In the electric drive system (motor driver/Inverter) of new energy vehicles, the IGBT power module or power semiconductor module is the core component. They are responsible for converting the direct current (DC) from the battery into alternating current (AC) to drive the motor, while also withstanding high currents, high voltages, and frequent thermal cycles. Silicon nitride (Si3N4) ceramic substrates, with their high thermal stability, high mechanical strength, and excellent electrical insulation properties, have become an indispensable basic material for these power modules.

![]()

It is usually used as the internal support and heat dissipation substrate within the module, directly supporting IGBT or diode chips, and combining with the copper leads or metallization layers in the module packaging to form an “insulated and highly conductive” core structure, thereby ensuring the stable operation of the electric drive system under high power density and harsh environments.

Function and Role:

(1)Heat Dissipation

When the power module is operating, it generates a large amount of heat. The silicon nitride substrate conducts the heat quickly to the heat sink or cooling system through its high thermal conductivity, preventing the chip from overheating and enhancing the stability of the module.

The thermal conductivity of silicon nitride (80-90 W/(m·K)) is not the highest, but its unique combination of high thermal conductivity and high mechanical strength makes it an ideal solution for dealing with the intense temperature variations and strong vibration environments of electric drive systems.

(2) Electric Insulation

The IGBT chips inside the power module need to be electrically insulated from the external metal structure, while at the same time ensuring that heat can be conducted. The silicon nitride substrate has high electrical insulation properties and moderate thermal conductivity, meeting the “thermal-conductive insulation” requirement of this design.

This is the fundamental value of ceramic substrates (including silicon nitride, aluminum oxide, and aluminum nitride).

They form the electrical insulation framework of the power module, ensuring that the working voltage of up to several hundred or even thousands of volts is firmly contained within the module, isolated from the grounded casing and the cooling system, thus guaranteeing the basic safety of the system.

(3) Structural Support

The internal chips, pads, and metal layers of the power module all need to be stably supported. The silicon nitride substrate provides high mechanical strength and resistance to thermal stress, preventing the module from warping or cracking under high-temperature thermal cycling.

This is the key factor that distinguishes silicon nitride from other ceramic materials. Its flexural strength and fracture toughness are more than twice that of aluminum nitride. During the intense temperature fluctuations caused by frequent acceleration and deceleration of the vehicle, different materials (chips, solder, substrate, copper layer) within the module will repeatedly undergo thermal expansion and contraction. The excellent structural strength of silicon nitride can withstand such stress, prevent its own fracture or failure of the connection interface, and ensure the long-term stability of the physical structure.

(4) Enhanced Reliability

The electric vehicle undergoes frequent starting and braking operations, and the power module needs to withstand a large number of thermal cycles. Silicon nitride substrates have excellent thermal shock stability, which can significantly enhance the module lifespan and the overall vehicle reliability.

“Thermal shock stability” is the ultimate manifestation of the combined effects of the above three advantages. Because of its good heat conductivity, the temperature changes rapidly, and there is a small internal temperature difference; because of its high strength, it can resist the huge stress generated thereby. Industry data shows that power modules using silicon nitride substrates can achieve a temperature cycling life that is approximately one order of magnitude longer than that of traditional alumina or aluminum nitride substrates, thereby achieving greater durability and reliability. This directly determines the warranty period and durability of the electric drive system, as well as the entire vehicle.

Application Forms:

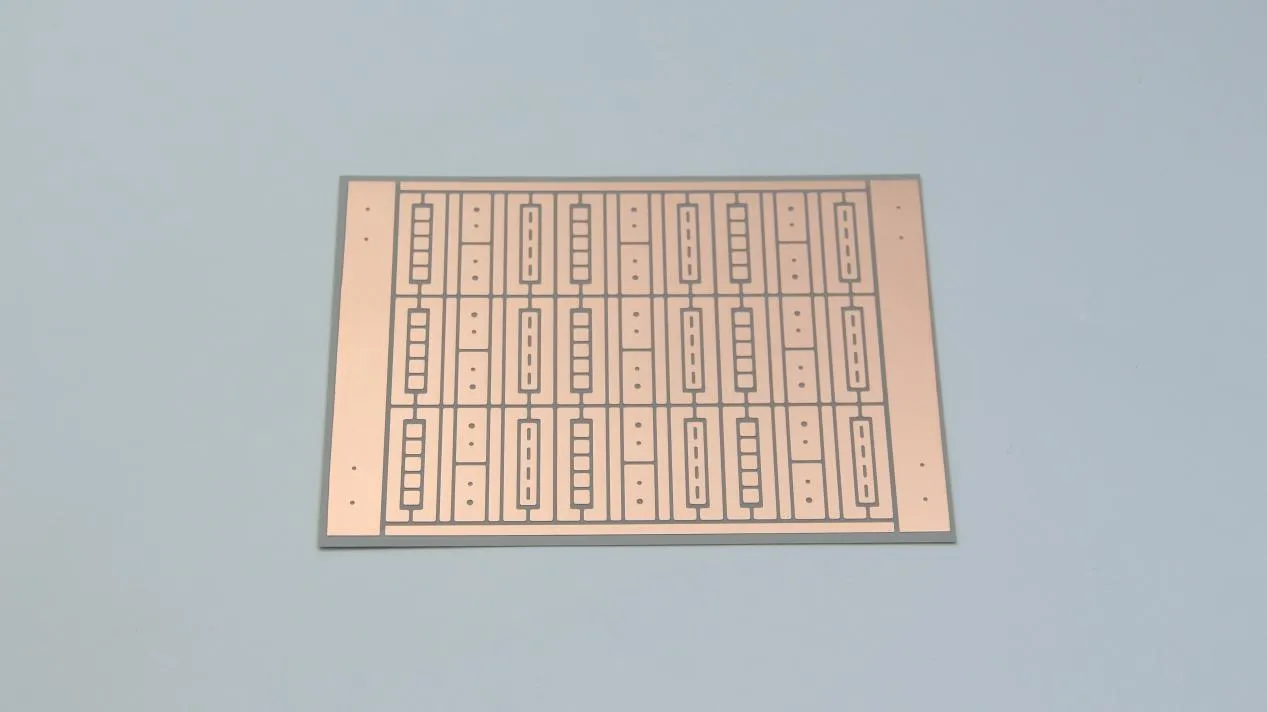

·Metallized Si₃N₄ Substrate

The surface of the silicon nitride substrate needs to undergo metallization treatment (such as the traditional Mo/Mn method, or the current mainstream active metal brazing/AMB technology) to form metal circuits that can be used for welding and electrical connection. This structure enables it to directly support SiC or IGBT power chips and form the core of electrical interconnection within the power module. Among them, the AMB technology, with its higher copper layer bonding strength and excellent thermal conductivity, has become the preferred solution to meet the stringent requirements of automotive-grade power modules for high power density, long lifespan, and high reliability.

Si₃N₄ Substrate after Active Metal Brazing (AMB)

·Direct Integration in EV Power Modules

In the electric drive system of new energy vehicles, the silicon nitride substrate, which serves as the core carrier for insulation, heat dissipation, and structural support in a “three-in-one” manner, is directly encapsulated within the power module of the main inverter. It fixes the power chip upwards and downwards, and it is closely coupled with the module’s liquid cooling heat dissipation system through thermal conductive materials, achieving efficient heat conduction of the chip. This design ensures that the electric drive system can maintain stable output power and reliable long-term performance even during the intense thermal cycles caused by frequent acceleration and braking.

Innovacera offers a full portfolio of Silicon Nitride (Si₃N₄) Substrates, from standard products to fully customized solutions. For inquiries, please contact sales@innovacera.com.

Enquiry

Enquiry