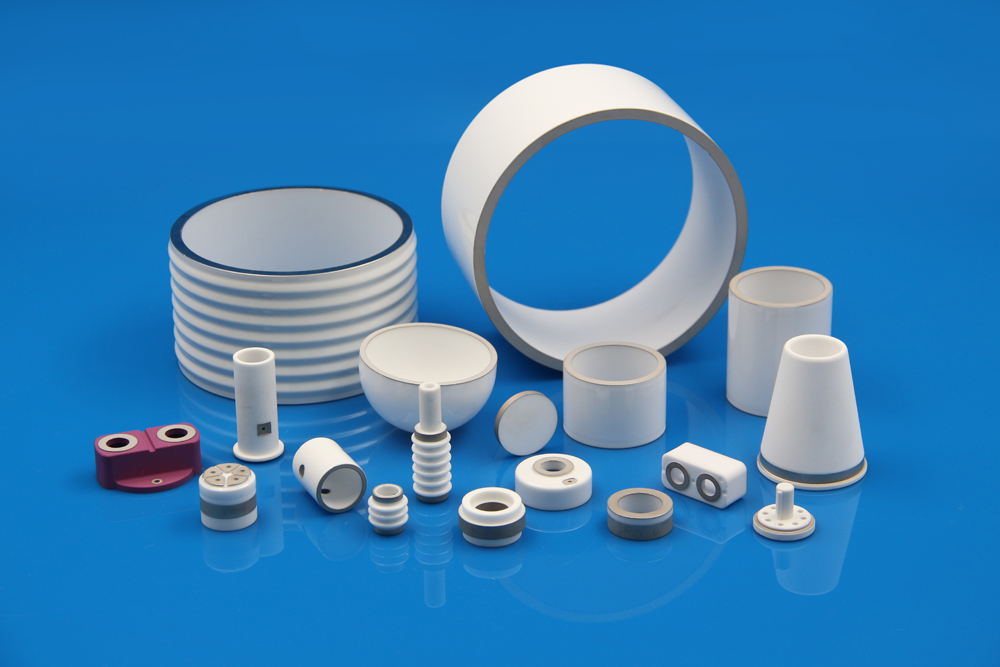

In order to achieve the bonding and brazing purpose between ceramic to metal, ceramic to ceramic, a thin metallic coating will be applied on the designated section of ceramic parts, including the inner diameter, outer diameter, the end surface, or flat surface, afterwards, the ceramic components cured under high temperature, the metallic layer will adhered on the ceramic body tightly. This kind of technical ceramic parts are called as Metalized Ceramics.

Innovacera is a professional manufacturer with over 10 years of experience in ceramic metallization. We can offer you the following services

METALIZATION SERVICES WE OFFER:

Metalization with Moly-Manganese and Tungsten Manganese, most commonly applied on aluminum oxide.

Coating thickness range: 10-40um

Gold, Nickel and other plated materials over metallization suitable for design requirements and improved brazing parameters.

In-house thickness measuring of metalized and plated surfaces through our XRF machine. Certified and Calibrated.

Ceramic to metal brazing – we work with commercial braze alloys, most commonly Copper, Gold and Silver-based alloys. We employ the appropriate brazing method for the joints of custom components based on material and geometry of the parts to be brazed.

Testing capabilities: We perform vacuum leak testing up to 10-9 Torr.

Our custom metalized ceramic components provide dependable solutions for a wide variety of applications in various industries, including but not limited to aerospace, sensors and telecommunication.

Our brazed components are used in a variety of products and systems, including but not limited to, aircraft and spacecraft components, fiber optics, medical components, microwave transmitting tubes, HV electrical conductors, vacuum electronics and vacuum feedthroughs.

METALIZATION SERVICES WE OFFER

Enquiry

Enquiry