Hexagonal boron nitride is an excellent self-lubricating ceramic capable of withstanding extremely high temperatures while maintaining its lubricating properties, even in high-vacuum environments. Boron nitride (BN) crucibles are typically manufactured from hot-pressed boron nitride blanks, ensuring high density and structural integrity. Mechanically, hexagonal boron nitride behaves similarly to graphite, but it offers the additional advantage of outstanding electrical insulation.

Compared with graphite crucibles, BN crucibles exhibit significantly lower risk of carbon contamination and demonstrate greater chemical inertness in many high-temperature processes. In comparison with alumina crucibles, BN crucibles show lower wettability to molten metals, making them especially suitable for applications that demand high purity and minimal interaction between the melt and the container. While different crucible materials are optimized for different process conditions, the appropriate selection should always be based on specific operational requirements.

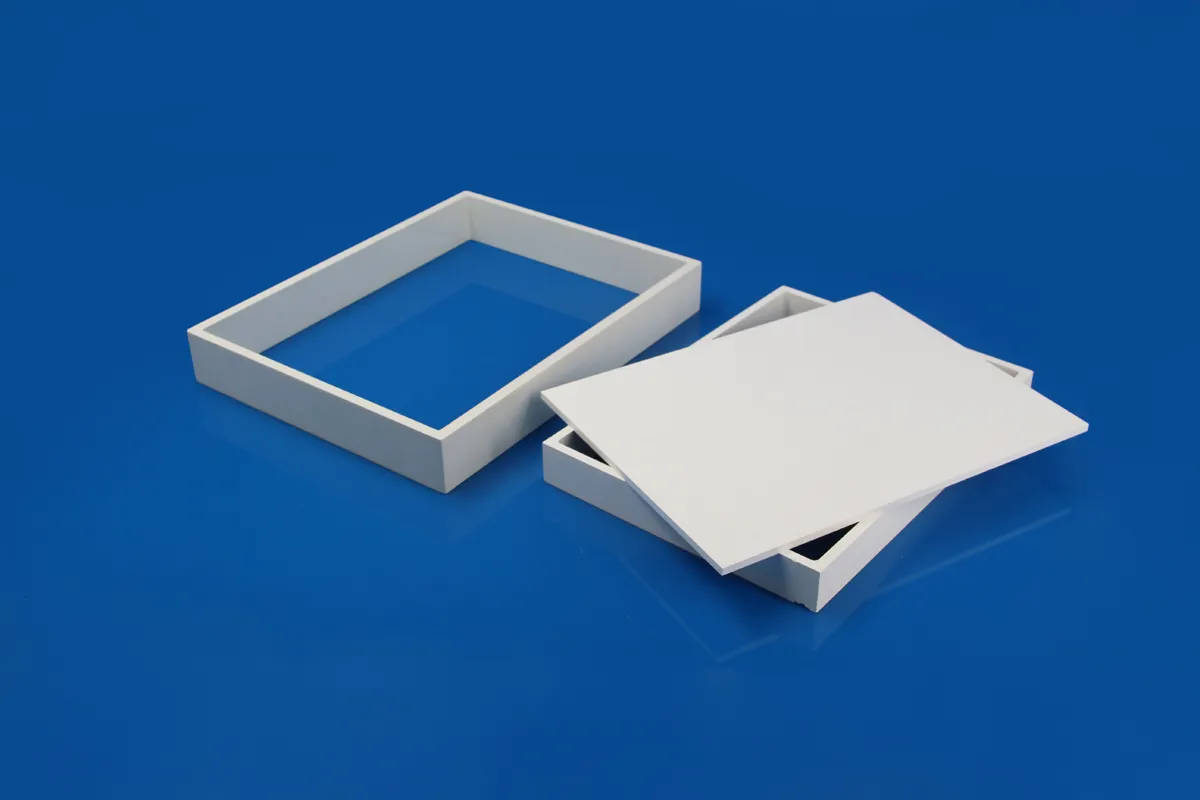

BN crucibles are well known for their ability to withstand high temperatures under high-vacuum conditions. In addition, they offer excellent corrosion resistance, thermal stability, and electrical insulation. These properties make boron nitride crucibles an ideal solution for a wide range of advanced industrial and research applications, including:

Crucibles for crystal growth

Laboratory-scale high-temperature synthesis and crystal growth

Semiconductor manufacturing and high-purity metal processing

Vacuum or inert-atmosphere melting of metals and specialty alloys

Sintering and melting of alloys, ceramics, rare earth materials, and other advanced materials

With the continuous advancement of high-temperature processing and high-purity material preparation technologies, the application potential of boron nitride crucibles is steadily expanding. Their role in advanced ceramics, semiconductor fabrication, and emerging functional materials is becoming increasingly significant. Looking ahead, BN crucibles are expected to see broader adoption in more demanding environments involving complex operating conditions and even stricter purity requirements.

Enquiry

Enquiry