Ceramic materials, with their high melting points and excellent insulating properties, present significant challenges when it comes to joining them with metals. Traditional welding methods often struggle to create strong and reliable bonds. However, advancements in joining technologies have introduced Vacuum Brazing as a highly effective solution. This process not only overcomes the limitations of ceramics but also leverages the benefits of both materials to create composite components.

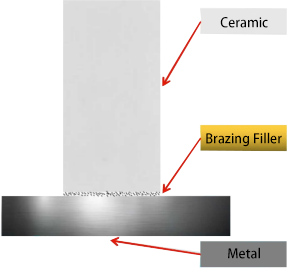

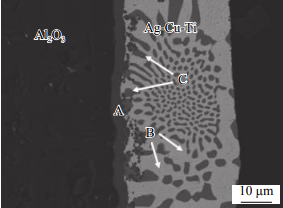

Vacuum brazing is particularly advantageous due to its ability to join ceramics and metals at high temperatures in a vacuum environment, which minimizes oxidation and other unwanted reactions. Ceramic-to-metal sealing process often involves the use of a brazing filler metal, which can be tailored to the specific materials being joined. One such technique is Active Metal Brazing, where a reactive element in the filler metal, such as titanium in Ag-Cu-Ti, activates the ceramic surface, facilitating a strong bond.

When considering the joining of ceramics to metals, the high melting points and poor thermal stability of ceramics present a formidable challenge. Traditional welding methods often fall short, but Vacuum Brazing has emerged as a superior alternative. This process capitalizes on the unique properties of both materials, creating strong and reliable Ceramic to Metal bonds.

While there are various methods for joining ceramics and metals, including mechanical joining and solid-state diffusion bonding, Vacuum Brazing offers a combination of performance, cost-effectiveness, and ease of implementation that is unmatched.

The process of Vacuum Brazing involves the use of a brazing filler metal that melts at a lower temperature than the materials being joined. In the case of Ceramic to Metal bonding, Active Metal Brazing with Ag-Cu-Ti powder as the filler metal is particularly effective. The active element, titanium, reacts with the ceramic surface, cleaning and activating it for a stronger bond.

For instance, when brazing Al2O3 ceramics with 304 stainless steel, metallized ceramic surfaces are prepared, and AgCu is used as the brazing filler metal. The Vacuum Brazing process ensures that the resulting joints can withstand high-temperature tests, demonstrating exceptional hermeticity and reliability.

The use of Active Metal Brazing in Vacuum Brazing allows for the achievement of shear strengths of up to 130 MPa in brazed joints. This highlights the significant potential of Vacuum Brazing in creating durable Ceramic to Metal connections that are suitable for a wide range of applications.

As research in this field progresses, Vacuum Brazing continues to evolve, offering ever-improving joint strength and versatility. It stands as a critical technology in material joining, pushing the boundaries of what is possible in the creation of Ceramic to Metal composite components.

Enquiry

Enquiry