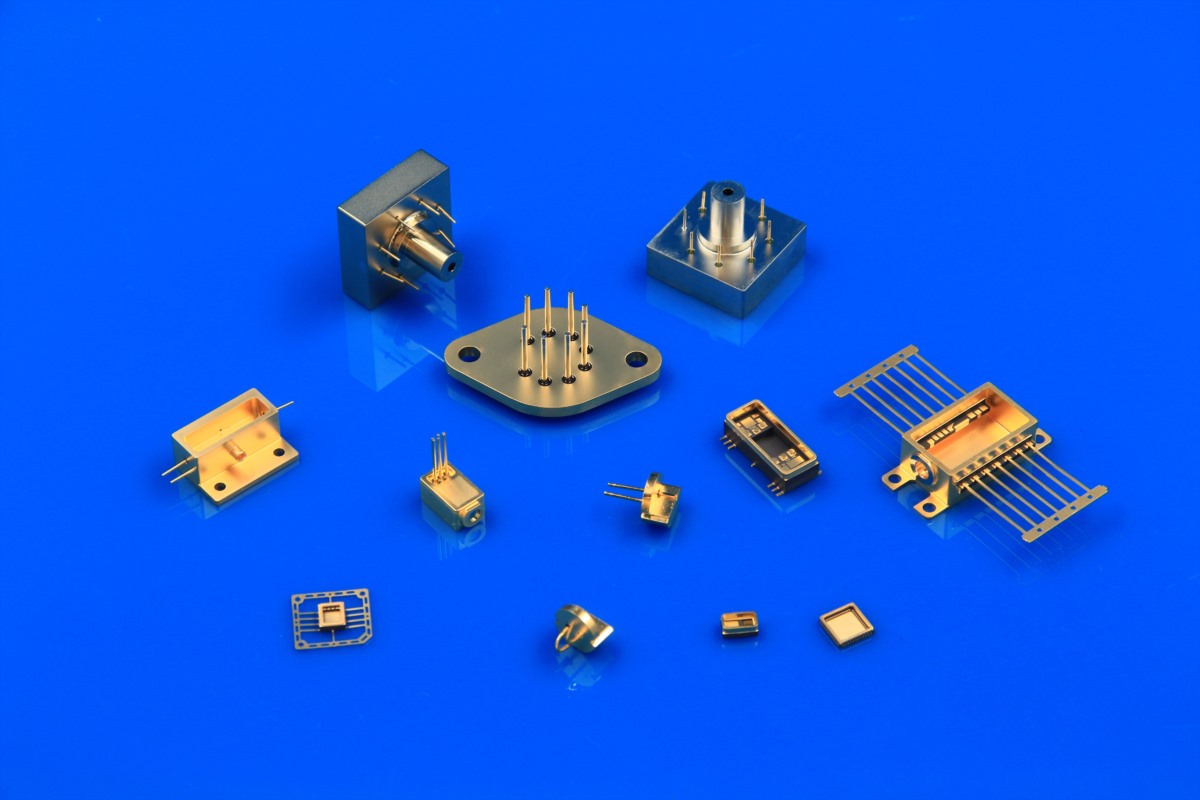

Products

Metal packaging

The integrated circuit package shell provides a sealed, stable, and efficient heat dissipation operating environment for the chip through glass-metal and ceramic-metal packaging, protecting the device from humidity, temperature changes, and other physical and chemical environmental conditions. It is mainly used in base station radars, electronic countermeasures, measurement and control instruments, equipment signal power supplies, etc.

Technical advantages

-It can realize the packaging of Kovar, carbon steel, stainless steel, tungsten copper and aluminum alloy, and can also meet the energy storage

Welding, parallel seam welding, tin soldering and laser sealing welding and other welding methods;

-Insulation resistance ≥5000MΩ (500V DC);

-Air tightness: R1≤1×10-3Pa·cm3/S (He);

-Salt spray resistance: can meet 24h, 48h, 72h corrosion resistance test;

-It has a full industrial chain ecosystem from R&D, design to production and manufacturing, and can provide customized services

Product model

-Signal processing device housing

-Power module package

-Motor drives and PWM package

-Ceramic package for semiconductor discrete device

-Replay package

-Lid and cap

-Power surface mount package

HTCC ceramic package shell

-Ceramic Dual in-line Package (CDIP)

-Ceramic Flat Pack /Ceramic Quad Flat Pack (CFP/CQFP)

-Ceramic Quad Flat Non -leded Package(CQFN)

-Ceramic Pin Grid Array (CPGA)

-Ceramic Small Outline Package (CSOP)

-Ceramic Leadless Chip Carrier (CLCC)

Technical advantages

-Plating is self-controlled;

-Advanced design and simulation technology can optimize the design of ceramic shell/substrate structure, wiring, heat, reliability, etc.;

-It has an ecological system of the entire industry chain from R&D, design to production and manufacturing, and can provide customized services.

LTCC ceramic package shell

LTCC (Low Temperature Co-fired Ceramic) is a multilayer ceramic substrate, the main components of which are alumina and glass, and high conductivity metals such as gold, silver, and copper are used as conductor pastes, which are co-fired at a relatively low temperature (850℃~900℃). LTCC substrates and shell products are particularly suitable for the packaging of RF, microwave, and millimeter wave devices due to their low conductor resistivity and small dielectric constant.

Technical advantages

-Thinnest line and line spacing: 100µm;

-Smallest aperture: 100µm;

-Smallest hole spacing: 2.5 times the aperture;

-Maximum number of layers: 40 layers;

-There are two types of product systems for customers to choose from: high-frequency low-loss and high-strength.

Material System

| Base Materials Performance | ||||

| Materials | Code | Density g/cm² | CTE 10⁻⁶/℃ (20℃~300℃) | TC W/m·K |

| Iron-nickel-cobalt alloy | 4J29 | 8.2 | 5.3 | 17 |

| Nickel-iron-Alloy | 4J42 | 7.12 | 4.8 | 13 |

| Plain Carbon Steel | 10# | 7.8 | 13.0 | 46 |

| OFHC | TU1 | 8.9 | 17.6 | 390 |

| W/Cu | WCu85/15 | 16.4 | 7.2 | 180 |

| Stainless Steel | 304/316 | 7.93/7.98 | 17.2/20 | 16/16.29 |

| Pin Materials Performance | |||

| Pin Material | Code | Resistivity μΩ-cm | CTE 10⁻⁶/℃ (20℃~300℃) |

| Iron-nickel-cobalt-Alloy | 4J29 | 48 | 5.3 |

| Nickel-iron-Alloy | 4J50 | 43 | 9.5 |

| Cu Cored 52 Alloy | 4J50 | 12 | 11.5 |

| Cu Alloy | Tul | 1.7 | 17.6 |

Typical Applications

-High-power laser TO packages

-Automotive relay sealing

-Discrete semiconductor devices

-Multilayer Ceramic Substrates

-Surface-Mount Power Packages

-Optical Communications: 400G transceiver hermetic sealing

-Automotive Electronics: LiDAR emitter packaging for autonomous driving

-Optical Communications: 400G transceiver hermetic sealing

-New Energy: Insulation terminals for battery management systems (BMS)

Enquiry

Enquiry