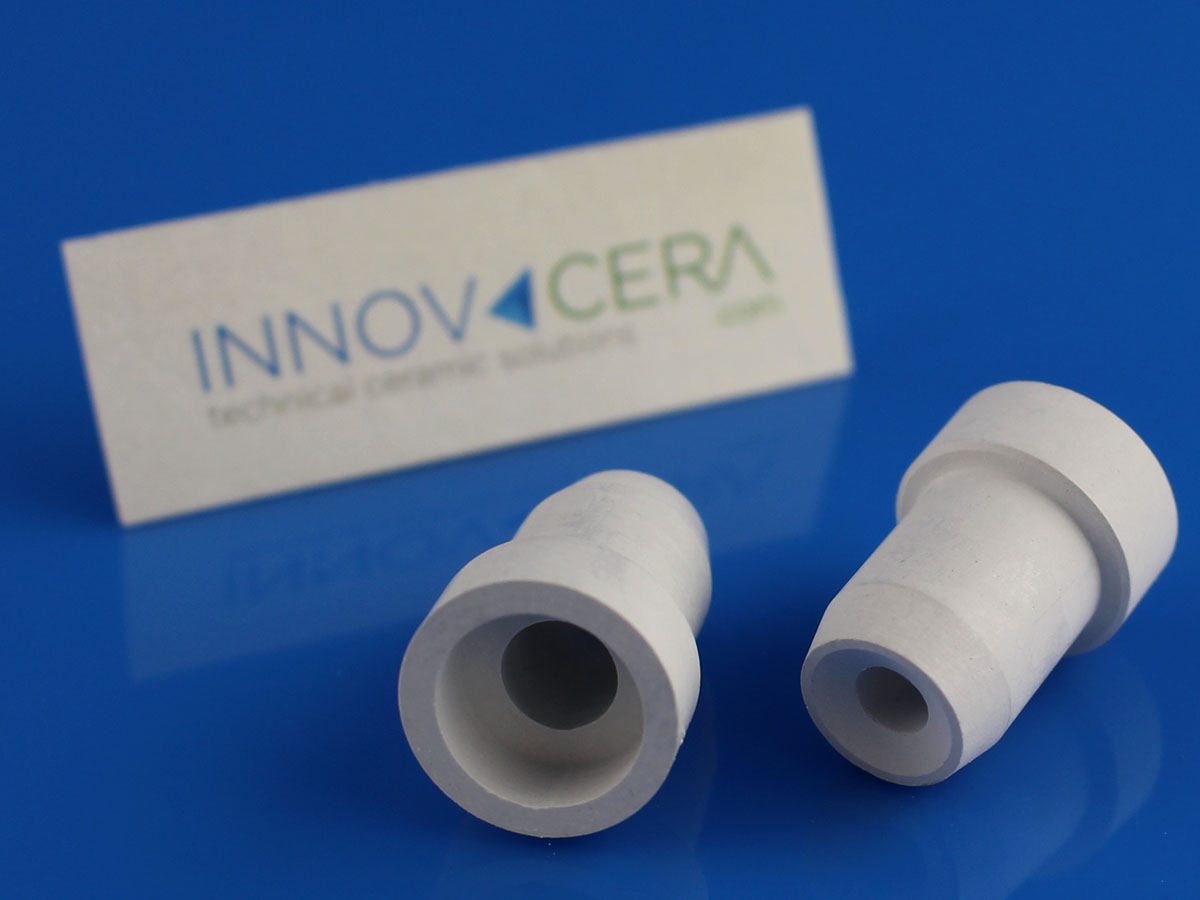

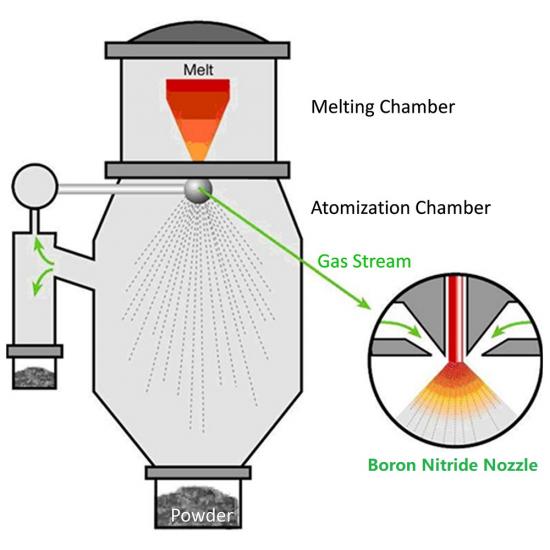

Boron Nitride is an ideal material for atomizer nozzle due to its high strength, high melting point, high toughness, outstanding thermal shock resistance, excellent machinability, and low-friction properties.BN nozzles for the atomizing process may ensure a continuous flow with no blockage or breakage.

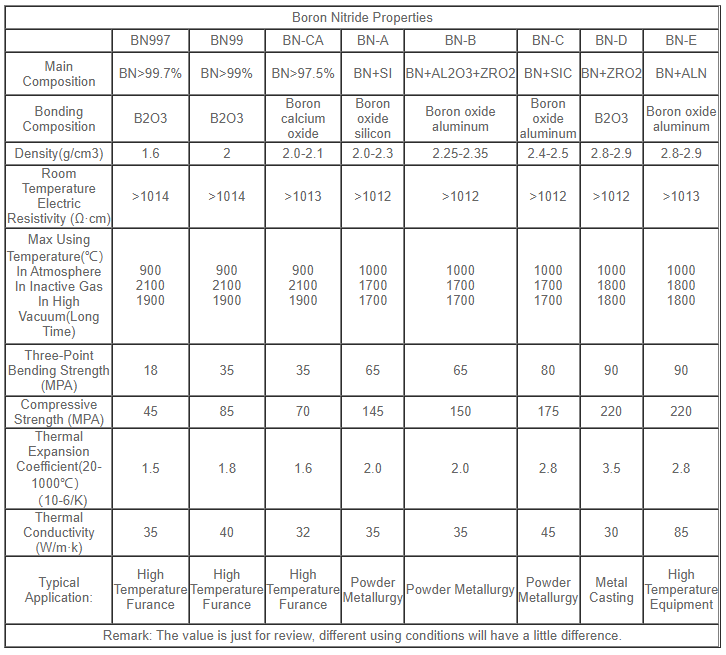

INNOVACERA provides different grades of BN materials as below. The best choice for metal powder gas atomization should be BN99, BN-B, or BN-D.

It is an advanced ceramic material with a high melting point, is tough enough to prevent cracks, has high thermal shock resistance, and is easily machinable. In addition, molten metals cannot ‘wet’ the surface of boron nitride, which means that it is not easily clogged during the atomization process.

Under a high vacuum, boron nitride can survive up to 1,750 °C. A gas atmosphere can push this even further to 1,900 °C. This means that boron nitride will remain solid through the melting of most metals. Boron nitride has a very low thermal expansion. Together with the high heat conductivity, this ensures that the material has very high shock resistance. It can easily withstand the rapid gradations in temperature inside the atomizer. It does not break or crack under thermal stresses.

Enquiry

Enquiry