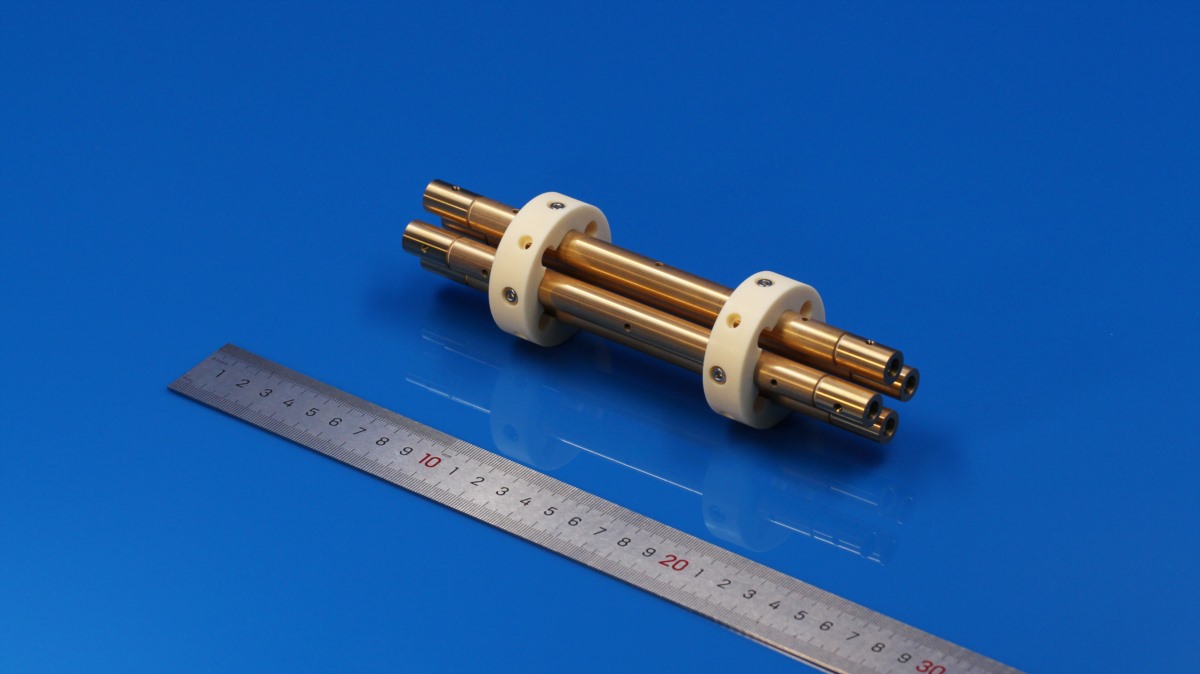

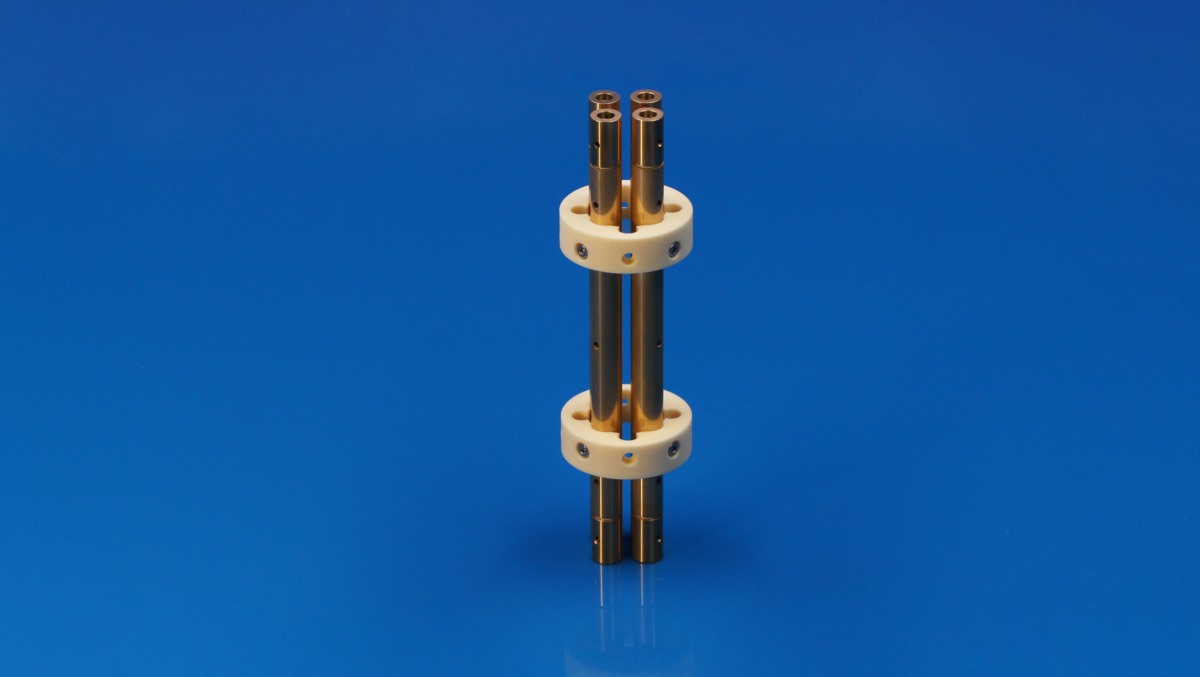

Structural Parameter Table:

| Structural | Value |

| Material Options | Ceramic plated Gold/Stainless Steel/Molybdenum |

| Rod diameter | 2-16mm |

| Rod Length | 100-300mm |

| Base | Alumina Ceramic/Machinable Glass Ceramic |

| Comprehensive accuracy | ≤3μm |

99% Alumina Ceramic Material Properties

| Type | Unit | Standard | Value |

| Color | – | – | Ivory |

| Main Characteristics | – | – | Excellent plasma corrosion resistance, high wear resistance. |

| Application Field | – | – | Semiconductor equipment components, wear-resistant and corrosion-resistant parts. |

| Density | g/cm3 | ISO18754:2003 | 3.88 |

| Water Imbibition | % | – | 0 |

| Vickers Hardness | HV | ASTM-C1327-15 | 17 |

| Bending Strength | MPa | ASTM-C1161-13 | 350 |

| Compressive Strength | MPa | GB/T8489-2006 | 2450 |

| Young’s Modulus | GPa | ASTM-C1198-09 | 350 |

| Poisson’s Ratio | – | ASTM-C1421-18 | 0.22 |

| Fracture Toughness | MPa·m1/2 | ASTM-C1421-18 | 4-5 |

| Linear Coefficient of Expansion (40-400°C) | x10-6/°C | ASTM-E1461-13 | 8.2 |

| Thermal Conductivity (20°C) | W/(m·k) | ASTM-E1461-13 | 25-30 |

| Specific Heat | J/(kg·k)x103 | ASTM-E1461-13 | 0.8 |

| Volume Resistivity (20°C) | Ω·cm | – | >1015 |

| Dielectric Strength | KV/mm | – | 20 |

| Dielectric Constant | – | ASTM-D2149-13 | 9.2 |

| Dielectric Loss Coefficient | x10-4 | ASTM-D2149-13 | 2 |

| Nitric Acid (HNO3) (90°C) | Weight Loss | – | <0.12 |

| Sulfuric Acid (H2SO4) (95°C) | – | <0.3 | |

| Sodium Hydroxide (NaOH) (80°C) | – | <0.9 | |

| Max Using Temperature | °C | – | 1500 |

Benefits:

- Custom Specifications

- Superior Surface Treatment Technology

- High Accuracy Installation, 3um Comprehensive Tolerance

- Consistent Process Management

- High-Purity Alumina Ceramic Collars

- High-Quality Chamber and Accessory Integration

Enquiry

Enquiry