Mass spectrometers are used in industrial, environmental, and clinical applications to detect trace chemicals. This technique heats the ionized sample before it enters the mass spectrometer. Traditional heating methods include using box or cable heaters to heat metal components, which in turn conduct the heat to a flow of high-purity inert gas.

Design requirements

For a mass spectrometer to achieve high detection sensitivity, can achieve most of the analyte level drilling, therefore, must use a contamination-free heat source. In addition, the competitive demand for instrument design to reduce size and complexity while still enhancing sensitivity is also being challenged.

Solution

Ceramic heaters are preferred for ion sources, because the chemical compatibility, low porosity and fine surface finish to reduce the likelihood of contamination. In addition, it has a 400°C (752°F) function, which can meet the performance requirements of most mass spectrometers. In addition, due to the possibility of direct contact with the sample, a high power-to-size ratio offers an opportunity to reduce the complexity and size of the ion source.

Advantages of MCH Heaters :

-Fast Heat-Up Time: MCH heaters heat up quickly due to their low thermal mass, reducing the wait time before you can start soldering.

-Temperature Stability: These heaters offer excellent temperature control and stability, maintaining consistent heat levels even during prolonged use.

-Energy Efficiency: MCH heaters are highly efficient in converting electrical energy into heat, minimizing energy wastage and reducing operational costs.

-Uniform Heating: The uniform heat distribution across the ceramic surface ensures that the soldering tip reaches and maintains the desired temperature evenly.

-Compact Design: MCH heaters are compact and lightweight, contributing to the overall ergonomic design of modern soldering irons.

Properties of MCH Heaters

| Item | Unit | Alumina Ceramic Heater |

| Max. Working temperature | °C | 1050 |

| Working temperature | °C | 850 |

| Thermal conductivity | W/m.k | 21 |

| Specific Heat | J/kg.k | 0.78X103 |

| Expansion | /°C(40-800°C) | 0.78X10-6 |

| Hardness (load 500g) | Gpa | 13.5 |

| Flexural | Mpa | 320 |

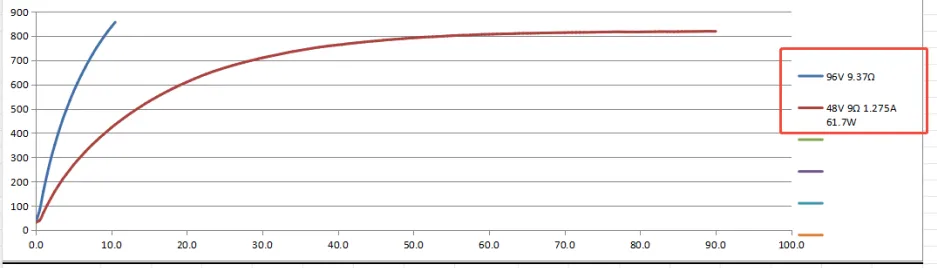

Temperature curve of MCH heater

Below are some regular heaters used for mass spectrometer

More application for MCH heater

E-cigarettes, 3D printers, auto/motor oxygen sensors heater, smart bide/Instant water heating, small home appliances such as kettles, hair straighteners, curlers, hair dryers etc.

Due to their outstanding performance, ceramic heaters are extensively used in mass spectrometers and are highly regarded by customers worldwide. For more information, please contact us.

Enquiry

Enquiry