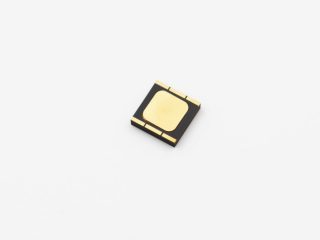

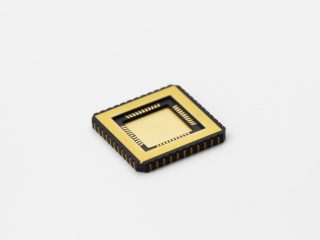

Distinguished by its excellent thermal conductivity, Beryllium Oxide is an ideal material for applications requiring large heat dissipation as well as dielectric and mechanical strength. It is particularly well suited for use as a diode laser and semiconductor heat sinks and as a rapid thermal transfer medium for miniaturized circuitry and tightly contained electronic assemblages.

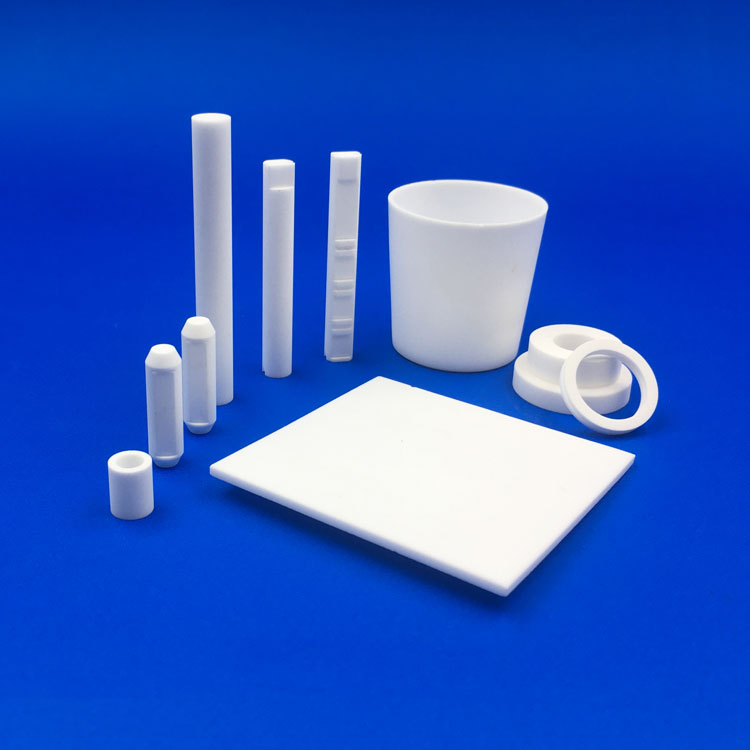

Beryllium Oxide BeO ceramic heatsinks

Properties of Beryllium Oxide (BeO) ceramic:

| Beryllium oxide(Beo) B-99 Properties | |

| Item | Value |

| Dielectric Constant | 6.9±0.4(10GHz) |

| Tangent of Dielectric loss | ≤4×10-4(1MHz) |

| ≤8×10-4((10±0.5)GHz) | |

| Volume Resistivity | 1011Ω·cm(300℃) |

| Dielectric Strength | ≥20 kV/mm |

| Bending Strength | ≥190 MPa |

| Density | ≥2.85 g/cm3 |

| Average Coefficient of Linear Expansion | 7.98×10-6 1/K (25℃~500℃) |

| Thermal Conductivity | ≥240 W/(m·K)(25℃) |

| ≥190 W/(m·K)(100℃) | |

| Thermal Shock Resistance | no crack |

| Chemical Stability | ≤0.3 mg/cm2(1:9HCl) |

| ≤0.2 mg/cm2(10%NaOH) | |

| GasTightness | ≤10×10-11 Pa·m3/s |

| Average Grain Size | 12~30μm |

| Remark: The value is just for review, different using conditions will have a little difference. | |

Typical applications for Beryllium Oxide (BeO) ceramic:

Heat sinks for high power electronics, laser diodes, and advanced avionics.

An ideal refractory material which can be used for both nuclear reactors and very high temperature furnace applications.

Other application in aerospace, defense, laser, medical, nuclear.

Please contact us if you would like to discuss how we can best help you solve those thermal management issues calling for higher performance in your project or new design applications.

Enquiry

Enquiry