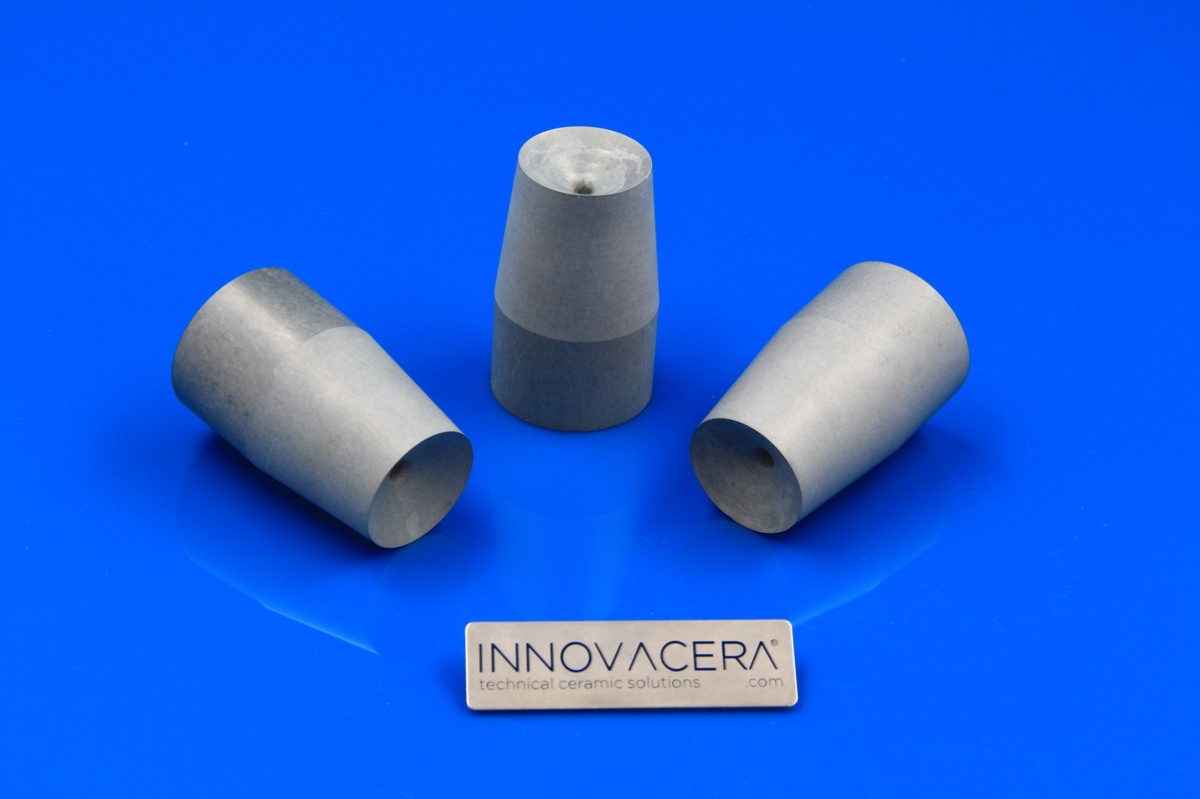

BN is a hot-pressed hexagonal boron nitride with a unique combination of chemical, electrical, mechanical and thermal properties. It is suitable for a range of applications where high performance is required. BN ceramic nozzle is used in various high-temperature and high-performance industry like aerospace and semiconductor, which has gained much attention in recent years due to its unique properties below:

1.Exceptional Thermal Stability

With melting point of approximately 2900°C, BN ceramic nozzle can be used for temperature 1800 °C and 2100°C separately in high vacuum and inactive gas environment.

2.Thermal Shock Resistance

BN nozzles can withstand rapid temperature changes without cracking. So it can be used in environments with dramatic temperature fluctuations dramatically.

3.Extreme Corrosion Resistance

Boron Nitride ceramic has high resistance to chemical corrosion like acids and alkalis. It can protect the nozzle from the materials it handles to reduce the risk of contamination and extend lifespan.

4.Self-lubricating

BN material is self-lubricating. It can make sure molten materials do not adhere to the nozzle, preventing clogging and ensuring smooth material flow.

5.Electrical Insulation

BN is an excellent electrical insulator, so it is suitable for applications like high voltages or plasma.

Material Property

| Material Composition | BN+ZrO2 | 99 BN |

| Density | 2.8–2.9 g/cm³ | 2.0 g/cm³ |

| Color | White Graphite | White |

| Bending Strength | 90MPa | 35MPa |

| Compressive Strength | 220MPa | 85MPa |

| Thermal Conductivity | 30 W/(m.k) | 40 W/(m.k) |

| Thermal Expansion Coefficient (20-1000°C) | 3.5 10-6/K | 1.8 10-6/K |

| Max working temperature | In Inert Gas 1800 °C | In Inert Gas 2100 °C |

| In High Vacuum 1800 °C | In High Vacuum 1800 °C | |

| In Atmosphere 900 °C | In Atmosphere 900 °C |

With properties of exceptional thermal stability, excellent thermal shock resistance, outstanding electrical insulation, chemical inertness and lubricity, we have developed a serious of new product metal and glass processing nozzle, nozzle for 3D printing and semiconductor and aerospace industry.

1.Metal and Glass Processing

BN nozzle is widely used in metal casting and glass manufacturing, where it is exposed to molten metals and glass in high temperature. BN’s high wet resistance to molten metals and glass, its chemical inertness guarantees smooth flow and prevent clogging. If you are looking for metal and glass processing nozzle, BN will be a good choice.

2.3D Printing

In metal 3D printing, BN nozzles are used to deliver powdered materials or molten metals. Its thermal stability and low friction properties make sure consistent material flow, reducing wear and tear of equipment and improving print quality.

3.Semiconductor Industry

In semiconductor industry, BN nozzles used in chemical vapor deposition (CVD) and some high-temperature processes. It is suitable to handle reactive gases and ensure precise deposition as it won’t produce chemical reaction even under extreme conditions.

4.Aerospace Industry

BN nozzle is used in rocket engines and thrusters. It has the ability to withstand extreme temperatures and resist thermal shock, which makes it an ideal use for directing high-velocity exhaust gases.

The BN nozzle’s applications in metal and glass processing, 3D printing, Semiconductor and aerospace demonstrate its versatility and reliability. With its numerous advantages, BN nozzle continues to be a preferred choice for high-performance applications. Any more question about BN nozzles just feel free to contact us at +86 592 558 9730 or sales@innovacera.com for more information.

Enquiry

Enquiry