In Zirconia ceramic family, there is a material can endure the high temperature 2200 degree centigrade. We call it Magnesium Stabilized Zirconia ceramic. It is a refractory material. Although 95% of the composition is zirconium oxide, its performance is quite difference with the white zirconia ceramic .

From its appearance, it is yellow color and with porosity. We have two kind magnesium stabilized zirconia ceramic. One with low porosity its density is ≤52g/cm3, one with high porosity its density a little higher 5.4-5.6g/m3. But their main composition is almost the same. They can be used in air, vacuum or protective atmosphere environment. Following is the detail of the material data sheet.

| Property | Item | Units | MSZ-H | MSZ-L |

| Composition | ZrO2 | % | ≥95 | ≥95 |

| Al2O3 | % | ≤0.2 | ≤0.2 | |

| SiO2 | % | ≤0.4 | ≤0.4 | |

| MgO | % | ≤2.9 | ≤2.9 | |

| Fe2O3 | % | ≤0.1 | ≤0.1 | |

| TiO2 | % | ≤0.1 | ≤0.1 | |

| Physical | Color | Yellow | Yellow | |

| Density | g/cm3 | ≤5.2 | ≤5.4-5.6 | |

| Porosity | % | ≤18.5 | ≤8 |

The feature of Magnesium stabilized zirconia

*High erosion and wear resistance

*High thermal shock resistance

*Metal corrosion resistance in high temperature

*Long service life

*High Strength

Application Field

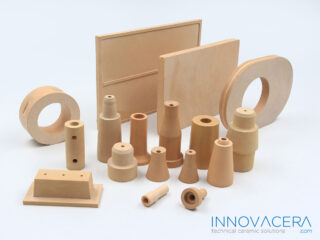

*Metal powder industry as gas atomizing nozzle and setter plate

*Precious metal smelting industry as ceramic crucible

*High-temperature melt flow control components such as sizing nozzles, ladle skateboard panels, converter slag blocking slide plates, and rings

If you are looking a ceramic material for ultra high temperature, magnesium stabilized zirconia ceramic may be a good choice. Its stabilizers and grains combination can be designed according to customer’s using environment as long as you have the quantity. Any more question about it, just feel free to contact us at +86 592 558 9730 or sales@innovacera.com for more information.

Enquiry

Enquiry