One of the main materials supplied by INNOVACERA-Boron Nitride is mainly used in refractory materials, semiconductor solid-phase doping sources, structural materials of atomic piles, packaging materials to prevent neutron radiation, rocket engine components, high-temperature lubricants and release agents.

Boron nitride baking plate is a tool used in ceramic kilns to carry and transport fired ceramic bodies.

These sheets have many excellent properties that make them widely used in ceramics and other high-temperature industrial applications.

Boron nitride Setter features and applications:

High purity: Boron nitride setters usually have high purity, which can reach more than 99.7%.

This prevents it from sticking to the product, contaminating the fired ceramic, and has a long service life.

High temperature resistance: The maximum operating temperature of boron nitride setter plate can reach 2100 degrees Celsius.(Under atmospheric protection)

And it has good resistance to high and low temperature repeated impact and carbon corrosion resistance.

Boron nitride setters are widely used in the following scenarios:

1. Push plates, burners, shed plates, and saggers for ultra-high temperature electric kilns and electric furnaces

2. Pollution-free high-temperature sintering of magnetic materials, powder metallurgy, ceramic substrates, zirconia ceramics ,ALN, Si3N4 and other industrial ceramics.

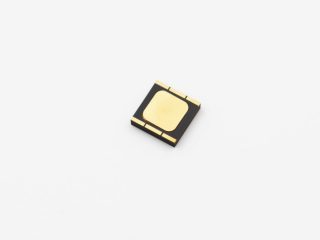

3. Sintering of electronic components (such as MLCC, LTCC, PTC chip resistors and capacitors).

In short, boron nitride burner plates carry and transport fired ceramics in high-temperature environments, improve firing efficiency, and reduce energy consumption. They are one of the indispensable key materials in the ceramic industry.

Enquiry

Enquiry