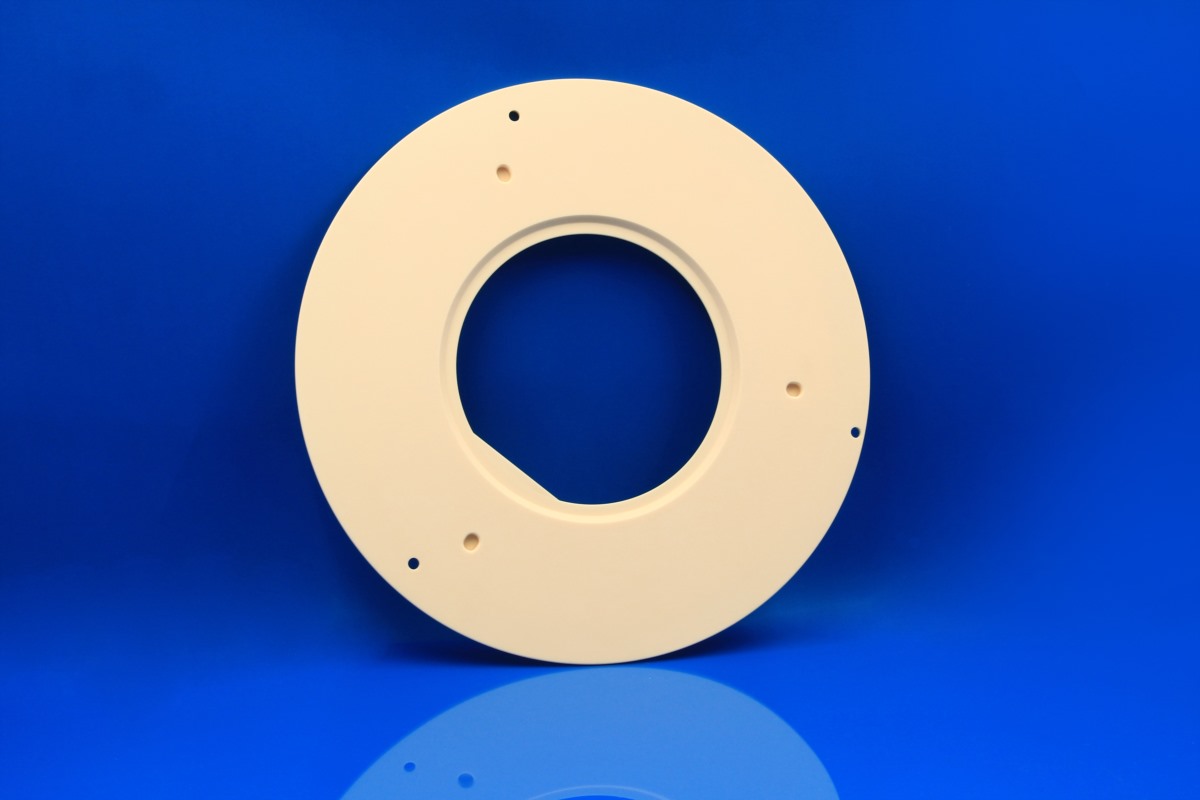

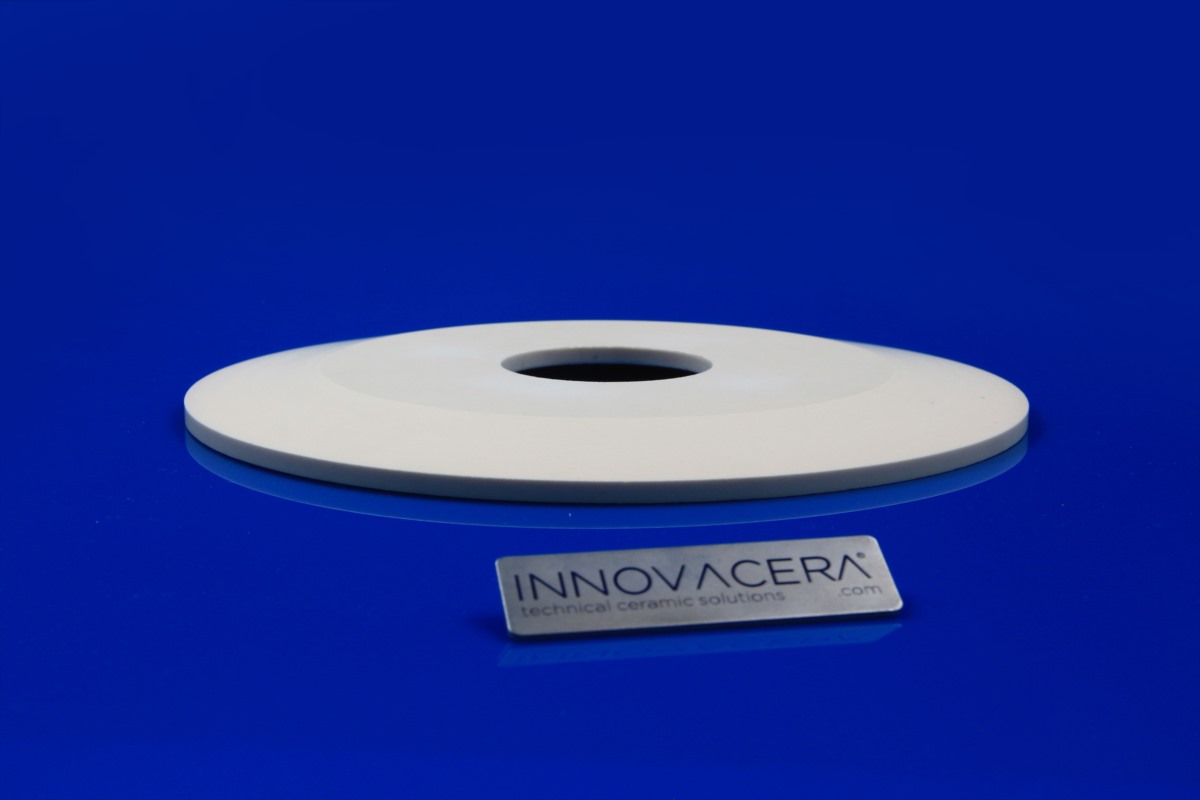

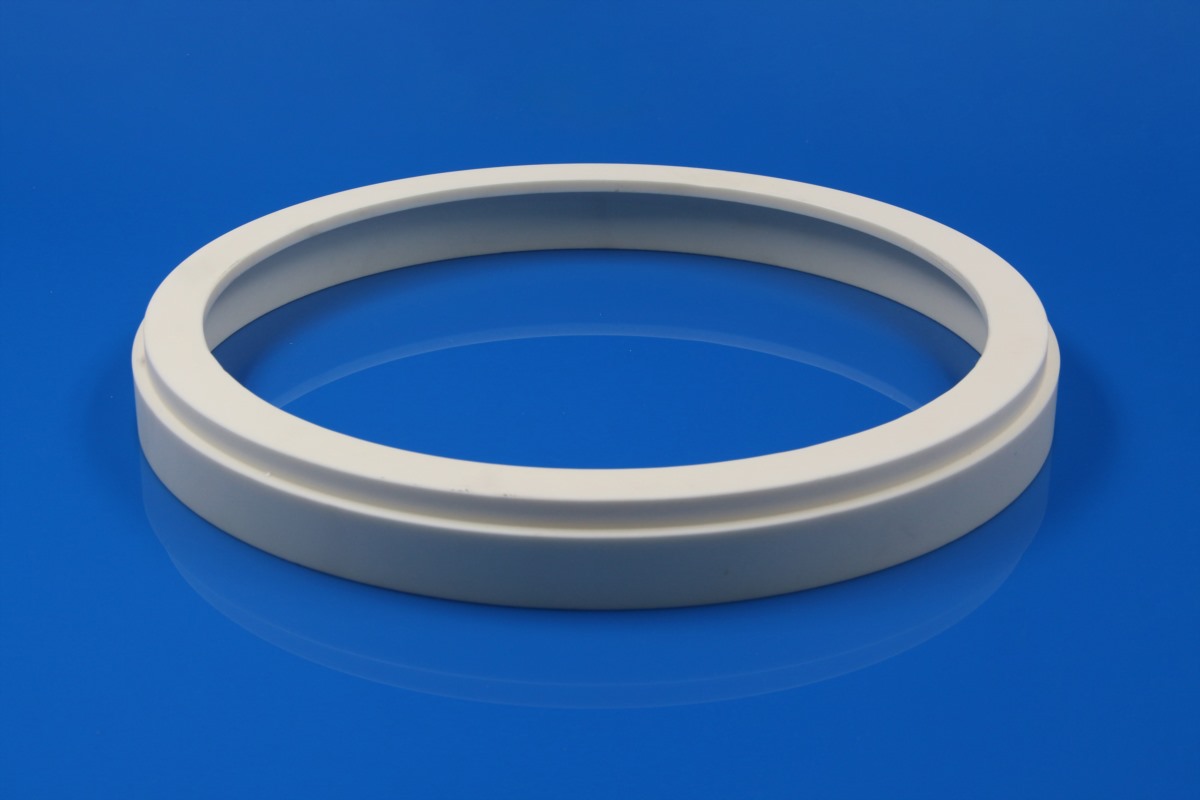

Alumina Ceramic Focus Rings serve as critical components within plasma etch equipment, primarily in the etch chamber. The rings are strategically positioned to optimize plasma distribution and maintain uniformity during the etching process.

Semiconductor manufacturing processes demand operation within cleanroom environments, especially for components utilized under high-temperature, vacuum, and corrosive gas conditions. Ceramic materials maintain high stability within these complex physical and chemical environments.

The Ceramic Focus Ring is a critical part for the Semiconductor Etch Process. When aluminum alloy is chosen as the etch chamber material, it can easily cause metal particle contamination. Therefore, high-purity (over 99.5%) alumina ceramic is used in the manufacturing of Ceramic Focus Rings as the chamber material for plasma etching equipment.

Ceramic Focus Rings characteristics:

-Wear Resistance,

-Corrosion Resistance,

-Excellent Mechanical Properties,

-Electrical Insulation,

-Meet the quality standard of semiconductor product.

Innovacera have rich experiences in technical ceramic solution, advanced ceramic component and semiconductor industry more than 10 years. We have established a high standard of quality system and strict quality control process, each batch of products are subjected to strict quality inspection. The service philosophy of Innovacera is meeting quality requirement and customer satisfaction.

If you need the alumina Ceramic Focus rings, welcome to contact us.

Enquiry

Enquiry