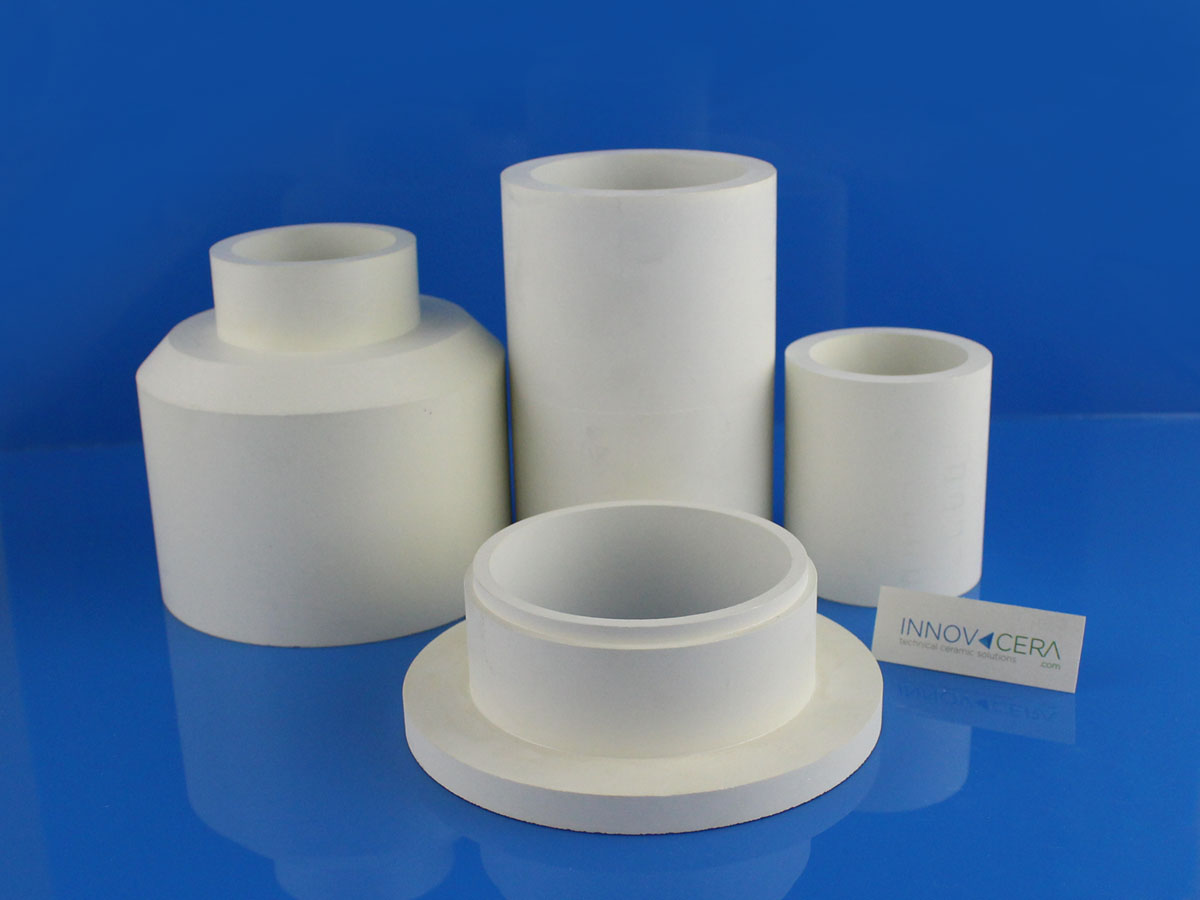

Boron nitride is used for the electrode insulation of vacuum high-temperature equipment.

Matching model: BN-99, BN-AL

Advantage:

- Temperature resistance up to 2000 degrees;

- Thermal shock resistance;

- High electrical breakdown resistance (3-4 times that of alumina);

- Corrosion resistant to carbon atmosphere (better than alumina).

Innovacera can supply large size with 500*500.

And the 10 large-scale hot press sintering furnace is the largest production of high-purity boron nitride in China.

Enquiry

Enquiry