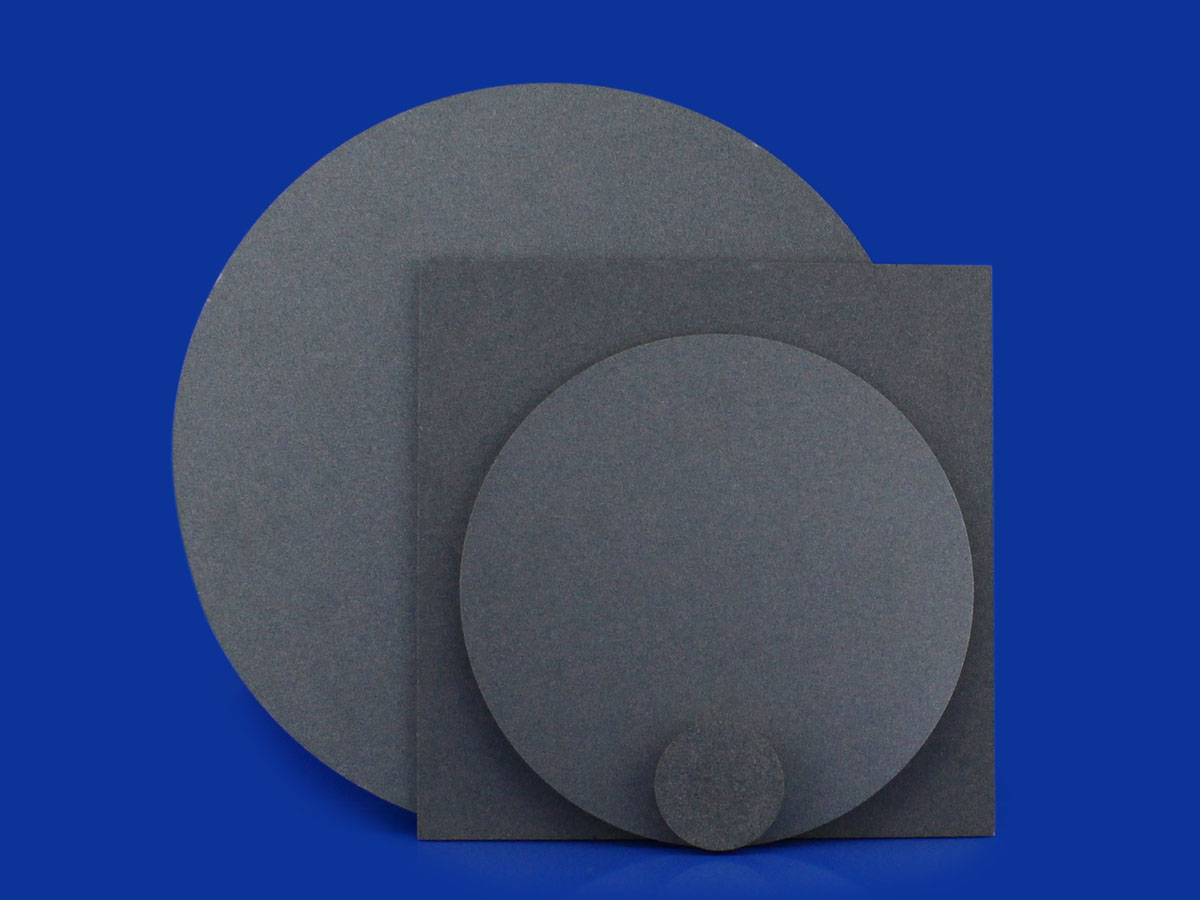

Application:

Semiconductor wafer processing, laser numerical control processing, PCB, flexible screen, precision grinder, air floating platform, air bearing, optical components.

1) The smaller the pore size, the greater the resistance and the greater the degree of vacuum required, but the greater the suction power obtained.

2) The maximum use temperature of alumina/silicon carbide microporous ceramics is about 1000 ° C, and the maximum use temperature is also related to size and shape. Still, if glue is stuck, it can only be lower than 100 ° C.

3) Microporous ceramics generally do not mention the roughness problem, because there are micropores, but the surface smoothness is similar to Ra0.8 of dense ceramics.

4) Low thermal conductivity. Only dense materials will have high thermal conductivity.

5) Microporous ceramics cannot be used in a humid environment or come into contact with conductive liquids. Otherwise, they will not be insulated.

Enquiry

Enquiry