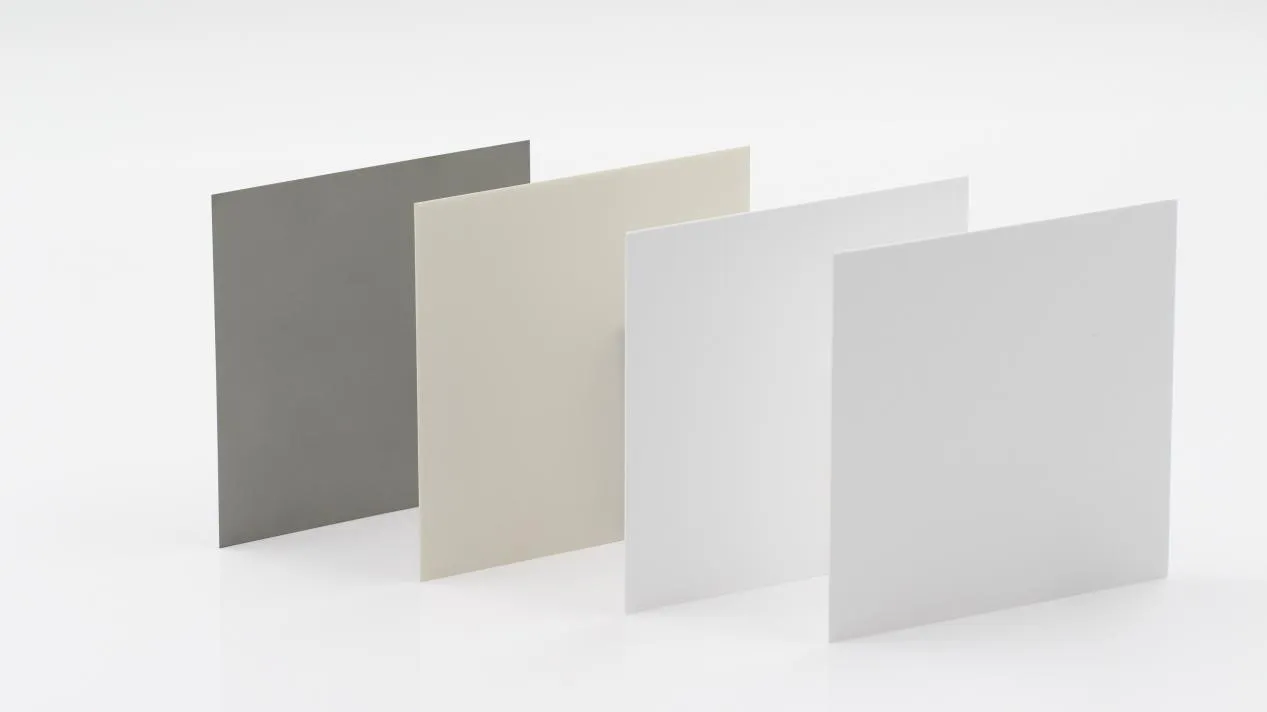

With proven materials and stable manufacturing processes, Innovacera offers a wide range of high-performance ceramic substrates for diverse applications.

■ Alumina (Al2O3) ceramic substrate

Stable performance, high cost-effectiveness, widely used in electronic packaging, LED modules, and general power devices.

■ Aluminum nitride (AlN) ceramic substrate

It has excellent heat-conducting properties and is suitable for high-power density applications, such as power modules, communication equipment and new energy systems.

■ Silicon nitride (Si3N4) ceramic substrate

It combines high strength and high reliability, and is suitable for application environments with high requirements for mechanical properties and thermal shock.

■ ZTA (zirconia-reinforced alumina) ceramic substrate

While maintaining the excellent insulation properties of alumina, the introduction of zirconia phase significantly enhances fracture toughness and impact resistance, suitable for electronic and industrial applications that demand high mechanical toughness, wear resistance, and structural reliability.

Meanwhile, Innovacera can provide customized ceramic substrates of various sizes, thicknesses and surface treatment methods according to customer requirements, providing a reliable foundation for the subsequent ceramic PCB manufacturing and packaging processes.

A reliable choice for high-end electronic applications

With the rapid development of new energy, 5G communication, power semiconductors and high-end equipment manufacturing, the market demand for high-performance ceramic substrates continues to increase.

As the core material of ceramic PCBs, ceramic substrates play an increasingly important role.

Backed by proven material systems, mature manufacturing processes, and extensive application experience, Innovacera delivers high-quality ceramic substrate solutions to support the reliability and performance of next-generation electronics.

Enquiry

Enquiry