Innovacera can provide a range of crucibles for electron guns, which can also be designed and customized to meet specific needs. May I know if you have chosen the most suitable crucible for aluminum plating? This article explains in detail how to choose it, let’s go down.

Aluminum will form alloys with tungsten crucibles, molybdenum crucibles, and tantalum crucibles, which cause corrosion on the inside of the crucible and also contaminate aluminum. At the same time, the film layer has been contaminated, such as the film being black, dark, and even spotted. Aluminum will also form yellow aluminum carbide with carbon in graphite crucibles, and the formed aluminum carbide will evaporate onto the sample, causing the film to turn yellow. The use of boron nitride crucibles, alumina crucibles, or quartz crucibles is prone to electron beam defocusing issues. The main reason is that the crucible is not conductive, and the excess electrons in the crucible accumulate, resulting in repulsion of the electron beam. The use of conductive boron nitride crucible aluminum plating can effectively solve the problems encountered with ordinary crucibles. The aluminum film is of high quality and the crucible has a long service life.

Common Causes of Crucible Breakage:

The first reason is that the ramp/soak levels are wrong for that material. The second reason the user shuts the power supply off or has a very short ramp down time for power after the deposition is done. This causes the rapid solidification of the melt, and this stresses out the crucible liner.

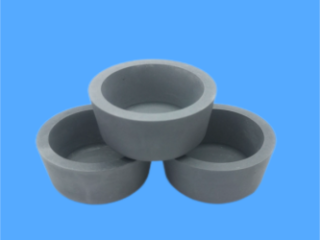

Advantages of BN-TiB2 Crucibles:

1. Custom sizes available upon request.

2. The crucible is conductive and the electron beam can work normally.

3. It will not pollute the aluminum, and the plated aluminum film has high purity.

4. Recommended for aluminum evaporation.

5. The special design can effectively reduce the power of the electron gun.

6. The special design makes the crucible not easy to crack.

7. Intermetallic crucibles are both conductive and lubricious and are ideal for materials that have a tendency to creep up the sides of the crucible.

INNOVACERA produces a series of crucibles, and you can pick up according to the specific requirements and areas of application. If you need any E-Beam Crucibles, please feel free to contact us.

Enquiry

Enquiry