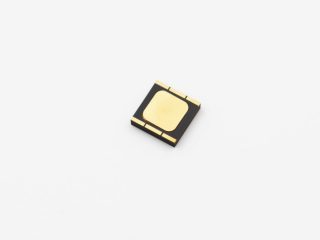

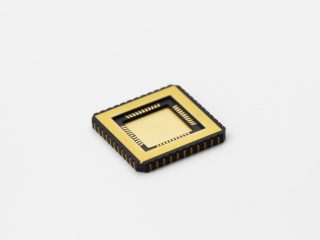

Beryllia ceramic components provide more product strength, more reliability, more miniaturization, more weight savings, and more thermal management in the world.

Beryllia ceramics have a very high thermal conductivity which is second only to diamond in the insulator material. Its superior performance at high temperatures has created a market demand for beryllium oxide ceramic (BeO). No other material can economically deliver the same performance and reliability demanded by today’s high-tech products and systems.

Beryllia ceramic features:

- Low Dielectric Constant

- High Electrical Resistivity

- Superior Thermal Conductivity

- Easy and Effective Metallization

- More Consistent Heat Dissipation

- Low coefficients of thermal expansion

- Better Uniformity of Crystalline Structure

- More Durable in Semiconductor Chamber Cleaning Environments

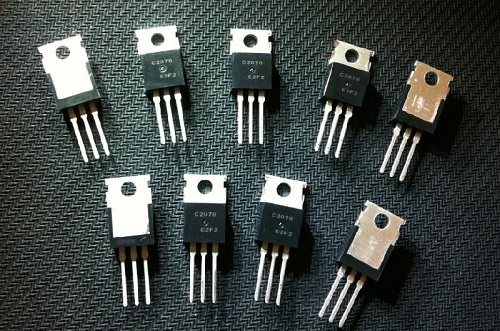

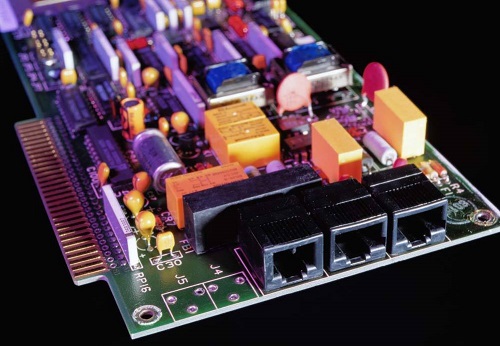

Beryllia ceramic application:

- MRI machines

- High power electronics

- Semiconductor processing

- Microwave communications

- Transmitters for radio frequency

- Oil and gas exploration equipment

- Long-range fiber optic transmission

- Laser energy used in medical eye surgery

- Missile guidance systems in military industry

- Industrial laser metal-cutting and marking equipment

- Airplane and satellite communications systems in aerospace field

- Support components and assemblies in avionics conversion circuitsBeryllia Ceramic Component Features

Beryllia Ceramic Components Applications

Enquiry

Enquiry