When engineers design seals for electrical connectors like feedthroughs, they typically consider four common materials. At the low end, simple epoxy resins or adhesives suffice. Alternatively, mechanical seals with elastomeric O-rings provide a more robust solution. For applications demanding more, glass seals effectively prevent leaks during extreme temperature, pressure, and humidity variations.

For top-tier performance, ceramic seals reign supreme, boasting excellent heat resistance, mechanical shock resistance, and corrosion resistance. However, the superior performance of ceramics over glass comes at a cost. Ceramic materials are typically more expensive, and ceramic-metal seals require more complex engineering and manufacturing processes.

Innovacera suggests using ceramic seals when glass seals fail to meet demanding performance requirements. For instance, aerospace applications demand high heat and mechanical shock resistance, while medical implant devices require excellent corrosion resistance and biocompatibility. Outstanding dielectric properties are crucial for high-voltage and high-current laser applications.

Advantages of Ceramic Seals

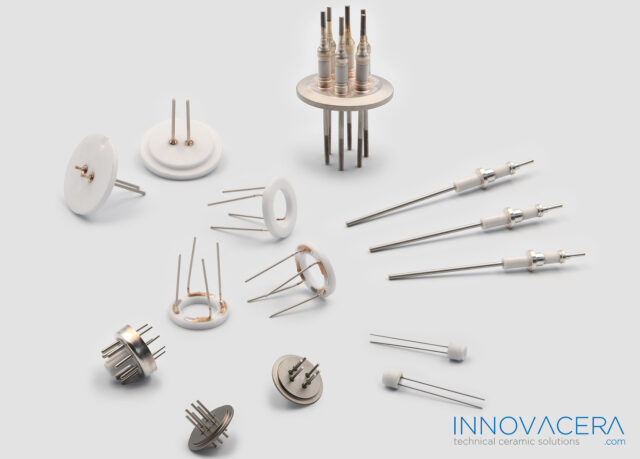

Ceramic-metal seals offer several benefits over glass-metal seals, including stronger hermetic sealing and better electrical insulation properties. Innovacera primarily utilizes 95% alumina, 99% alumina, and sapphire.

Properly designed ceramic-metal seals maintain hermeticity under various harsh conditions, such as high and low temperatures, corrosive environments, high pressure, and high vacuum. Ceramic-metal seals boast an industry-standard leak rate significantly lower than glass seals, indicating superior sealing.

Ceramic-metal seals withstand severe thermal shocks and repeated thermal cycling, remaining stable at extremely high and low temperatures. They exhibit high mechanical strength, making them less prone to breakage under high vibration and high g-load conditions compared to glass seals.

Advantages of Brazing

Ceramic-metal seals use brazing to join ceramic and metal components, producing strong bonding and excellent sealing. Brazing works well for metals and alloys that do not bond well with glass. Ceramic-metal seals exhibit good bonding with copper, copper alloys (CuNi), nickel, and nickel alloys (such as Monel, Alumel, Nial).

Compared to glass seals, the presence of brazing metal between the base metal and ceramic substrate enhances the system’s robustness. Brazing materials are more flexible than ceramics, absorbing some mechanical shocks and helping to mitigate mismatches in thermal expansion between ceramics and substrates.

Typical Applications

Ceramic-metal components play a crucial role in implantable electronic devices and aerospace applications due to their ability to withstand high temperatures, vibrations, and mechanical shocks. They are common in seals for gas turbine engine thermocouples, fuel line components, and fire detection system terminals.

Manufacturing Process:

To prepare ceramics for brazing, the surface undergoes metallization. Innovacera primarily employs thick-film and thin-film metallization technologies to ensure proper bonding and integration of ceramic-metal components. All components undergo comprehensive testing to ensure quality and consistency.

Enquiry

Enquiry