The components are specially designed for high vacuum, ultra-high vacuum and harsh working conditions. They can operate stably under extreme temperature shocks, mechanical stresses and long-term baking. They are the key core components for achieving signal transmission, power input or sensor output in vacuum equipment.

It is widely used in high-end scientific research and industrial equipment fields such as mass spectrometry analysis, CT tubes, ceramic core columns, electron microscopes, particle accelerators, vacuum metallurgy, semiconductor coating, and spacecraft simulation cabins.

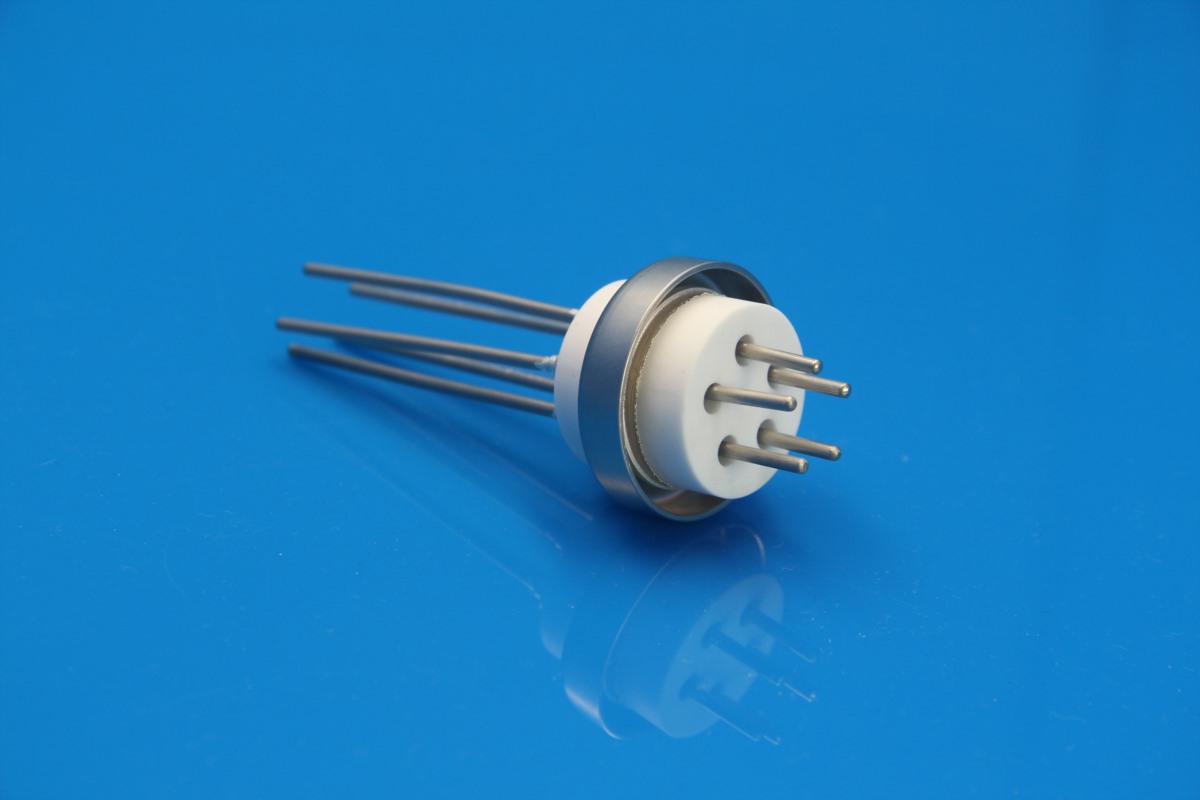

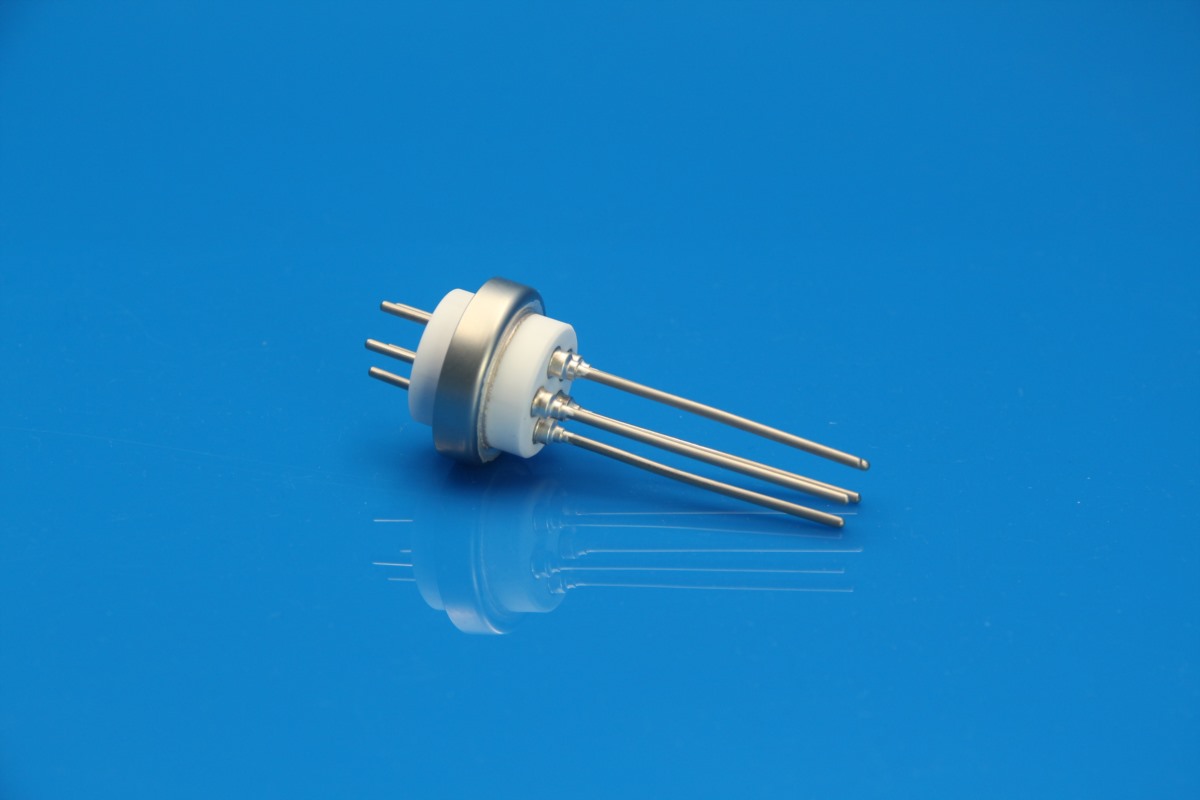

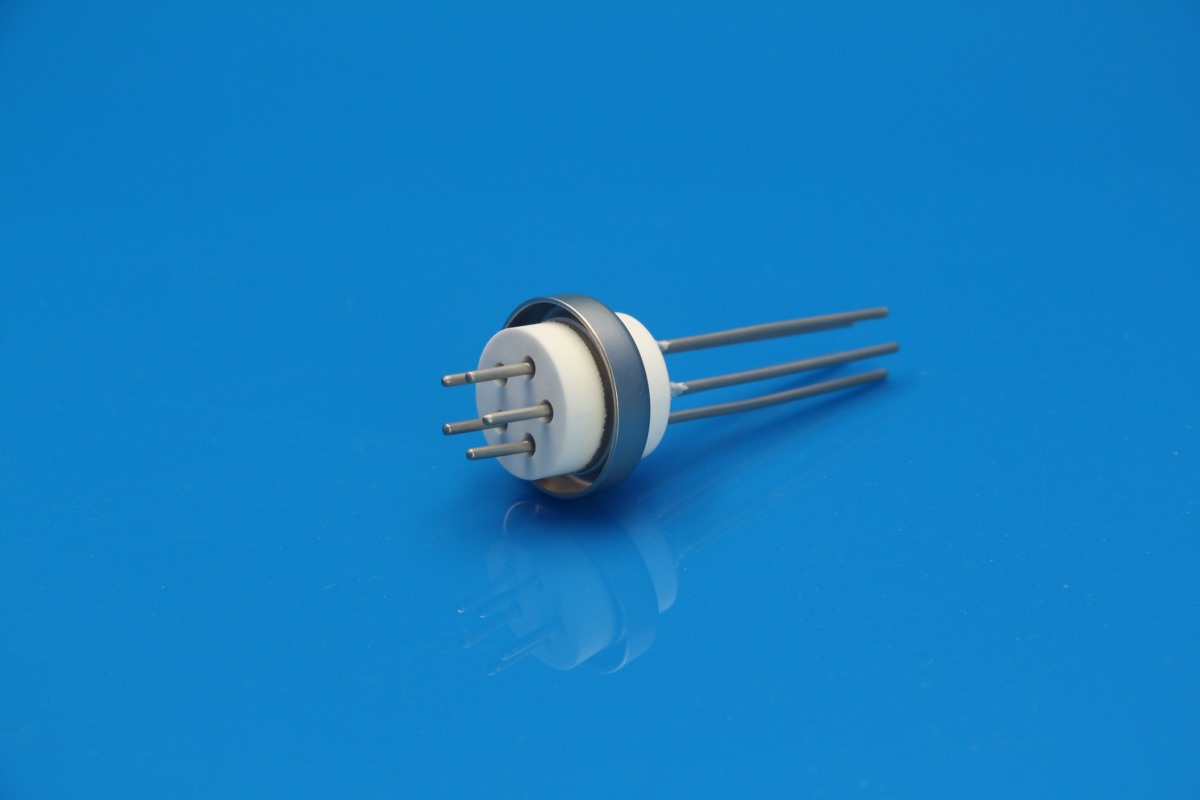

Structure and Materials

– Ceramic insulator:High-purity alumina ceramic, featuring excellent electrical insulation, high-temperature resistance and chemical stability

– Metal pins / rods:Stainless steel, molybdenum, Kovar or nickel-based alloys (optional), meeting different thermal expansion matching requirements

– Sealing method:Vacuum brazing (metal-ceramic eutectic brazing), forming a permanent gas-sealed connection

– Structural form:Multi-pin design (2-pin / 3-pin / 4-pin and custom), axial or flange-type structure options available

Advantage:

– Excellent vacuum sealing performance

– Strong resistance to high temperatures and thermal cycling

– High insulation properties

– Long-term reliability

– Highly customizable

Typical Application

– Vacuum furnaces and high-temperature vacuum heating systems

– Vacuum coating and plasma equipment

– Semiconductor and research vacuum devices

– High vacuum sensors and electro-vacuum components

Technical Specifications:

| Item | Specification |

| Ceramic Material | ≥95% Alumina |

| Sealing Process | High-temperature vacuum brazing |

| Operating Vacuum | High vacuum / Ultra-high vacuum |

| Leak Rate | ≤10⁻⁹ mbar·L/s |

| Operating Temperature | Up to 300–800°C (structure-dependent) |

| Pin Count | 1–4 pins (customizable) |

| Insulation Resistance | ≥10⁹ Ω |

| Mounting Type | Flange / Feedthrough / Custom |

This brazed ceramic vacuum welding component has been designed with full consideration of thermal expansion matching, stress release and vacuum reliability. It can significantly reduce the risk of system leakage and improve the long-term stability and consistency of the entire machine. It is an indispensable key basic component in high-reliability vacuum systems.

Enquiry

Enquiry