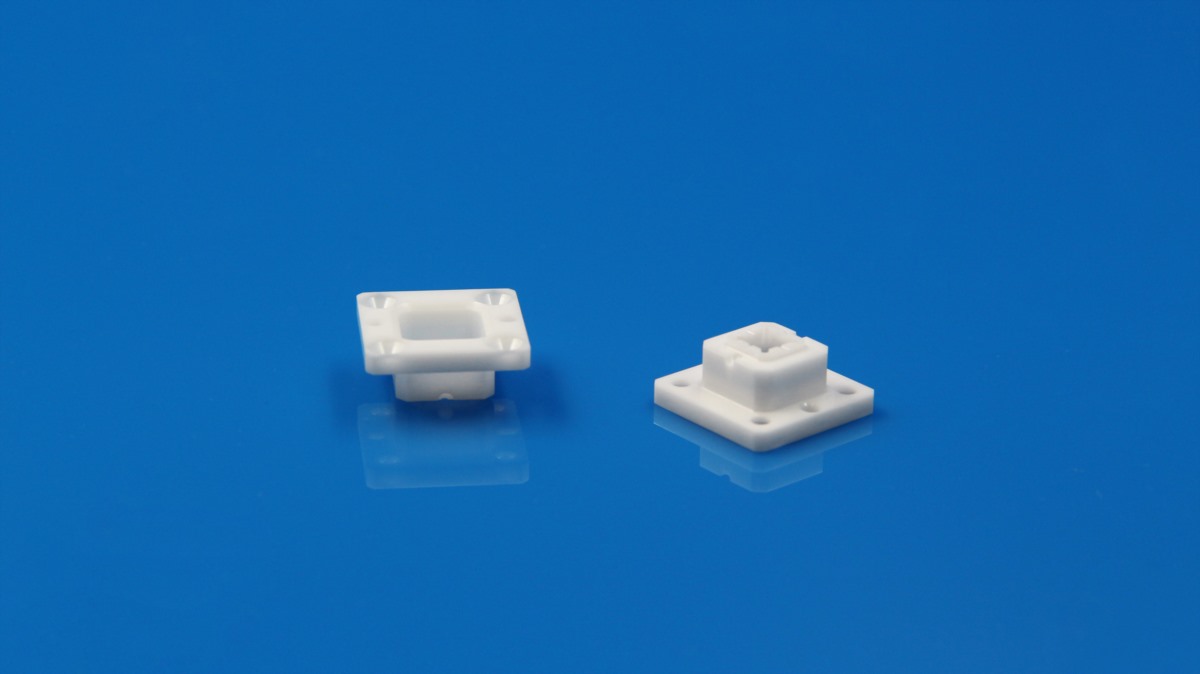

Zirconia (ZrO₂) ceramics are widely used as thermal insulation plates thanks to their excellent thermal insulation performance, high mechanical strength, and outstanding stability at elevated temperatures. The excellent insulation performance of zirconia ceramics comes from their intrinsically low thermal conductivity, which effectively reduces heat transfer. As a result, zirconia insulation plates are commonly employed in various industrial systems that require reliable thermal barriers.

Below are the key features and advantages:

High-Speed Capability

Zirconia ceramics offer strong cold resistance, low elastic modulus, high compressive strength, low thermal conductivity, light weight, and a low coefficient of friction. These properties allow them to be used in high-speed spindles operating from 12,000 to 75,000 rpm as well as other high-precision equipment.

High Temperature Resistance

Zirconia insulation plates maintain stable performance with minimal thermal expansion across 500–600 °C, making them suitable for applications exposed to significant temperature fluctuations.

Corrosion Resistance

Due to their inherent chemical stability, zirconia ceramics resist corrosion from strong acids, strong alkalis, inorganic salts, organic salts, and seawater. This makes them ideal for electroplating equipment, electronic devices, chemical machinery, shipbuilding, and medical equipment.

Antimagnetic Properties

Zirconia insulation plates are non-magnetic and do not attract dust, reducing premature wear, shaft spalling, and operational noise. They are suitable for demagnetization equipment, precision instruments, and other applications requiring non-magnetic components.

Electrical Insulation

With high electrical resistivity, zirconia ceramics help prevent arc damage to shafts and can be used effectively in electrical equipment requiring stable insulation performance.

Vacuum Compatibility

The self-lubricating, oil-free nature of zirconia ceramics overcomes the lubrication challenges faced by ordinary ceramic plates in vacuum environments, making them suitable for vacuum systems and related equipment.

In addition, zirconia ceramic insulation plates offer excellent impact and wear resistance, contributing to their long service life and overall durability. INNOVACERA manufactures a wide range of zirconia components, allowing users to select products based on specific performance and application requirements. For customized insulation solutions, feel free to contact us.

Enquiry

Enquiry