As China pushes for self-sufficiency in semiconductor technology, domestic manufacturers are striving to produce advanced ceramic heaters. Ceramic heaters are critical components in chip-making equipment. They ensure precise temperature control during key semiconductor manufacturing processes, making them indispensable in modern fabs.

Why Ceramic Heaters Matter in Semiconductor Manufacturing?

In semiconductor production, wafers undergo processes such as thin-film deposition (CVD, PECVD, ALD) and etching, which require extremely precise and uniform heating. Traditional metal heaters face limitations at high temperatures (above 500 °C) due to thermal expansion and risks of particle contamination.

Performance Comparison: Aluminum Nitride (AlN) Heaters vs. Aluminum Heaters

| No | Item | Al Heater | AIN Heater |

| 1 | Operation Temp | R.T ~ 450 °C (Max) | R.T~800℃ |

| 2 | Melting Point | 660.25℃ | 1800 °C (Sintering Temp.) |

| 3 | Thermal Conductivity | 230 W/m·K | 170–220 W/m·K |

| 4 | Coefficient of Thermal Expansion | 23.6 × 10⁻⁶ /°C | 4.03 × 10⁻⁶ /°C |

Advantages of Ceramic Heaters

Ceramic heaters made from aluminum nitride (AlN), silicon nitride (Si₃N₄), or alumina (Al₂O₃) offer superior performance:

-High thermal conductivity, ensuring uniform heat distribution across wafers.

-Excellent plasma resistance, allowing them to withstand harsh semiconductor processing environments.

-Low thermal expansion, preventing warping and ensuring stability for nanometer-scale chip fabrication.

Preparation Process of Ceramic Heaters

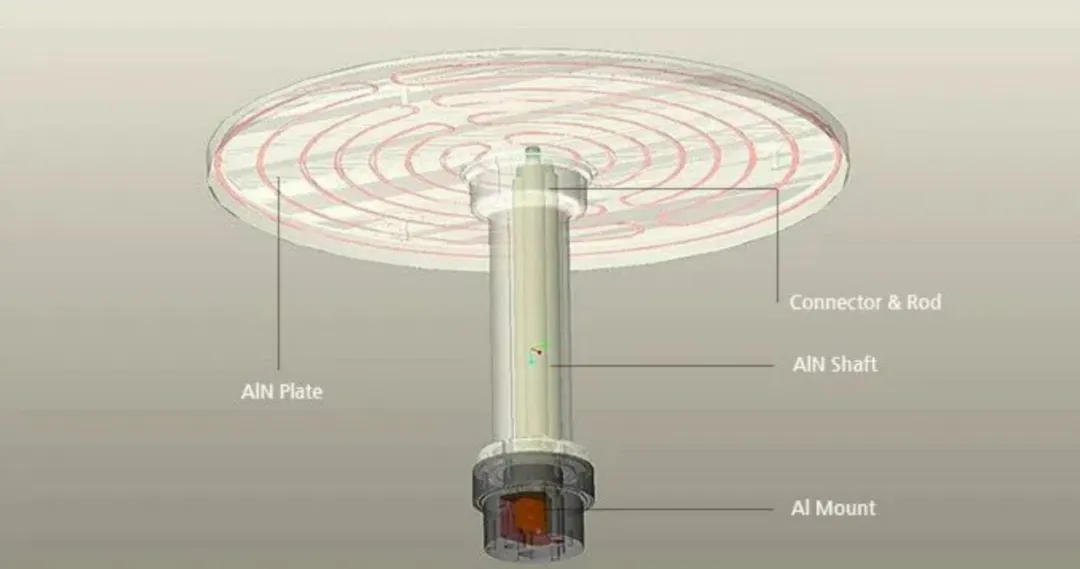

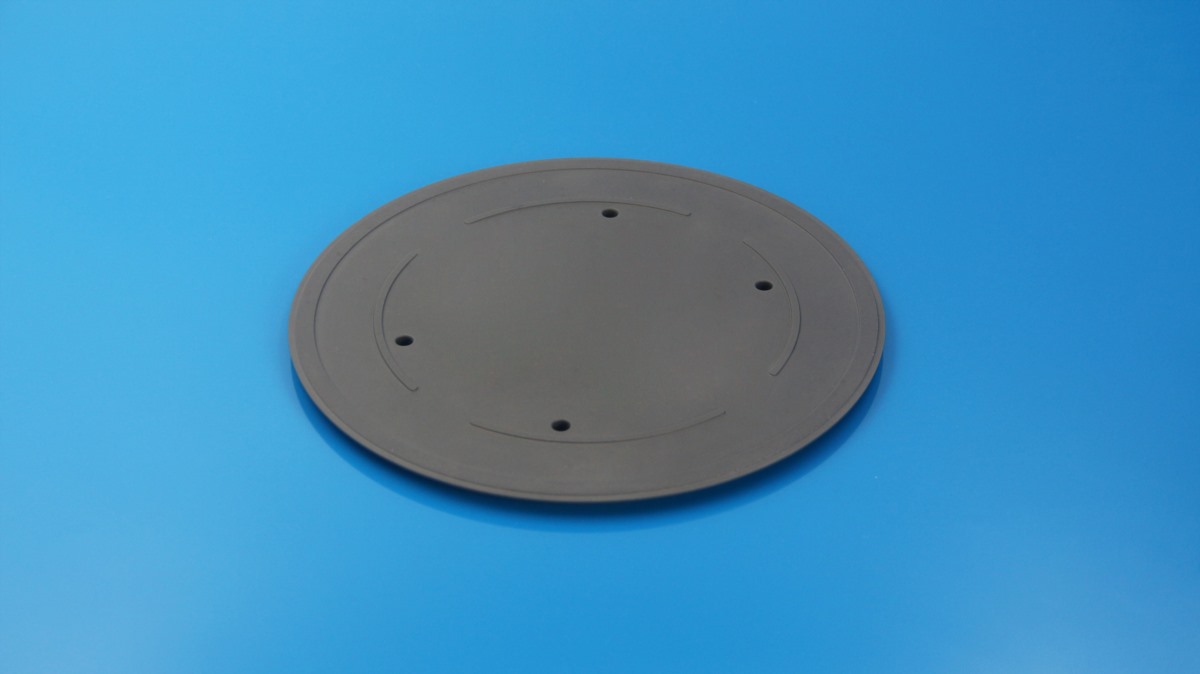

Typically, a ceramic heater consists of a ceramic substrate with a wafer-loading surface and a cylindrical support body on the back. Embedded within or printed on the ceramic substrate are resistance heating circuits, along with conductive elements such as RF electrodes and electrostatic chuck electrodes.

According to Patent CN104582019A, the process involves:

1.Mixing aluminum nitride powder via ball milling, then spray-drying and molding into green bodies.

2.Degreasing and sintering to form sintered bodies.

3.Screen-printing conductive paste (tungsten, molybdenum, or tantalum) to form resistance heating circuits.

4.Bonding ceramic substrates with AlN-based bonding materials and attaching cylindrical supports.

5.Adding countersunk holes to expose resistance heating elements, which connect to external power supply terminals.

This method enables vortex or concentric circuit patterns and ensures reliable heating performance.

China’s Push for Localization

Previously reliant on imports, Chinese companies are now rapidly developing their own ceramic heater solutions. Companies such as Xiamen Innovacera have achieved breakthroughs in AlN-based heaters, which are valued for their near-silicon thermal expansion properties and high-temperature resistance.

The global market for Aluminum Nitride Ceramics heaters is projected to grow at 10% annually, reaching USD 78.5 million by 2031, driven by rising demand for advanced semiconductors. However, challenges such as leakage current control and RF electrode integration still limit widespread adoption.

Future Outlook

“Localizing ceramic heater production is crucial for China’s semiconductor supply chain security,” said an industry insider. With increasing investment in R&D, China aims to reduce reliance on foreign suppliers and strengthen its position in high-end semiconductor equipment manufacturing.

Enquiry

Enquiry