How to prevent moisture or gas penetration while enabling electrical or optical signal transmission; and how to protect sensitive optoelectronic components from environmental influences. These are common challenges faced during the design process.

This is when the “hermetic packaging” technology, which has been in mature use for decades, comes into play. It can achieve signal and power transmission while maintaining air-tightness. Hermetic packaging is also used for optical signal transmission. For example, vacuum – sealed optical lenses or flat – window tube caps are often used in the packaging of sensors.

The two transmission functions of hermetic packaging are electrical signal transmission and optical signal transmission.

– Electrical Power/Signal Transmission: Hermetically sealed connectors can conduct through the sealed housing while preventing the intrusion or escape of moisture, gas and other substance.

– Optical Signal Transmission: Hermetically sealed lens or caps allow the emission or transmission of optical signals.

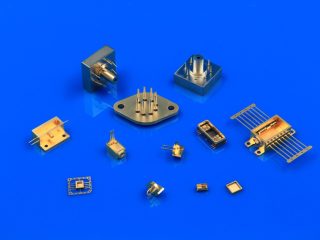

Hermetic packaging comes in various forms, including electrical package, cable feedthroughs, connectors, joints or conductor terminals, etc.

What are the application cases of hermetic packaging and what functions do they serve?

1.Meeting the Challenges of Extreme Environments

Hermetic packaging can protect electronic devices to operate stably in specific environments, such as high temperature, high pressure, humid and corrosive environments.

Product Performance Indicators:

– Prevent moisture and gases. (Helium leakage < 10⁻⁸ mbar·l/s)

– Resist high and low temperatures.Temperature range: -200°C ~ 1000°C, for example, it can be applied in the cryogenic LNG industry and automotive exhaust gas sensors.

– Withstand high pressure. Withstand up to 400 MPa of high pressure and can be used in oil and natural gas exploration.

2.Enhancing System Reliability and Safety

In addition to challenging working environments, hermetic sealing can extend the service life and improve the efficiency of products. For example, applications that are not convenient for replacement and maintenance, or where the maintenance cost of the electrical system is too high – aviation, aerospace and maritime applications.

3. Improving Performance, Efficiency, and Design Innovation

Hermetic packaging can also significantly enhance performance, efficiency, and design innovation. In optical communication and data communication applications, a truly airtight or waterproof enclosure is required to achieve long – term, stable, and high – performance data transmission.

Hermetic packaging can also be a cost – effective alternative to non – sealed or quasi – sealed solutions because it can be combined with more miniaturized and simplified single – component designs instead of large and complex multi – component systems. Through special designs, hermetic packaging can also meet special data transmission requirements such as heat dissipation, high – power/voltage/insulation, or high – RF optical signals.

4.High Cost – Performance and Widely Used in Automotive and Home Appliance Electronics

The production process of hermetic packaging products is highly mature, capable of providing a large number of products with stable quality and having a competitive price. It has been applied in various industries. For example, the hermetic tube seats of automotive airbags and seat belts have extremely high reliability and meet the 0 PPM quality control requirements. In the home appliance industry, hermetic terminal blocks provide stable power supply for refrigerator and air – conditioner compressors.

The basic purpose of vacuum sealing and hermetic packaging is to assist in the reliable operation of electronic devices and systems – – especially in some extremely harsh application scenarios. It is widely used in many important industries, including automotive electronics, medical equipment, etc., and the product quality is trustworthy. As the only viable solution for electronic protection, hermetic packaging increases product value, meets customer requirements, and is used in various industries and daily consumer electronics.

Enquiry

Enquiry