Power electronics devices such as MOSFETs, GTOs, IGBTs, IGCTs etc. are now widely used to efficiently deliver electrical power in home electronics, industrial drives, telecommunication, transport, electric grid and numerous other applications.

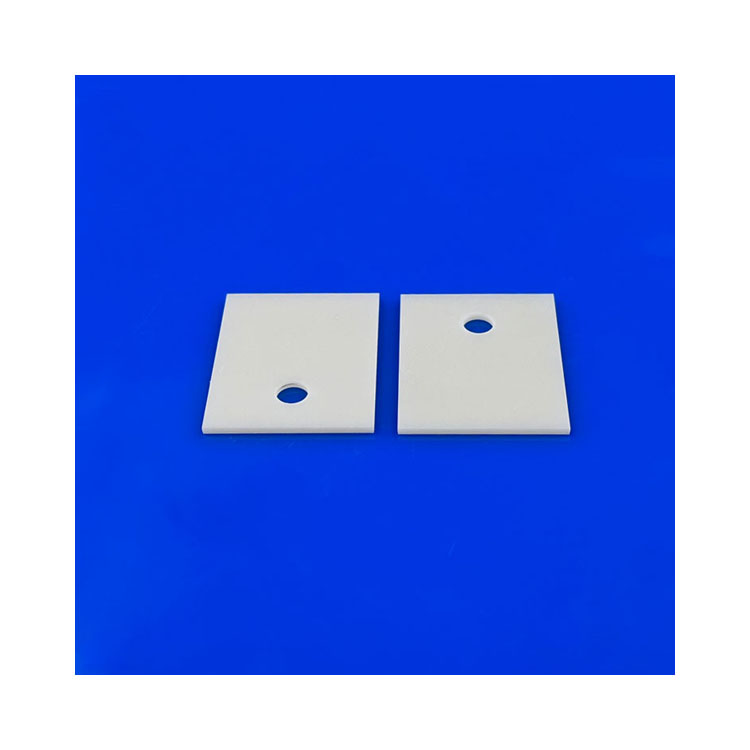

ALN-PLATE

In power electronics, chip-on-heat-sink technology makes it possible to reduce thermal resistance between the heat source (chip) and the heat-sink by (depending on the design) up to a quarter of the value compared to conventional cooling system design.

Thus, ceramic heat-sinks make it possible to achieve power densities that were previously unattainable.

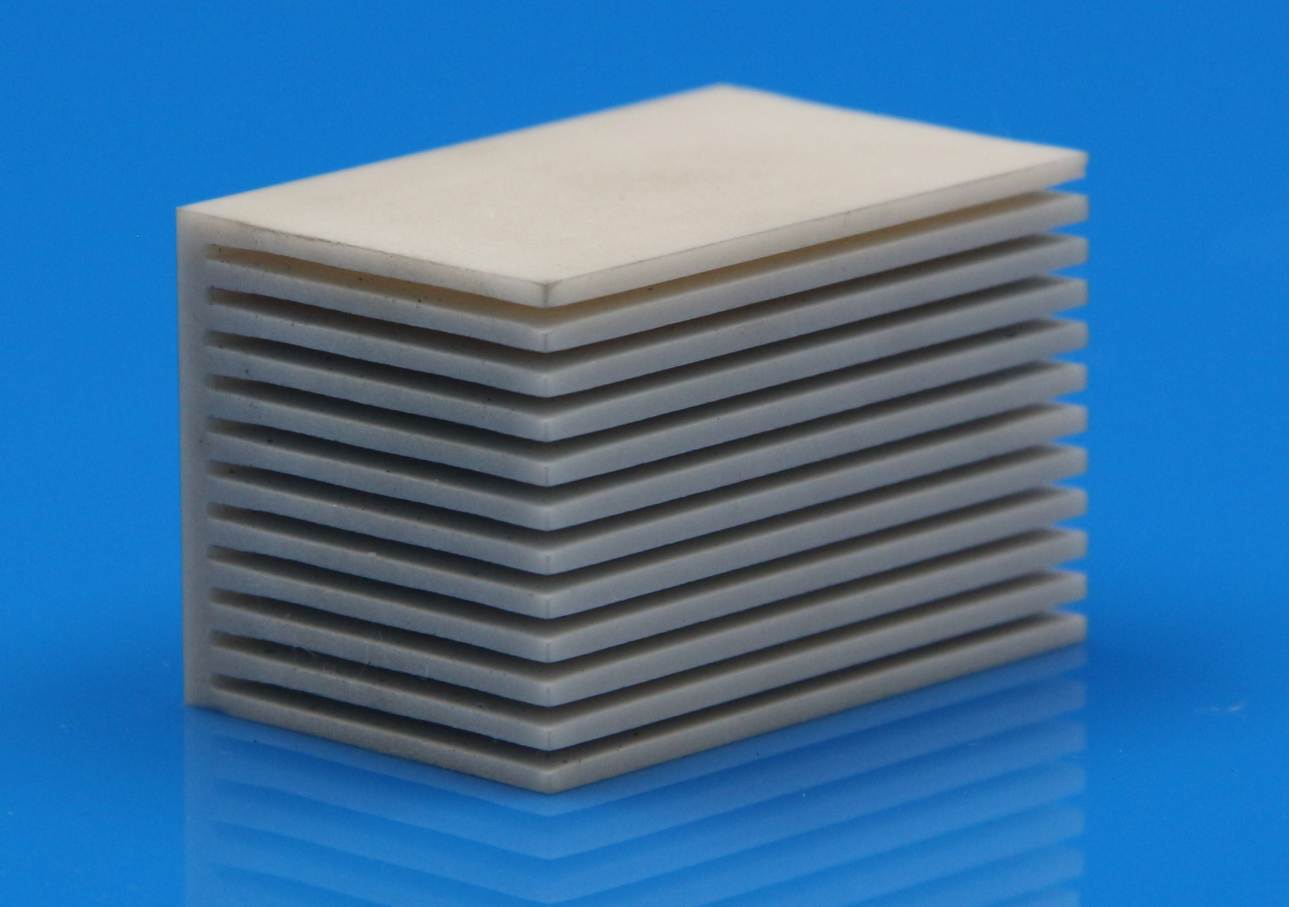

ceramic-heat-sinks

The best material of ceramic heat-sinks is aluminium nitride which thermal conductivity is above 170W/mk, below is the material properties.

If you have more questions, pls consult with us.

| Properties | Value | |

| Bulk Density(g/cm3) | >=3.3 | |

| Water Absorption | 0 | |

| Flexural Strength(MPa) | >300 | |

| Vickers Hardness (Gpa) | 11 | |

| Modulus Of Elasticity (Gpa) | >200 | |

| Dielectric Constant(1MHz) | 8.8 | |

| Coefficient Linear Thermal Expansion | /℃,5℃/min, 20-300℃ | 4.6*10-6 |

| Thermal Conductivity | 30 degree Celsius | >=170 |

| Volume Resistivity(Ω.cm) | 20 degree Celsius | >1014 |

| 300 degree Celsius | 109 | |

| 500 degree Celsius | 107 | |

| Dielectric Strength(KV/mm) | 15-20 | |

| Remark: The value is just for review, different using conditions will have a little difference. | ||

Enquiry

Enquiry