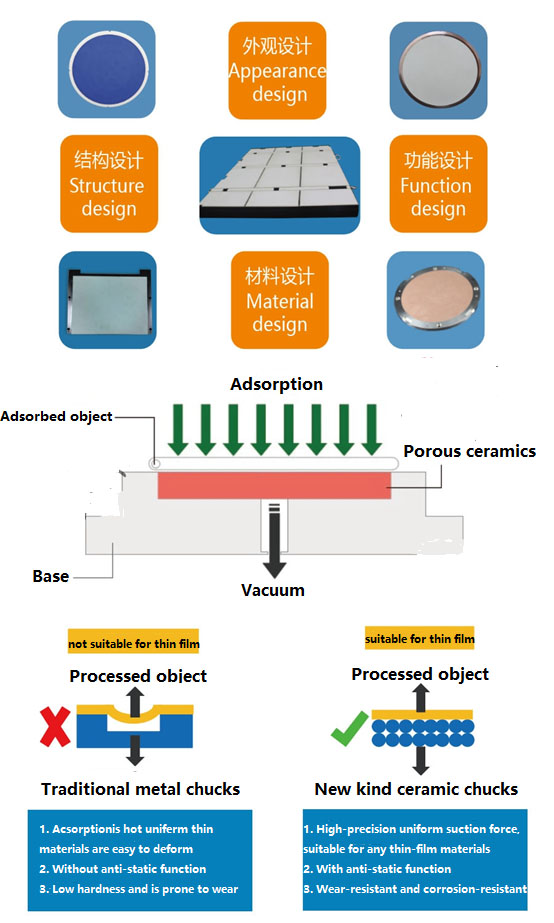

The electrostatic microporous ceramic chuck is a key part of the deep silicon etching machine. The electrostatic adsorption technology used is an advantageous technology that replaces the traditional mechanical clamping and vacuum adsorption methods. It has a wide range of fields in semiconductors, panel displays, and optics, application.

Features of electrostatic microporous ceramic chucks:

1. Can be used simultaneously in the atmosphere and vacuum environment;

2. Can adsorb conductors, semiconductors, insulators, and porous materials;

3. Simplified clamping and handling mechanism, low energy consumption for electrostatic adsorption;

4. The adsorption force is uniform, and there will be no local force during adsorption;

5. Light and soft support for large-area thin film, and there will be no scratches and wrinkles during adsorption;

6. It can be opened and closed quickly, and no potential is generated on the back of the object, and the surrounding dust is not absorbed.

Application fields: vacuum bonding in the panel industry, semiconductor chip packaging, microelectronic integrated circuits, precision optical component manufacturing, solar photovoltaic.

Enquiry

Enquiry