Semiconductor chips are ubiquitous in modern technology. They are essential in the evolution of various electronic devices and systems, including smartphones, smartwatches, computers, automobiles, big data, cloud computing, and the Internet of Things (IoT). Semiconductor equipment comprises thousands of components, whose performance, quality, and precision directly influence the reliability and stability of the equipment. Consequently, a significant amount of precision ceramic parts is required in semiconductor equipment.

Advantages of Precision Ceramics

Ceramics are utilized extensively due to their high hardness, high elastic modulus, high wear resistance, excellent insulation, good corrosion resistance, and low expansion. These properties make ceramics suitable for components in various semiconductor devices such as silicon wafer polishing machines, thermal processing equipment (epitaxy/oxidation/diffusion), lithography machines, deposition equipment, semiconductor etching equipment, and ion implantation machines. The main types of semiconductor ceramics include alumina, silicon nitride, aluminum nitride, boron nitride, and silicon carbide and so on. In semiconductor equipment, precision ceramics account for approximately 16% of the total value.

Applications of Ceramics in Semiconductor Equipment

Here is an overview of the different ceramic components used in various semiconductor processes:

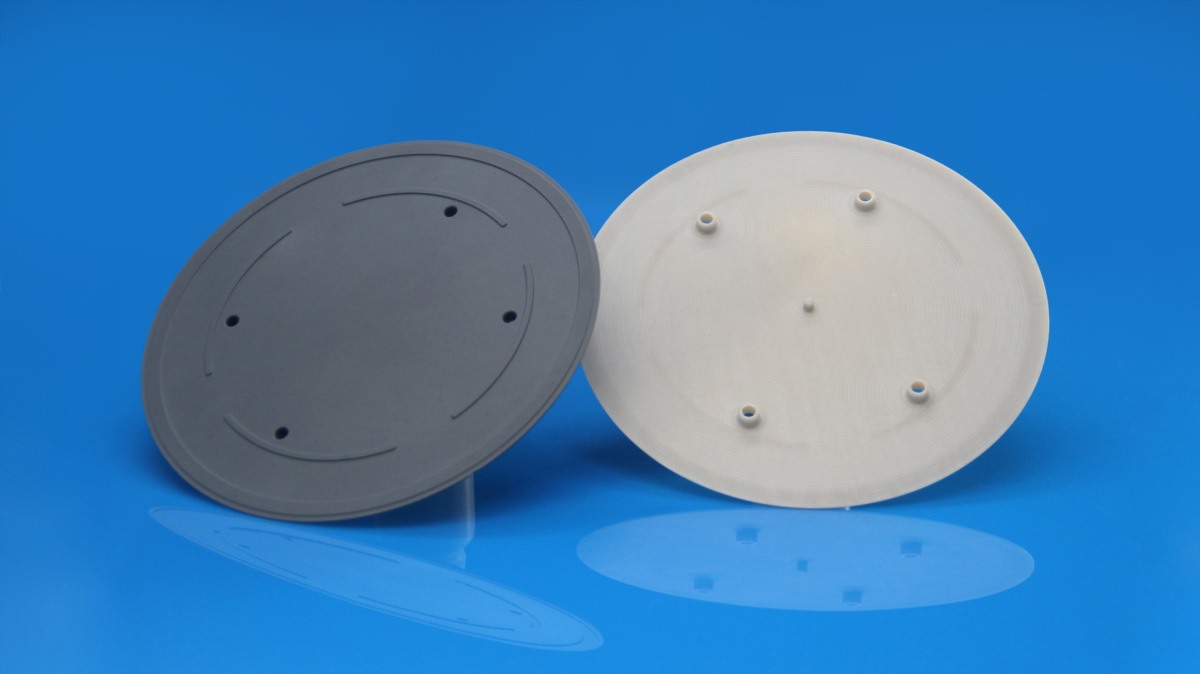

1.Chemical Mechanical Planarization (CMP)

– Ceramic polishing tables

– Ceramic polishing plates

– Ceramic lapping plates

– End Effector

– O-ring ceramic sealing

2.Lithography machine

– Vacuum chuck

– Wafer chucks

– Ceramic worktables

– End Effector

– Ceramic working wheels

– Ceramic valves

– Ceramic filters

3.High-Temperature Processing (RTP/Epitaxy/Oxidation/Diffusion)

– Ceramic Insulators

– Ceramic substrates

– Wafer boats

– Furnace tubes

– Cantilever paddles

4.Deposition equipment

– O-ring ceramic sealing

– Ceramic valves

– Chamber covers

– Chamber liners

– Deposition rings

– Electrostatic chucks

– Ceramic Heating elements

– Electroplating insulators

– Vacuum break filters

5.Etching

– Domes

– Chambers

– Focus rings

– Ceramic Nozzles

– Electrostatic chucks

– End effector

6.Ion Implantation

– Ceramic Bearings

– Vacuum chuck

– Electrostatic chucks

– Ceramic Nozzles

Commitment to Quality and Innovation

Innovacera integrates advanced technologies and continuously pursues research and development. We approach each customer’s requirements with a scientific and rigorous attitude, striving for excellence to produce products that best meet our clients’ needs. We welcome detailed inquiries and look forward to providing more ceramic solutions and professional service for you!

Feel free to contact us with your specifications and requirements.

Enquiry

Enquiry