Aluminum nitride is a covalently bonded compound with a hexagonal brazingite structure. Aluminum nitride has a series of excellent features as below:

- Excellent thermal conductivity,

- Reliable electrical insulation,

- Low dielectric constant,

- Dielectric loss,

- Non-toxic,

- Has a thermal expansion coefficient that matches silicon.

Aluminum nitride has become a material of great concern in the electronics field due to its excellent thermal conductivity and thermal expansion coefficient matching that of silicon.

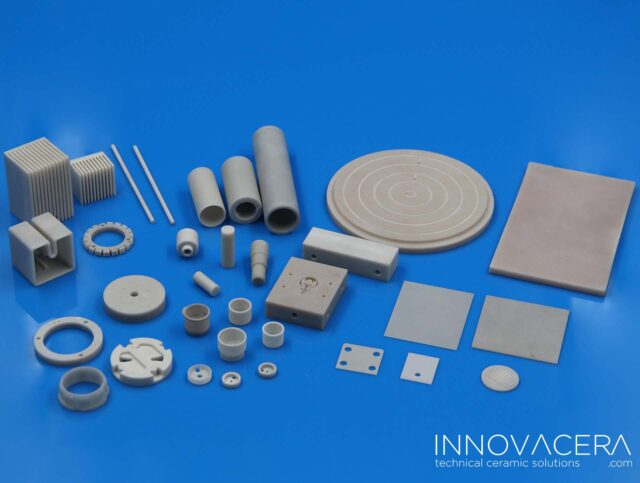

ALN material is not only an ideal material for new generation heat dissipation substrates and electronic device packaging, but also can be used in heat exchangers, piezoelectric ceramics and films, thermal conductive fillers, etc., with broad application prospects.

The crystal structure of AlN determines its excellent thermal conductivity and insulation properties. According to the study “Research on Tape Casting and Sintered Body Properties of Aluminum Nitride Ceramics“, due to the small atomic weight of the two elements that make up the AlN molecule, the crystal structure is relatively simple and has good harmonicity, and the formed Al-N bond The bond length is short, the bond energy is large, and the resonance of the covalent bond is conducive to the phonon heat transfer mechanism, making the AlN material superior to general non-metallic materials in thermal conductivity. In addition, AlN has a high melting point, high hardness and high thermal conductivity , and better dielectric properties.

According to the research “New Progress in Research on Factors Affecting Thermal Conductivity and Bending Strength of AlN Ceramics”, AlN has received widespread attention due to its high matching of thermal expansion coefficient with Si, while traditional substrate materials such as Al2O3 have been widely used due to their thermal conductivity. The rate is low, its value is about 1/5 of AlN ceramics, and the linear expansion coefficient does not match that of Si, which can no longer meet actual needs. The thermal conductivities of SiC ceramic substrates are also relatively high, but SiC has poor insulation. As a new type of highly thermally conductive ceramic material, AlN is expected to become an excellent material to replace Al2O3, SiC as ceramic substrates in the electronics industry.

| Properties | Units | ALN | AL2O3 | SIC |

| Density | g/cm3 | 3.26 | 3.6 | 3.12 |

| Bending Strength | MPa | 300-500 | 300-400 | 350-450 |

| Specific Heat | J / (g·K) | 0.75 | 0.75 | – |

| Thermal Conductivity(20 ℃) | W / (m·K) | 170-220 | 20-35 | 50-270 |

| Resistivity (20 ℃) | Ω·cm | 8.8 | 9.3 | 40 |

| Mohs Hardness | Gpa | 9 | 9 | 9.2-9.5 |

The Semiconductor and new energy markets stimulate AlN demand growth very much.

Aluminum nitride ceramics have been widely used in many civilian due to their excellent properties in many aspects. The advent of the 5G era, the era of new energy vehicles and the era of artificial intelligence has created more demand for aluminum nitride ceramics in many applications. Such as heat dissipation substrate and electronic device packaging.

The global ceramic substrate market is booming, and the market size is growing steadily. AlN ceramic materials can be used as copper-clad substrate materials, electronic packaging materials, ultra-high temperature device packaging materials, high-power device platform materials, high-frequency device materials, sensor film materials, optical electronic device materials, coatings and functional enhancement materials, etc. According to the Maxmize Market Research report, the global ceramic substrate market size is expected to reach US$10.96 billion in 2029, with an average annual growth rate of approximately 6.57%.

Enquiry

Enquiry