![]()

Features

- High thermal conductivity

- Thermal expansion coefficient close to silicon wafer

- High strength and toughness

Application

- High power IGBT power module

- High power heat sink

- Wireless module

Material Properties Table

| Project | Test conditions | Unit | Si₃N₄ | |

| SN-90 | ||||

| Material | – | – | Si₃N₄ | |

| Appearance | – | – | grey | |

| Surface roughness | Ra | μm | 0.2~0.75 | |

| Density | – | g/cm 3 | ≥3.2 | |

| Physical properties | Bending strength | 3 -point bending resistance | MPa | ≥750 |

| Vickers hardness | Load 4.9 | GPa | ≥14 | |

| Water absorption | – | % | 0 | |

| Thermal performance | Thermal conductivity | 25℃ | W/(m·k) | ≥85 |

| Linear thermal expansion coefficient | 25-500℃ | x10 -6 mm/℃ | 2~4 | |

| Thermal shock resistance | 800℃ | Time | ≥10 | |

| Specific heat | – | J/(kg·K) | 680 | |

| Electrical properties | Dielectric constant | 1MHz/25℃ | – | 7~8 |

| Dielectric loss | 1MHz/25℃ | x10 -4 | ≤4 | |

| Volume resistivity | 25℃ | Ω·cm | > 10 14 | |

| Breakdown voltage | – | kV/mm | > 15 | |

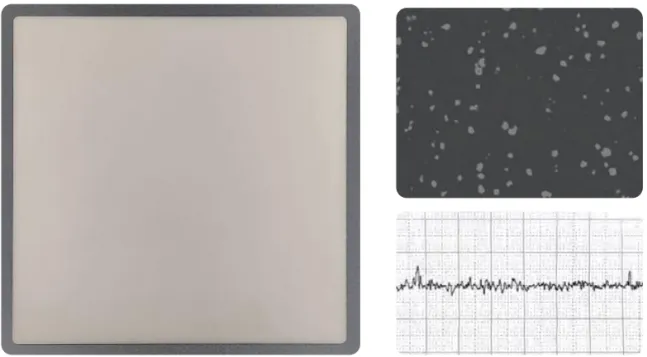

| Light performance | Reflectivity | Reflectivity meter | – | – |

| Whiteness | Whiteness meter | – | – | |

Specifications and Dimensions

| Material | Unit | Al₂O₃ | ZTA | AlN | Si₃N₄ |

| Effective dimensions ( A , B ) | mm | 50.8-190 | 50.8-190 | 50.8-190 | 138*190 |

| Thickness ( T ) | mm | 0.25-1.5 | 0.25-1.5 | 0.25-1.0 | 0.25 , 0.32 |

| Thickness tolerance | mm | ±5% ( Min±0.03mm ) | ±5% ( Min±0.03mm ) | ±5% ( Min±0.03mm ) | ±5% ( Min ±0.03mm ) |

| Warpage ( C ) | mm | ≤0.3% | ≤0.3% | ≤0.3% | ≤0.3% |

| surface roughness | μm | 0.2-0.6 | 0.2-0.5 | 0.2-0.75 | 0.2-0.75 |

| Size, thickness and surface roughness can be customized | |||||

Processing

• Laser processing

• Grinding and polishing sheet roughness table

| Project | Qualified | Special Grade | ||

| Internal dimension tolerance | ±0.05mm | ±0.03mm | ||

| External dimension tolerance | ±0.15mm | ±0.1mm | ||

| Hole tolerance (φ0.07-0.15mm) | ±0.05mm | ±0.02mm | ||

| Hole tolerance (φ > 0.15mm) | ±0.1mm | ±0.02mm | ||

| Project | Surface roughness (μm ) | |||

| Qualified | Special Grade | |||

| Grinding | 0.3-0.6 | 0.3-0.5 | ||

| Fine grinding | 0.1-0.4 | 0.1-0.3 | ||

| Polishing | ≤0.1 | ≤0.05 | ||

Enquiry

Enquiry