The working temperature of the boron nitride ceramic crucible is 1900°C under vacuum and 2100°C under atmosphere protection. Nitrogen or argon atmospheres are best, it makes have the longest life.

The boron nitride crucible has strong thermal shock resistance, 1500°C fast cooling without cracking, and 1000°C furnace holding for 20 minutes, taking it out and blowing and fast cooling for hundreds of times continuously without cracking.

Note:

1. The use temperature in the air should not be more than 900 °C, and the surface of boron nitride and oxygen will be oxidized and peeled if it exceeds 900 °C.

2. Boron nitride is easy to absorb moisture. The crucible can’t be stored in wet areas and can’t be washed with water. It can be directly wiped with sandpaper or scrubbed with alcohol.

3. Application direction of boron nitride crucible

【Available materials】:

- Ferrous metals: iron, copper, aluminum, nickel, magnesium, bismuth, zinc, etc., alloy FE-CO-NI-SI CO-ZR-NB

- No reaction between water and acid at room temperature. Slowly hydrolyze with water to produce boric acid and ammonia

- Rare Earth, Nitride

【Material not available】:

- Antimony trioxide, chromium heptaoxide, molybdenum trioxide, arsenic trioxide, titanium carbide, etc.

- High lead glass glaze will corrode BN when melted in the air at 800-950 °C, but it will not react under the protection of nitrogen or inert gas.

- Boron phosphate corrodes boron nitride in nitrogen at 1400 °C and reacts with hot concentrated or molten alkali and hot chlorine gas.

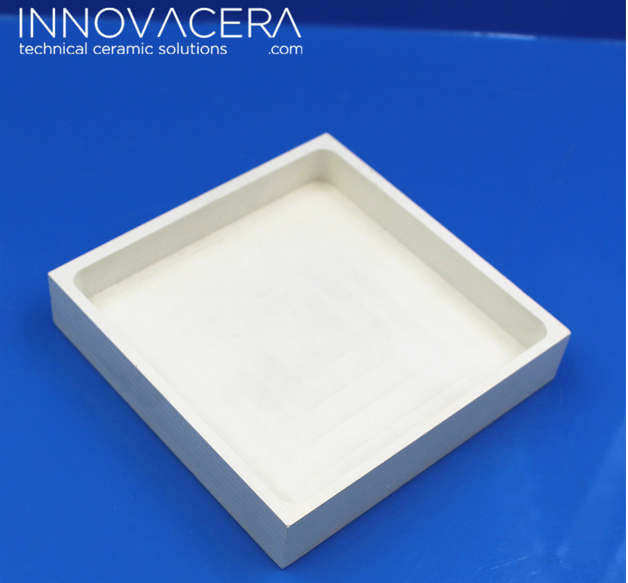

Boron Nitride Ceramic Crucibles

Boron Nitride Ceramic Crucible

Enquiry

Enquiry